-

Posts

2,235 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Francis Trez Cole

-

-

Tong blanks

in Tongs

Clean looking tongs

-

one of the best mental tricks I use set the shape first you can go back 2 or 3 times to get each area refined. Don't try to complete the Jaw boss and rein in one shot. Go a 1/3 of the way in each step. it helps refine the end shape.

-

The video is great, But you never hit the flat side of the boss with the hammer. The anvil will help make the boss flat. Second I would use a longer rivet to make a a bigger head. Helps keep them strong when twisting. Remember the forge to hold the metal is in you hand the longer the reins the more leverage you have.

-

there is a great chart that has the sizes of all the parts of the tongs. Glenn has posted it try not to recreate the wheel they work. I have made sets using the chart and like the way they feel. The only piece of advice I would give if you use a gas forge you might want the reins longer.

-

I would agree with Thomas. Leonardo De Vinci created a power hammer. There is time for being a purest But you are learning the more you do the better you will get.

-

there are so many great references out there. When making the Jaw,Boss,and rein transition keep your work so that you do not hammer on the side that was against the anvil. there is a fine line between hammered out and finished. check the edges of the anvil that you are using. Also while you are hammering the Boss out increase your angle from 45 to 60 that will round up that inside corner. I always clean up my boss with a file before final assembly.

-

Very nice first set of tongs I like to file the contact surfaces of my Boss's

-

Frosty thanks for the post and comments. Any one interested in Blacksmithing can Join FABA-SW We like to see What other are doing. We started doing the live meeting to keep people safe during these time. Sorry that its so early Here in Florida trying to beet the heat of the day. The graininess came from a poor wi-fi link we went to a hot spot and it cleared up. I always look forward to a comment from a wise sage like you Jerry

-

Joe always well thought out. I have had problems with rebar cracking over the years. mostly from students putting them in water to cool

-

your are headed in the right direction

-

Masonred you don't need an anvil a block of steel will work just fine until you find one you can afford. I started out with the back side of a machinist vice. Then got an anvil. When i teach i have a set of blocks with legs welded on for a lesser term a striking anvil. If a student dents it or chips an edge I can just clean it up with an angle grinder. Had a old Farrier show up to watch me teach at the end of the class he pulled me aside. he was skeptical at first but after the class he said"that's the only way to go" .Farriers use a thing called a Stall Jack small and efficient for shaping shoes. You can make one very inexpensively

-

chris C What type of welder do you have? That can effect the quality of your weld not brand but the type.

-

-

Nice looking tongs. Why is it that now days people are doing the weld at the rounded end. If you look at the old videos they do it on the side not the rounded part of the link

-

you should not use a water can with a cast fire pot. A mop is much safer. Hot cast iron and water = crack.

-

well Viking style tongs have been around longer than flat jaw tongs

-

turn that monster mall in to an oliver hammer. It can be built with a wooden frame Then you will have a helping hand

-

maybe it was the available stock at the time the rolling mills all produced round stock. So the style was developed out of practicality.

-

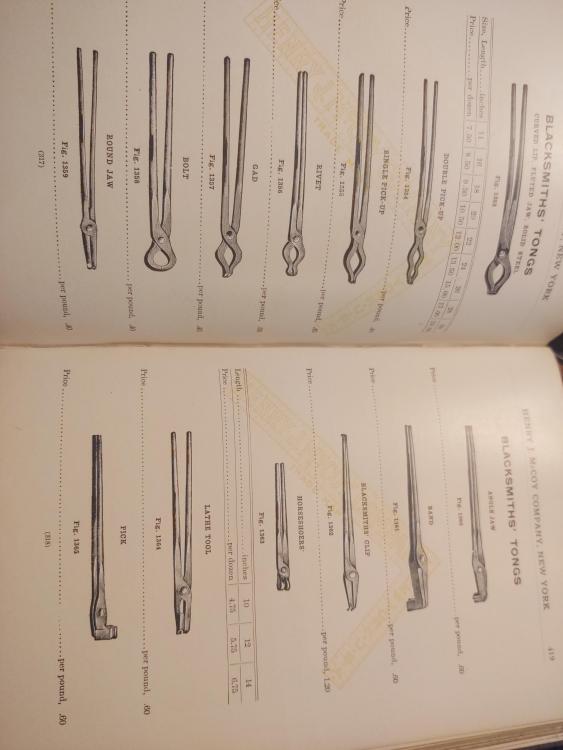

now that's going in the right direction Dimensions for Standard Tongs.docx

-

that is a good way to start. Keep working at it. practice half face hammer blows and you will be making tongs in no time

-

nice tongs

-

-

the biggest problem I have seen with people trying to forge weld is heat. You have to get a good saturating heat. That means you metal has to be the same heat and the right temperature. With out over heating.

-

Arftist Nope I know just how many I can deal with at one time

Damascus Copper or Brass added to knife blade?

in Knife Making

Posted

In the last few years I have seen Copper layered in to a knife blade. I get the principle. Has anyone ever used Brass? It has a lower melting point so in theory it should work. To that point you could use both in different layers . I am planning to play with it soon any tips would be appreciated.