-

Posts

158 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Sanderson Iron

-

Well, that is true, but I really like old machines and was wondering what else is out there from the old school that would be less annoying. You have a good point, but there's no way for me to make an old machine--just can't be done. That's my good point. Okay guys! So I had a frustrating day with a machine that annoyed me. Anyone else ever have a day like that? All in fun, fellas.

-

Now Jim, that STS of yours is something to think about! It bends on the vertical, which I'd bet has some advantages keeping things in line. I like it. It looks nice and rigid too, and by bending vertically, it has the floor to back it up. Hmmmm... I thought I'd be back up in your woods long before this. Seems like I get busier in the spring than I remember in the winter, and then I'm behind all summer. I use the bender for general bending and straightening cold up to, oh, 1/2" by 2" and hot on up to 2" round. I'd much rather straighten under the hammer, of course, especially taking a lateral curve out of a bend which is supposed to be on a planarity. The thing that bothers me about the Hossfeld is all the flex in it. It's pretty much impossible to form a nice slow curve in flat stock and not have it become a slow spiral. On my tables' frames, that's a problem, of course. I'm making a demilune frame now for a console. I make a template, carefully bend the iron to the line with the Hossfeld, then I have to go over to the vise, take the twist out of it, which ruins the bend of course; so it's back and forth, back and forth. If the Hossfeld were made of more meat (like Jim's bender!) its frame wouldn't twist, and it'd do better work. I'd like to see a "scrolling pin bender" which you mention. Sounds interesting. For repeated bends I use the shaper. That's consistency, but it doesn't allow free-forming and general bending.

-

Has anyone seen an antique bender like--or better yet not like--a Hossfeld? Are there any old quality versions that are made stiffer and better and make their users smile instead of cuss? Old machinery makes smiles happen in my world. I cannot stand a Hossfeld, but I have to have the darn thing because there're some things only it can do. But dagonne, that's a poorly made, boingy, annoying thing! Mine's a No. 2, and I bought it new, so it's in as good a shape as ever was intended (as if "good" can apply to one at all). Ugh. This is why I bend with a shaper or under a hammer as much as possible. Gee, this is sounding like one of my air hammer rants. No offense to you loyal Hossfeld people, if any exist. Joel

-

Ha ha! Yes! I guess I'm the other way around. I drive a horse to work daily, and my wife doesn't like it when I drive a car because I forget that without a horse I have to look where I'm going! That can be a problem. When you get your press, make certain you know its rated speed. Don't trust the pulley/motor that comes with it to figure that out. Then run it slower at first until you get used to it. If you mess up then, it'll be no big deal. I ran mine at 60 RPM for awhile, then sped it up to 100 later. Look for one with a hole-thru table. Mine is solid, and it's a handicap; a hole lets you do more, and not just punch. That hole can be used for a drop-in sub press or shoe, and those often have built in springs for cushion and extended die contact (memory issue). Don't think in black and white and absolutes, and you'll be a lot more successful with it. A press can do about anything. Yes, but you see, hot iron is their normal use, just not their common use. These things go back nearly to the beginning of industry and are seen in old photographs alongside hammers. This is not my idea, you know. By the way, that anchor's a really nice bit of drifting.

-

Is it okay to take Michael's post and hijack it to a general discussion like this? I feel like we should focus on the guy's question; but maybe by reading what we have to say, he'll get something out of this. I hope? Not sure who's right and who's wrong here anymore. Ha ha! But I am going to make the following statement and then clarify it: A punch press can do anything a power hammer can do--anything. --Joel Sanderson, April 23, 2018 Some operations that are difficult with a hammer are a breeze with a press, and some operations that are a breeze with a hammer are difficult with a press. The two machines compliment each other very well that way. Have you punched many holes with your hammer? (punched--not drifted) That's a lot easier with a press. Slot punching round bars? Piece of cake with a press--centered. Heading? Riveting? Easier and more consistant with a press. Starting a tendon? One tool no matter the stock size. The list goes on and on. A hammer can do about anything, right? but not everything is best done with it. Same with a press. Forging tapers with a press require more complicated tooling than with a hammer, but it can be done. Swaging is not ideal with a press either, since it's slow and has more die time. So... Either can do what the other does, but neither is always the best machine for the job. Does this make sense? I'm not sure why you'd insist on not adjusting the press. You wouldn't even want to do that with a 50 pound Little Giant--and maybe not a 100 pounder, though I've never run one. A press is a different machine. Don't treat it like a hammer, or you'll be very disappointed.

-

I'm irresponsible? This is hysterical. I just gotta ask, have you ever forged with a punch press, Exo313?

-

I would say Thomas and Frosty did challenge my statement that a punch press can do anything a hammer can do--with exclamation points to boot. (I didn't take yours that way though.) Over and over we hear the claim that punch presses are worthless to blacksmiths, and that holds our craft back--holds people like Michael back--because they have great potential at a very low cost.

-

Measure. Run it the speed intended. The flywheel has only so much energy (if you run it the correct speed) and the frame and crank are engineered to withstand that energy, probably by at least a factor of 3. You can stop a press (and I have), but it's more of a headache than a nightmare. Sometimes it jams; sometimes it bounces back; but I try to avoid the problem in the first place by using it sensibly. You can do things to kill a hammer too, and they also can be dangerous machines, but those are no reasons to keep us from using them. There're lots of welded hammers out there. Two of my hammers have had major repairs--welded or brazed parts that broke under the machine's own power. Does that mean power hammers are no good because they self destruct?

-

Frosty, do you have a punch press in your shop? I'm gonna guess no, just like I'm gonna guess (by his silence) that Thomas doesn't have one either. So here we have two people who don't have a punch press and probably have never used one for open die forging announcing that it can't be done. Yet, I've been using one for just that for almost twenty years. (I still haven't seen it explode.) Videos are hardly my shop's focus, but I have a few. You're free to look at them any time you want; and while you're at it, take a peak at my work. Everything leaves tracks, and my press has left lots of happy little tracks all over my iron. Michael, if you're looking for a machine to make damascus, a punch press will do each operation: weld, draw, cut for folding (and fold if you want to), weld again, repeat. Like I said, a press can do anything a hammer can do. I don't make damascus anymore, but from my experience with both that and a press, I'm gonna say that you probably would get better consistency with a press than with a hammer or similar percussion or manual stroke machine. And the cost is right smack-dab in the I-can-afford-to-experiment zone; and maybe even the I-can-have-more-than-one zone. Feel free to get ahold of me with questions. I don't want to get into a shouting match on a public forum with well meaning people who haven't done this. (edit off site link) a video will probably show up there eventually. Just search for my name and business. Best of luck in your decision. Joel Sanderson You incorrectly assume that because he has not been online to read and argue your posts that you are correct? that is a flawed premise

-

Thomas, do you have an OBI in your shop? Any kind of punch press?

-

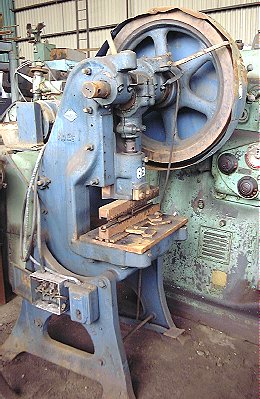

A punch press, (toggle press, O.B.I) will do anything a hammer will do, no modification whatsoever, and you can get em for scrap or less around here. Don't know about Washington. Go for between 35 to 75 tons. I've stuck on a picture down below of a random OBI just so you know what I'm talking about.

-

Protective cover for bottom die

Sanderson Iron replied to beaudry's topic in Power Hammers, Treadle Hammers, Olivers

I don't know if this will help at all, but at least it's information. I looked up what I made the dies out of for my 100 pounder: one is H13; the other is 4340. They are 3 1/2" wide and 8" long. The H13 die is a bolster die and is heat treated to RC 50. I think that was all the harder it could be made. The plain flat die is hardened to between RC 50 and 55. They both have dents in them though. I think your plate's an excellent solution. I might do that myself. Thanks. -

Protective cover for bottom die

Sanderson Iron replied to beaudry's topic in Power Hammers, Treadle Hammers, Olivers

I'd take them someplace to be Rockwell tested. I wonder if they're hard enough if you're able to file them. If they're under C50, send them somewhere to be heat treated. I'll try to remember to look in my records today to find out how hard the 4140 bottom die on my 100 pounder is. However, I've had the same issue with my 250's die when it's had a swage in one place awhile. That die came on the hammer, so I have no idea what it is. My swages are 5160 if that matters at all. That's because it's a variable speed, variable stroke length, come-with-a-brake for instant stopping Beaudry. Beaudry guys all know their hammers are the best in the universe too. (Not just the known universe, but the whole entire thing.) I'd like to have one, but I already know my hammer's the best in two universes, both of which are unknown. -

Protective cover for bottom die

Sanderson Iron replied to beaudry's topic in Power Hammers, Treadle Hammers, Olivers

Yes, I've had it happen, but it took a very long time with the same set-up to be noticeable on the die. Mostly it's the bottom of the swage that pits. Are you making your swages? Are they annealed? What is your bottom die made of, and is it heat treated to RC 55 at least? I like your solution. Thanks for sharing. Tsk tsk. Shows how small your universe is. (A one speed hammer. Sheesh!) -

Best drill bits for 5160 steel.

Sanderson Iron replied to ZachNiedjalski's topic in Drills, Post drills, Mag drills, etc

A pilot hole will help a lot if you can get your speeds right. Don't know what you're working with. -

Best drill bits for 5160 steel.

Sanderson Iron replied to ZachNiedjalski's topic in Drills, Post drills, Mag drills, etc

Don't know if it's an option, but any 'ol HSS drill will handle 5160 if it's annealed. (Well, that is, if the drill's sharp.) Use lard oil if there's a problem. I have good luck annealing 5160 by heating it to above critical, letting it soak in the fire a few minutes, then burying it in wood ashes overnight. Usually the next morning it's still too hot to touch but soft enough to machine. Joel -

5160 has been my main steel for forging tools for many years. I've made many swages and fullers from it, and it lasts very well. Many of my spring fullers are one piece from 5160, and it works well for the springs too. (Others have 5160 for the die body with A-36 springs welded on.) Be sure to anneal it when you're done. In my experience a drift made from 5160 does not work well at all, because it galls quickly. The heat transfers into the drift and rips the surface apart. This pulls your work down into the hole and doesn't make a clean hole like a drift that's smooth--not to mention it takes more power. I haven't used the other alloys you mentioned for drifts, but I expect they would do that too. Molybdenum in the mix works best for drifts, like the M-series high speed steels. I usually add a dollop of mig weld to the top of any drift made of HSS so I don't dent the hammer die. 5160 is a deep hardening alloy, so you need to preheat it before you weld it and then keep it hot to let it cool slowly. Otherwise it'll crack apart by the weld. I've made a lot of detailed, cut dies from 4140. Seems to last as long as I need it to. Again, it's annealed when I use it. It also works well for tongs, though most of mine are 5160. 4340 is a pain to cut and machine. I have a good supply of that as well as 4350. I avoid the stuff unless it's going to be forged to shape and never drilled or turned. 1045 makes decent tongs. Again, don't expect it to hold up with a lot of heat transfer. It's less than 1/2% carbon--the rest is iron--so it's pretty low alloy. Just to help you choose your steel, keep in mind that most of the wear on power tooling is from abrasion, not distortion. Fire scale is gritty stuff, and hammering (and pressing) is gobs of pressure, so between them the dies are eaten away wherever there is flow and less where there is not flow--like directly in the die center. I don't know much about hand tools, but I expect the same is true. Joel

-

Power hammer forging rivets,

Sanderson Iron replied to BeaverNZ's topic in Power Hammers, Treadle Hammers, Olivers

That's some nice action you're getting with that hammer. I see why folks like Masseys. -

Little giant issues

Sanderson Iron replied to Ranchmanben's topic in Power Hammers, Treadle Hammers, Olivers

Aww, that's sad. -

Little giant issues

Sanderson Iron replied to Ranchmanben's topic in Power Hammers, Treadle Hammers, Olivers

Sounds like your spring tension's not in sync with the speed. You should be able to walk up to your hammer and step on it and immediately get full speed. If the tension's tight and you hammer slowly, the spring can bounce the ram back up before it strikes (flutter); if the tension's light and you hammer fast, your blow will be dead and racking. Just looking at your video, it appears to me your spring tension's too light; though that'll give you more range in the stock height at a given ram height. In general, I run a tighter spring than my wife doing the same work, because I tend to run the hammer faster than she's comfortable with. With a loose spring, you can just plop that ram down if you want to plop it on a tool or something. The spring tension's an important adjustment, and there was a reason Little Giant made it easier to adjust on the newer models. A Little Giant without a brake can make decent single blows if you loosen your spring. It can be made to set the ram down on a tool to push (drifting), and you can make really slow, tapping strokes (grooving, lining, etc.), but be sure to tighten it back up before you hit fast. Just play with it, and you'll figure it out. Mr. Beaudry's old style hammer with the wrap-around guide doesn't work with as well with a lighter spring tension as the newer version does. I don't know why, but that's my experience. That's interesting, Beaudry. I like heavier oil. In the summer I'll run heavy way oil, and I never run less than 30w on any of my hammers. Just experiment, Ranchmanben, and find what works. -

Sounds like a good idea, Jim. I bet it would be more flexible, wouldn't it? I'll make new parts for this piece, but since the show is coming right up, I'll probably have to leave this table with plain steel for now. Thank you very much for the offer to take me over to your friend's place. If I saw the process I'd understand it better and probably accept it more.

-

It's 1018 in 16 and 11 gauge. (At least I was told it's 1018.) This guy coated it first in the wrong color, then in the color I wanted on top of the first color after I corrected him, and anywhere it has two coats, it's popping off. Some other sample parts with a single first coat, and the back of the parts I need, are not popping. I'm annoyed that he messed it up so badly. Maybe I should give him another chance, but he took two and half months to do what he did, wrong, so how long to get it right? I've got a show this piece is supposed to be in the end of this month. I guess I'll make new parts and leave them iron for it. But I want to find the answer for other pieces. I think it has potential, though maybe Jim is right and I should try powder coating. Hmmmm....

-

Yes, the glass enamel coating is what I mean. Thank you, Thomas. I guess I can mail parts to Mexico just as easily as anywhere else, though there is the ethical/nationalistic/patriotic idea of keeping it in the States. Thank you, Jim. I don't know why, but there 's something about paint that I just can't quite accept. I can't put my finger on it. Why would a glass coating be better? I haven't defined it for myself. I've heard it said that you can't even tell the difference between porcelain/enamel and a good powder coat. I just got some parts back from a place in Illinois, and they're just terrible--actively flaking off as it sat on the table, sending shards of glass to the beyond. Maybe it's not a good idea at all, I don't know; but I'd like to try another place before I give up on the idea.

-

Anyone know where a person can send parts to be enameled?

-

In theory, not in shop. Metal is not perfectly homogenous. If you have it, use it and see how it works. That's what shop knowledge is built on. You'll learn its limits better that way. Keep in mind it's an air hardened steel, so if it gets read (like using it as a hot drift, slit, etc) it's probably gonna harden, like it or not. Here is what little I know about its chemistry: the carbon is what makes it hardenable, but it is really high, approaching cast iron (which is 2% typical minimum, if I recall); the chromium will help it harden throughout (I think the vanadium too, but I'm not sure); and the molybdenum will keep it hard at high temperatures, which makes it hard to forge. (Mo is used in tool steels to retain a sharp cutting edge, which heats from friction.) Here is what's in D2: Carbon 1.4 - 1.6 Chromium 11 - 13 Cobalt 1 max Iron Balance Manganese 0.6 max Molybdenum 0.7 - 1.2 Phosphorus 0.03 max Silicon 0.6 max Sulphur 0.03 max Vanadium 1.1 max More information can be read here: http://www.suppliersonline.com/propertypages/D2.asp I hope this helped, and I hope my help was accurate. (Joel)

- 20 replies

-

- tools

- air hardening

-

(and 1 more)

Tagged with: