-

Posts

664 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by DanielC

-

Personally i find the horse stall mat under my 50# to give too much. I regret putting it under there actually and plan on removing it lol. I feel like 2 sheets of 3/4" ply glued together would work a lot better. I have Fabreeka for my Nazel 4b. The going rate of it per sq/ft is $300-$400, but it and material like it are the best choice.

-

Manipulating a big hammer, installation

DanielC replied to Jspool's topic in Power Hammers, Treadle Hammers, Olivers

I concur on pouring a good foundation. I poured 1.5 yards under my 50# Murray, and plan on pouring 16-20 under the Nazel 4B when I install it. With bigger hammers that I have been around the isolated foundation is a must. Especially as it appears this is in a shop connected to your house. My 50# mechanical is rock solid on its 3.5' thick foundation. The only indication that it is running is the smacking of the material with the top die. I also do not suggest dampening with a rubber material. Stick with lumber. If I remember right, your size is a bit of an enigma for the IK. Most of his tup weights were smaller in his production and were closer to a 20:1 ratio. Not to say 16:1 is bad. My Nazel with sow block and bottom die on the anvil is around 19:1 ratio. A lot of other hammers dont even come close to either numbers. If I were to own a hammer that was not self contained like this class of hammers, the IK be the one. I ran the 110 at Kerry's for like 3 minutes, and it was a beast. Very ridgid I remember thinking when it would hit. -

First Crucible Steel Run, and Forging.

DanielC replied to DanielC's topic in Smelting, Melting, Foundry, and Casting

It is interesting to note that i only became interested in smithing at all after i watched the first airing of Ric Furrer making a crucible steel viking sword on Nova. From there my journey started, and years of constant study, and experimentation and work has lead me here. 50 smelts in, over 60 orishigane runs, and now this. In 2 weeks or so time i have made 4 crucible steel ingots, with at least 20 hours of forging time involved altogether. -

First Crucible Steel Run, and Forging.

DanielC replied to DanielC's topic in Smelting, Melting, Foundry, and Casting

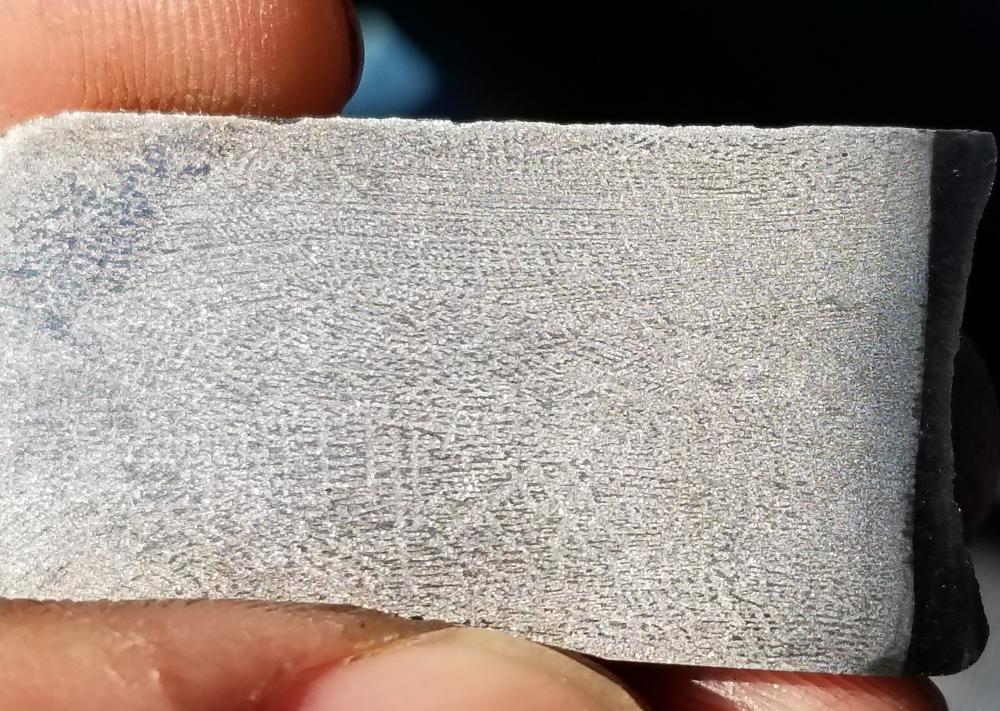

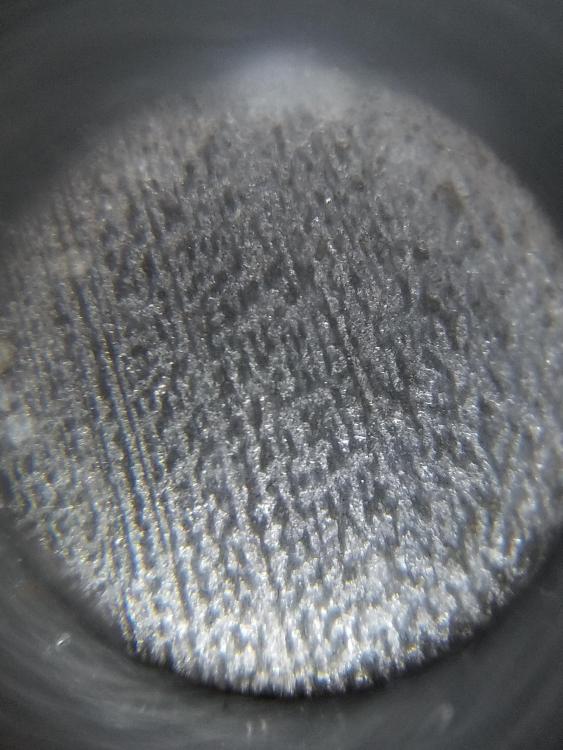

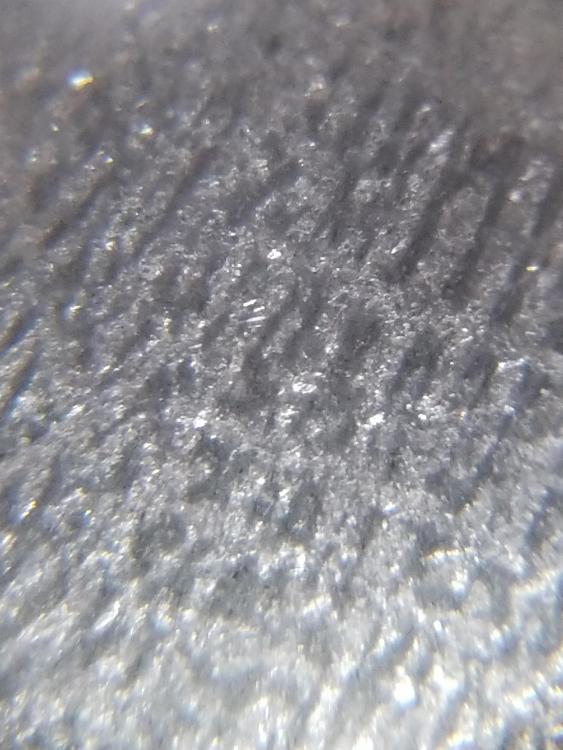

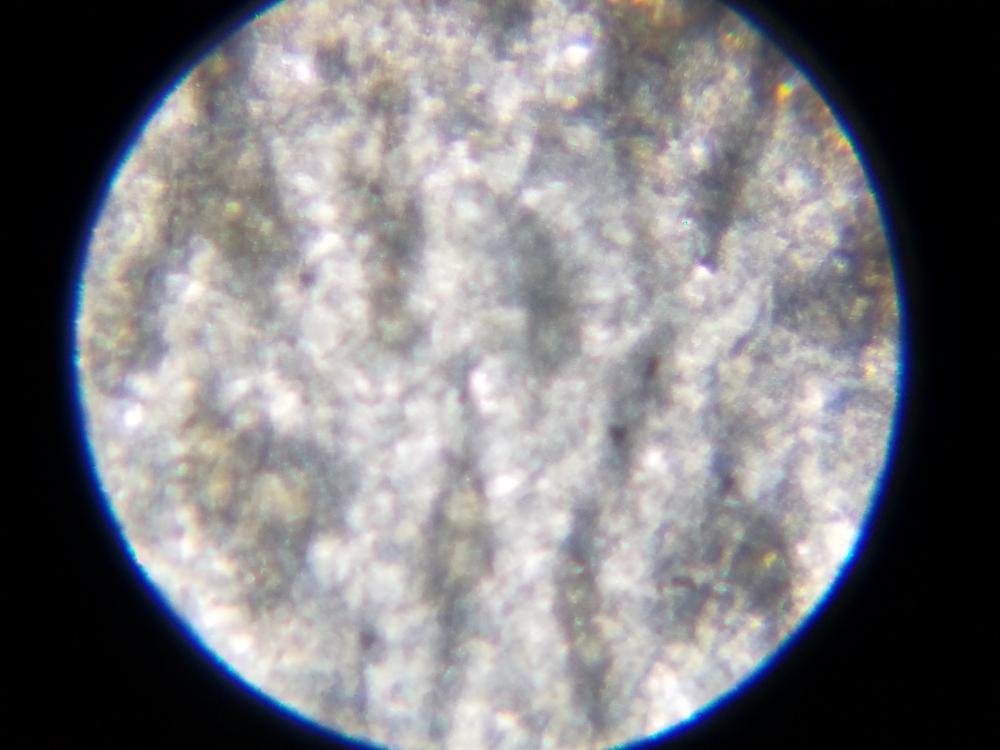

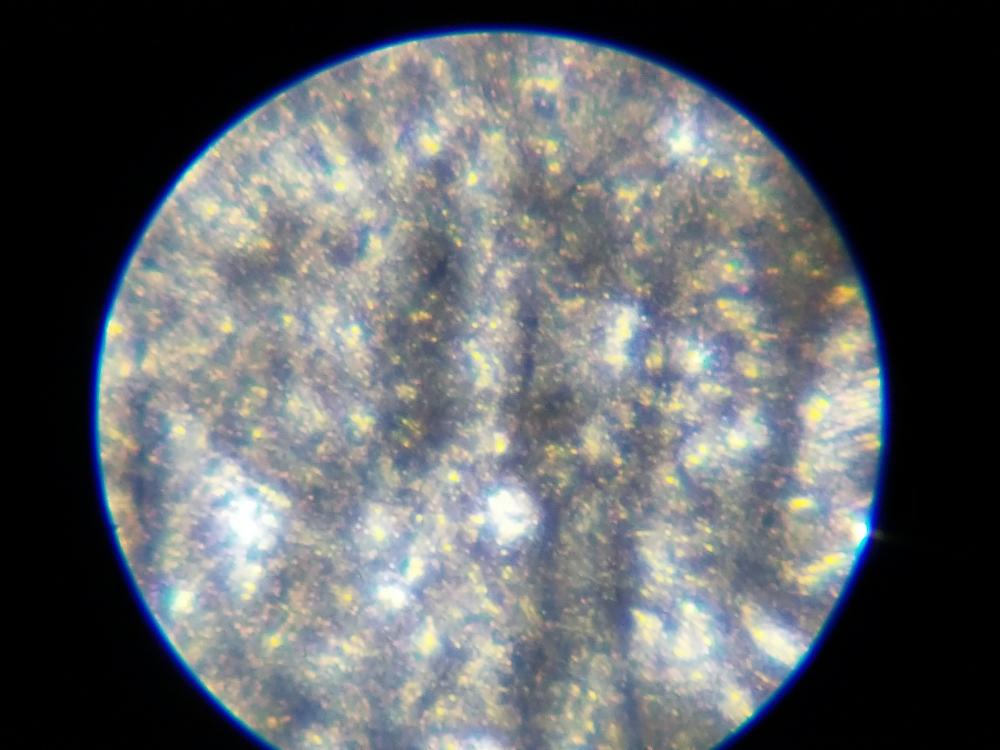

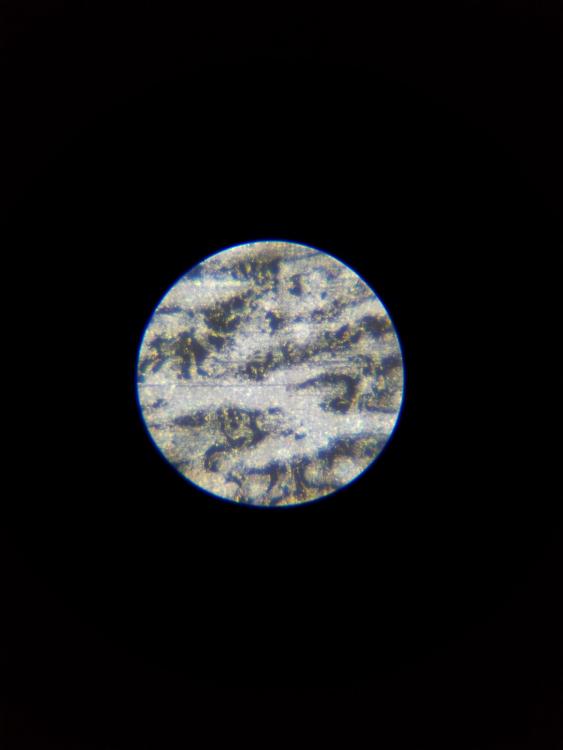

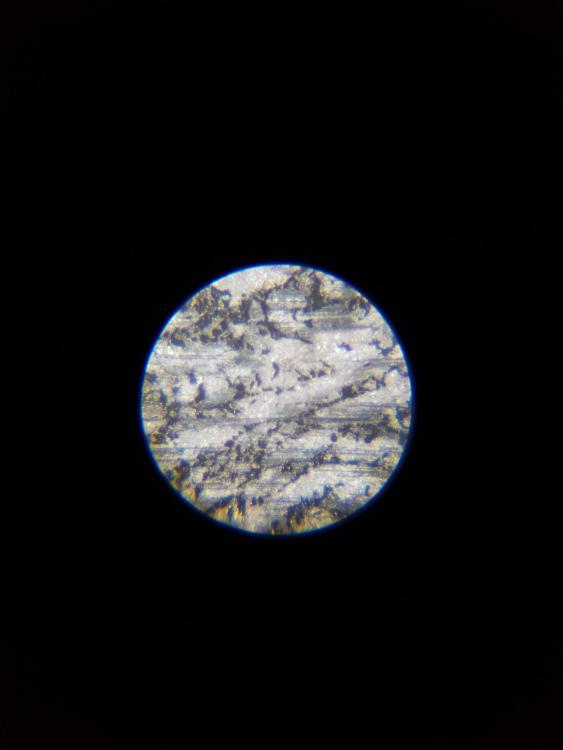

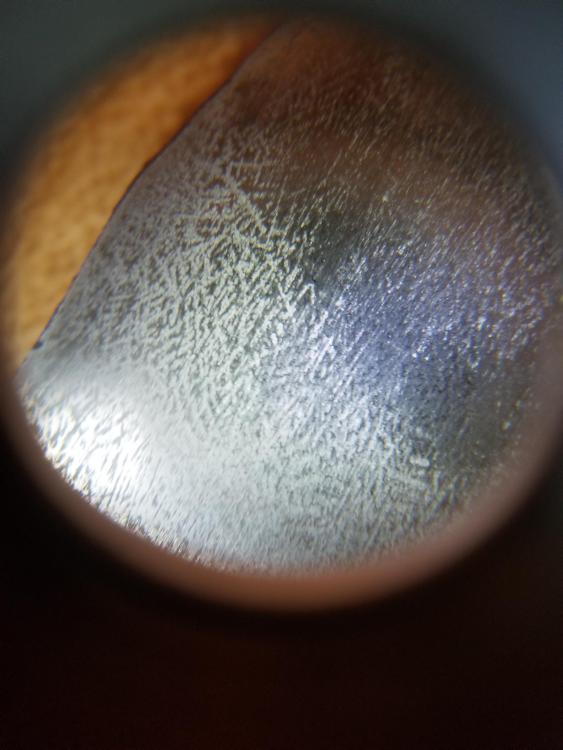

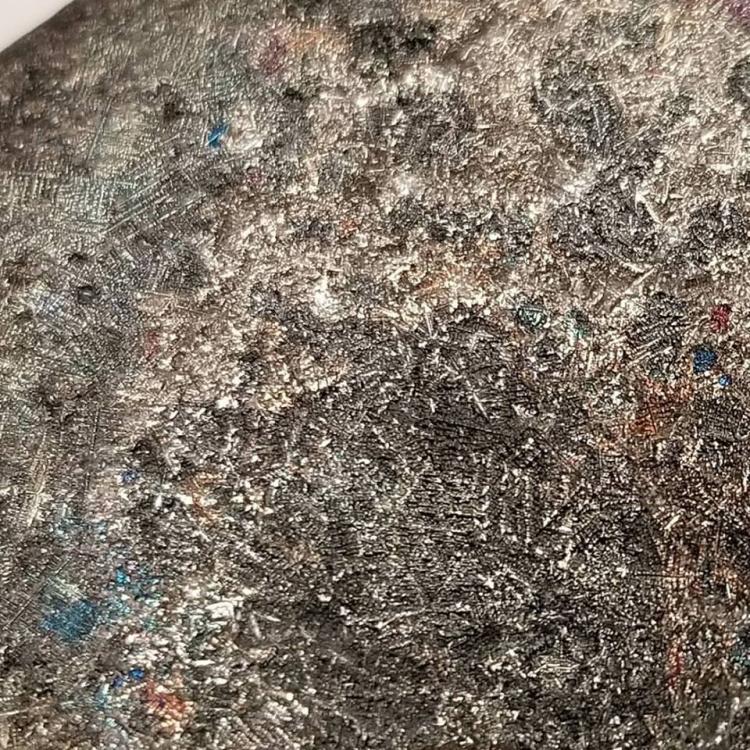

So a few glaring issues with my bar. First being working at the temp i was at, was not hot enough to dissolve the dendritic structure due to the carbon content in my bar. It is hovering around 1.9-2.0% Carbon. What this means is that i have to forge the bar.down further another 100-200F hotter probably. This is the structure on the outside surface of the bar currently. To find the correct temp to work this at for sure, i have cut 5 sample slivers. Each of 3 will go in the forge seperately at 50F differences and noted when the dendrites in the formcof cementite will dissolve. 1 other being the control sliver, and the last being a portion enough to send for compositional analysis. I then polished and etched the control. 60x & 100x These were honestly etched in the wrong etchant as ferric doesnt reveal all of the microstructure. This is an example as i am told by several leading experts in the field of high carbon crucible steel and wootz, that this is still a dendritic, even spheroidized structure. They must be dissolved and worked at rhe right temp in order to precipitate out into cohesize banding structures as is seen in watered steel, or wootz. The new structure at that point is mechanically different for the edge of a blade than a dendritic structure. -

First Crucible Steel Run, and Forging.

DanielC replied to DanielC's topic in Smelting, Melting, Foundry, and Casting

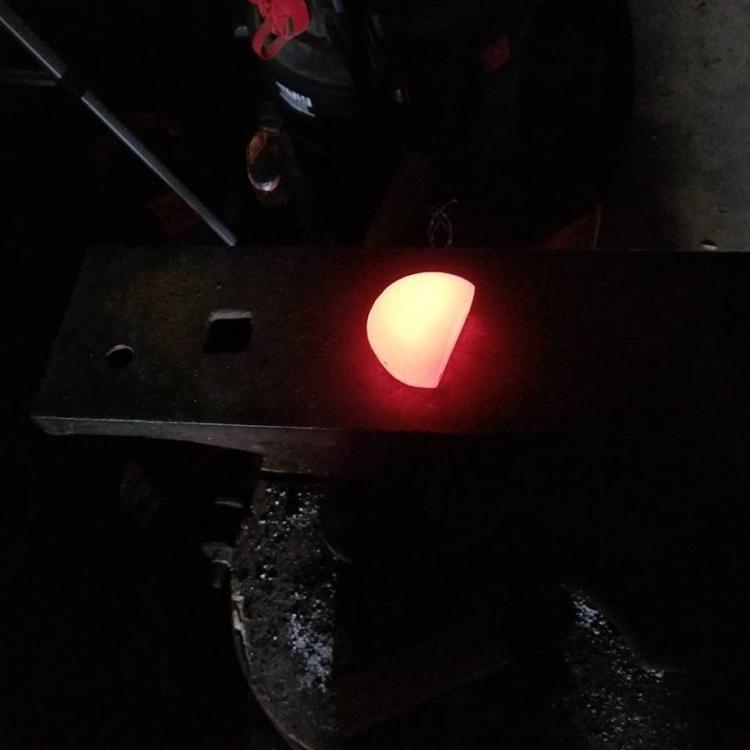

Forged this out some more. The carbon content based on the temps it is wanting to work at are placing it around 1.8-1.9% C by estimation. Dissolving the carbides is taking over 2000F, which places that in that range. It isnt over 2%, otherwise it would be a crumbled mess right now. -

First Crucible Steel Run, and Forging.

DanielC replied to DanielC's topic in Smelting, Melting, Foundry, and Casting

That last puck gave me some problems, so i remelted it and started work on it today. Working the sides in to the center to make it more of a cylinder, then the start of forming into a bar. -

First Crucible Steel Run, and Forging.

DanielC replied to DanielC's topic in Smelting, Melting, Foundry, and Casting

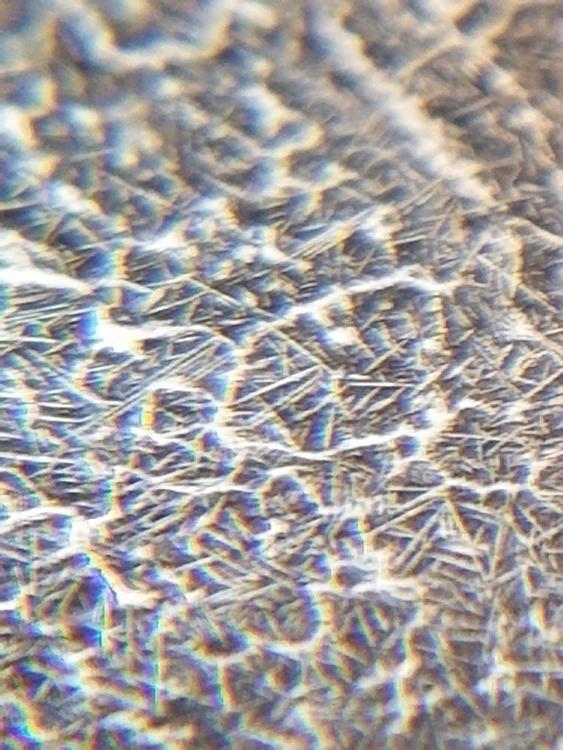

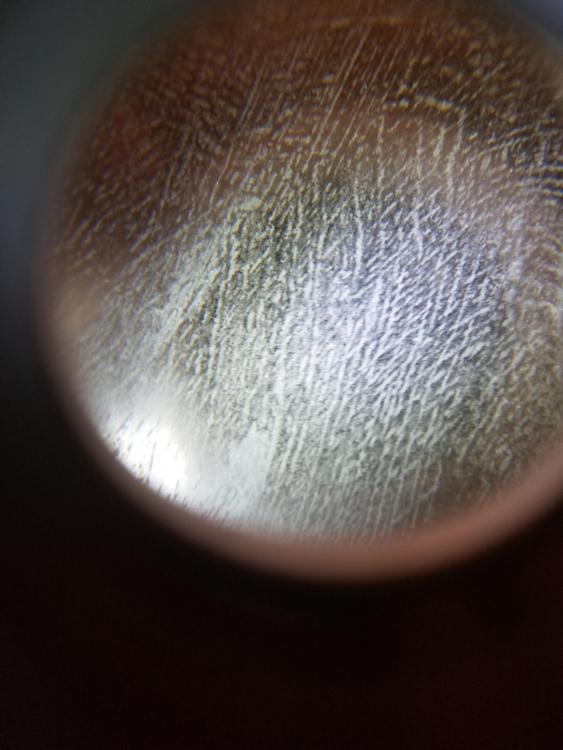

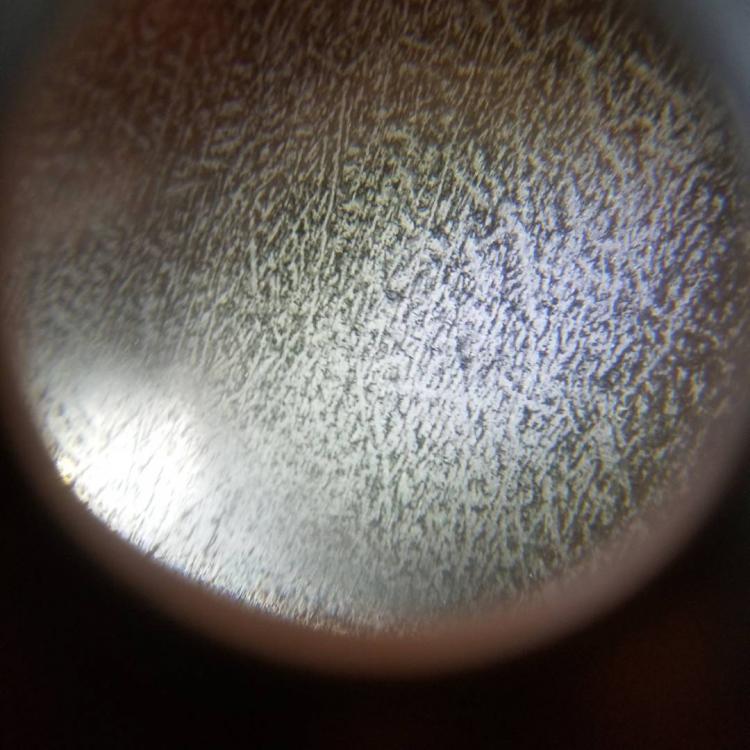

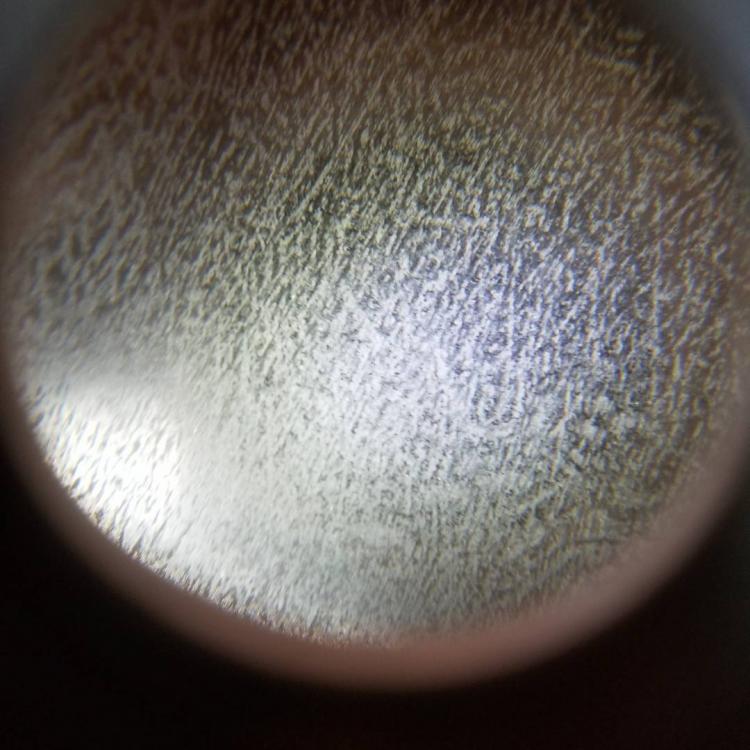

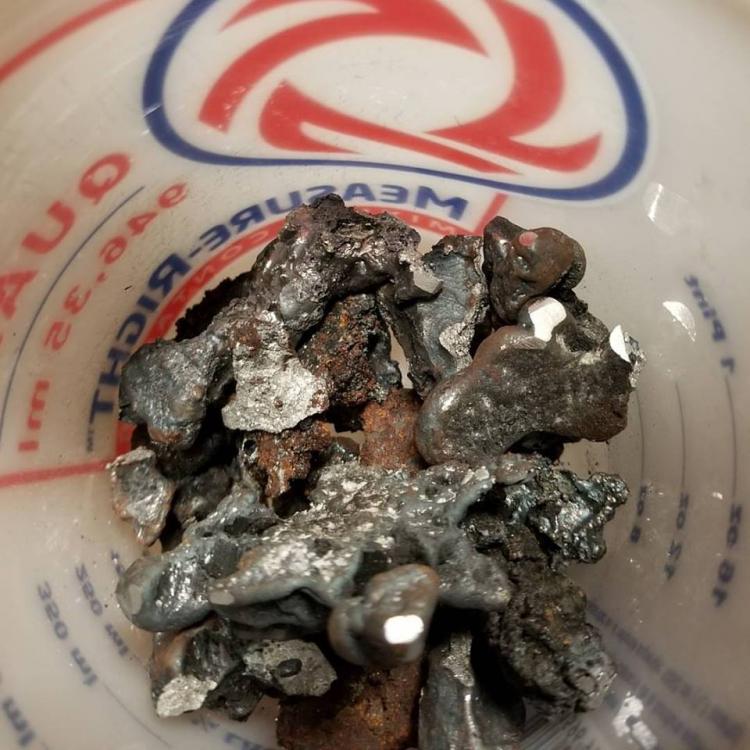

Cementite formation from the slow cooling of the steel ingot as it solidified after being molten. Around 25% by weight of both ingots is pure cementite, or iron carbide. The object is to both work the steel without destroying it, and manipulating the pattern using different levels of heat and hammering. Depending on the carbon level you produced, the working range to hammer the ingot can be a hundred degrees to around 600 degrees. My goal was to make Ultra high carbon steel in the 1.5-1.8% carbon range. -

First Crucible Steel Run, and Forging.

DanielC replied to DanielC's topic in Smelting, Melting, Foundry, and Casting

-

First Crucible Steel Run, and Forging.

DanielC replied to DanielC's topic in Smelting, Melting, Foundry, and Casting

As a further study on crucible steel, i set the first billet aside and progressed in making a new puck, larger and with knowledge gained since the first. -

First Crucible Steel Run, and Forging.

DanielC replied to DanielC's topic in Smelting, Melting, Foundry, and Casting

My Fined structure. Apparently i did things right. It matches other slides from other crucible steel samplrs i have seen at similar zoom. -

First Crucible Steel Run, and Forging.

DanielC replied to DanielC's topic in Smelting, Melting, Foundry, and Casting

Haha. I would wager this bar is worth ~$500 -

First Crucible Steel Run, and Forging.

DanielC replied to DanielC's topic in Smelting, Melting, Foundry, and Casting

Well its in billet thickness now. I hate that yhe crack made the divot, otherwise this would have been a chef knife. I will have to think about it. Maybe do another melt on friday, and work maybe a 3# puck with all of the knowledge i gained from this. -

First Crucible Steel Run, and Forging.

DanielC replied to DanielC's topic in Smelting, Melting, Foundry, and Casting

I forged out the bar at estimated correct temps to dissolve the dendritic tree and given my estimate on carbon, this took place at temps between 1800-1875F, and then final forged the last 15-20% in much lower temps, which typically ran 1400F down to about 1200F. Aside from a tiny crack on one side that i kept chasing should have been ground out much earlier, it held together with my estimations. It dissolved the dendritic tree, but due to my lack of knowledge and experience, i didnt realize i needed to dissolve the cemantite to begin with. Starting those heats are better for the beginning, rather than half way through. This way i can steer the newly formed structures into the direction of drawing and replicate that ancient damascus pattern (hopefully). Next time. -

First Crucible Steel Run, and Forging.

DanielC replied to DanielC's topic in Smelting, Melting, Foundry, and Casting

Did i mention i was just winging it here? Lol. -

First Crucible Steel Run, and Forging.

DanielC replied to DanielC's topic in Smelting, Melting, Foundry, and Casting

Thanks. Spoke to some of my German pals that do this regularly, and was shown in the phase diagram that i need to get this around 1800-1850F to dissolve the cementite that you see in the dendritic structure and start forming the iconic wootz waves going in the direction of forging. -

First Crucible Steel Run, and Forging.

DanielC replied to DanielC's topic in Smelting, Melting, Foundry, and Casting

I went ahead with confidence and took on the rest of the puck. I found it fun, even if time consuming. Normally when I am forging it is always in a run because I am forge welding, and then drawing out sanmai as quickly as possible, so this was a huge change from the norm. Firstly I thermal cycled several times before I hit the puck in hopes of created a decarb skin that can assist in holding this extremely high carbon puck together. Then lots of small hits to make it into a bar. Unfortunately that is all I had time to do today, but I assure you it was 2 hours of my time, lol. Very clean corners btw. Was verrrrry careful on heat control. Then did a quick polish to see whats going on. A lot of work needs to be done to break down the dendritic tree and make it into more of a watery flow. -

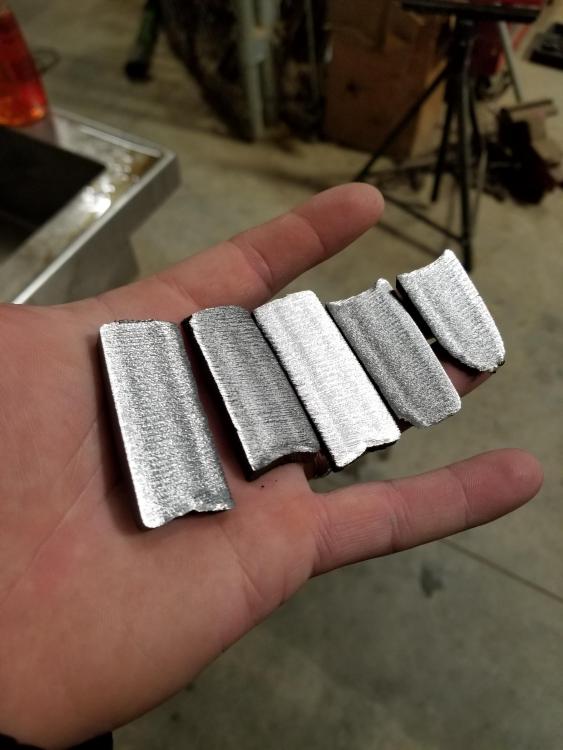

First run I have ever done making crucible steel. Firstly I want to add that I am very adept in the hearth refining process, or orishigane. At this point I pretty much make material between 1.3-1.8%C out of anything from bloom iron to crane cable. Well I have been doing a lot of studying in the realms of breaking this orishigane cold to get an inspection of the grain, and see if any colors pop out. Typically this causes many pieces to break off, smaller than I typically feel like dealing with. Having a surplus of this jewel steel, and I decided to breathe a new life in these collected piece by melting them in a crucible. These pieces range from 1.3-1.7%C for the most part. I didnt throw in anything over 2% C. A spark shows the average piece going in, which is a steel and spark devoid of Mn. Loading up the crucible with orishigane and 100 year old bottle of green glass. So 800g of feed material (steel) and 100g of green glass in an open crucible. Then placed in the quickly thrown together kiln powered by a 1" Trex burner. After it becomes completely molten, I kill the reaction and let it slowly cool in the furnace over night. The next morning I am greeted with this beautiful puck after I chip out the glass. After looking at it all day, I decided to further my study and cut a slice in the crucible steel appx 75% into it, and then with a hammer struck the streel to break what was still attached to expose the grain. The spark and the grain are indicative of a carbon range between 1.6-1.8%C. I then polished the surface of the sliver and etched to show the dendritic formation. In this picture I have two different types of steel with similar carbon contents. The one on the left was made in the orishigane process and the one on the right is this sliver of crucible steel, so I kind of had an idea of how it would feel under the hammer, even if both are worked at wildly different temps. After this short deliberation I finally bit the bullet and chewed into this small sliver in the forge. Initially I was going to hand hammer, but my 50# Murray is really an extension of my arm. I feel completely comfortable working anything under the hammer. If I feel comfortable working crucible steel under it, then I can anything. So I did. This still must be worked at within a temp window, of medium red to medium orange. Too hot and it crumbles like cheese. Too cold and it cracks. Hit it too hard, and it cracks, so it is a challenge, but one I was willing to try. So in it went. This is a Don Fogg style welding forge, and it likes to have material with handles welded on in it. This wasnt going to do, so I used some old leaf spring as a table. I didnt run the forge over 5psi the entire 2 hours of forging that was required to make a bar. So I eventually made a bar, after 2 hours of forging. After that I polished an end and etched. Also, after over 50 heats, the spark is still indicative of carbon that is way up there. More to come later.

-

Nazel 4b finally made it.

DanielC replied to DanielC's topic in Power Hammers, Treadle Hammers, Olivers

I did also get 2" of Baltic Birch ply from Larry as well for the frame, and i think there is a piece cut for the anvil as well, which kinda negates the rot thing, but apparently baltic birch ply is the snuff. -

Nazel 4b finally made it.

DanielC replied to DanielC's topic in Power Hammers, Treadle Hammers, Olivers

I think around 6" or more. The problem with wood is that it eventually rots, which requires the entire frame and then anvil to be lifted to be replaced. -

Nazel 4b finally made it.

DanielC replied to DanielC's topic in Power Hammers, Treadle Hammers, Olivers

I mispoke again. Lit says 7k anvil and 11,000# frame. -

Nazel 4b finally made it.

DanielC replied to DanielC's topic in Power Hammers, Treadle Hammers, Olivers

No, and i mispoke, they are rated to be 6,000#, but the forum wont let me edit. The truck driver told me the whole package weighed over 18,000 pounds -

Nazel 4b finally made it.

DanielC replied to DanielC's topic in Power Hammers, Treadle Hammers, Olivers

Yea its like 6-7 sq. ft worth -

Nazel 4b finally made it.

DanielC replied to DanielC's topic in Power Hammers, Treadle Hammers, Olivers

Fabreeka for the anvil, and an original oiler to the Nazel that i found sitting infront of the drive gear on the frame. It was covered in oil and grime. -

How big of a hammer

DanielC replied to Millennial Blacksmith's topic in Power Hammers, Treadle Hammers, Olivers

I think this video illustrates the beauty of self-contained, Massey Clearspace 5cwt for example -

Nazel 4b finally made it.

DanielC replied to DanielC's topic in Power Hammers, Treadle Hammers, Olivers

Indeed. It will be a monster for tooling. Larry gave me the tool holder that wraps around the die for it. Since it will be sitting for awhile, i really want to fabricate some quick changing kiss blocks like Phil uses under his 5cwt Massey.