-

Posts

2,405 -

Joined

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by jeremy k

-

-

-

David R -

Where did you get the leather to replace the old? And what thickness did you use? I have a large bellows the same size where the wood is in perfect shape but mice have attack the leather badly. I would like to rebuild mine for a 10ft x 10ft shop (ceiling mounted near the portable forge inside).

-Jeremy

-

Practice is the only way.

The first picture you posted, the first think I noticed was the fractures at the point of where you started the transition of square to round - definitely a break point if used.

Sharp corners on and anvil or anvil shaped object will/or can cause this - this is why a radiused corner is preferred on an edge of the anvil, or one can use the horn with a rounding hammer to create the same smooth transition.

Keep at it and show your results. :-)

-

Those are wall hangers to remind you where you were when you first started them, now make many more and you'll get better, then you can compare them and see your progress.

Keep it up - it'll you'll get there.

-

Forget the prichel hole, punch from one side 3/4's the way thu, then on the other side in the same heat, - take your time a bit - cool your punch in the slack tub - even let a few drops of water hit the sweet spot your punching, locate your sweet spot, then with one quick firm hit shear the slug. The problem ppl have is trying to shear the slug out when its to hot - hence the roll-over of the slug edges and the chasing it back and forth thru the cross section, let it cool a bit so it shears. Practice is key.

I use flat ended punches.

-

On 6/13/2019 at 7:29 PM, Frosty said:

I want a cell with a rotary dial.

Frosty - don't fret - there are rotary dial apps for cell phones you can download!!!

-

Renaissance wax.

-

You have the basic form needed, now it's just some practice with it to get a feel for using it with hot steel.

The shoulders on the leaf are also controlled during the spreading of the leaf - that is were more practice come into play, so you can get the metal to move where you want it.

-

Pictures (multiple views) would be a great help to see what your experiencing.

-

Mark Krause comes to mind of someone very familiar with those types of power hammers also.

-

Use only hose that is rate for propane.

-

I understand your concern with the wool concerns from the manufacturer, but I'm sure you wont get far with them as far as your end of that issue - repair and ridgidize as per your needs - I still think the cushioned support of the body will solve that mechanical damage from the over the road vibrations(If this is what is causing some damage to the interior) Otherwise I would believe the deterioration of the liner is just normal user usage, and that is normal consumable results of any forge.

-

The forge body could be set on a cushion type mount, so direct vibration from the road stops before getting to the forge - could be with some rubber mounts mounted down away from heat effected area.

-

Charles - re-lining is no big deal - burner mount - is it just mounted with just 2 threaded bolts welded to the forge body(is that what keeps failing?) - no problem weld on support to help hold the gas line end, which will be more stable during traveling down the road to your clients. To much offset weight is hanging off the 2 mounts - a support is all that would be needed.

-

Just wondering if this would be a noticable difference vs. the way thousands of blacksmith already have had there gassers plumbed.

-

Thank you for the pictures.

-

Picture of the pattern being talked about?

-

2 or 3?

-

Jason - looking good - did you drill out the pin holes and put oversized pins in to take up the wear. When I poured new bearings on my 100LG, I set up a mini scaffolding so it was lots more comfortable working than on just a ladder.

I've always wanted a 250LG, should have jumped on the couple I could have over the years.

-

On 3/23/2019 at 9:23 PM, JHCC said:

On the other hand, this 110-ton beastie is on sale for a mere $31,999!

You would probably be pressed to get a good forging speed out of that.

-

Why not have him search pics of what he wants and build from that picture?

Don't forget to post pictures of your finished product.

-

You could point the anvil towards the forge, but it all depends on what side of the anvil your standing on. A couple of quick steps and your adjusted to use it the other way.

-

Thomas - you mean trying to get to the root of the original posting?

-

3 hours ago, Meridianfrost said:

You may have the money to simply pay any price for any machine

I don't think Frosty was in any way implying that at all - just stating a fact that the makers sometimes have no choice but to raise prices to cover their costs.

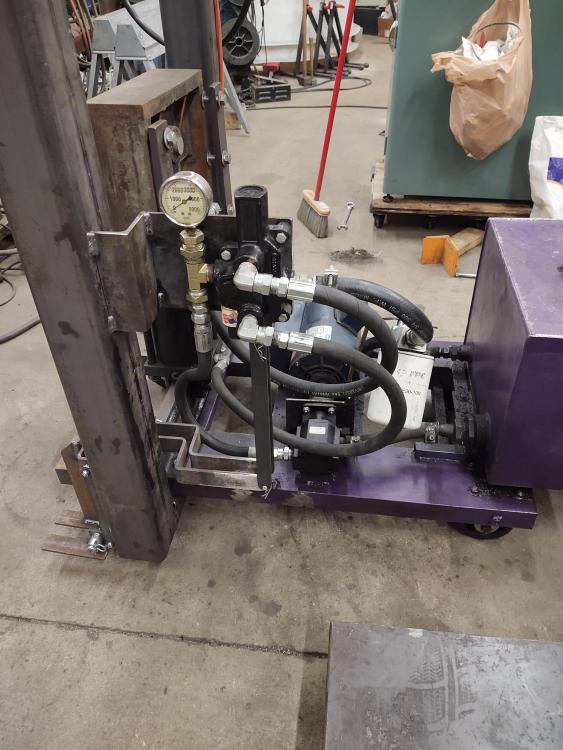

Meridianfrost - it really is like Frosty said "do you need one or just want one" - that is a business decision only you can make. If you are even remotely thinking you can improve your business with a press - then by all means you should step up and do it. Your right - not everyone has the cash on hand to invest but again that is a business decision that has to be made and only you can determine if it will fit your needs. Granted everyone would like a superb low price deal, but sometimes cheapest is not always best, as if you were to purchase a press right now - how fast could you make up the difference being you have the press and can do more work and or different work than before? - Again your choice, as your the only one who knows all your details of your clientele/wants or needs.

I got into a press not even for forge welding, and I've used it for more than you can imagine just because it was sitting there waiting to get used. Good Luck with your decision - if at least - keep doing the forge welding by hand (as so many do without a press) and keep saving up for a quality press of your choice.

New forge refrractory

in Insulation and Refractories

Posted

One thing people have to remember, not everyone has the ability to have their phone or computer glued to their fingers to respond as every question is posted. People have lives besides the Internet.

Your post is not even 24 hours old, some people check sites daily,weekly or even as long as monthly, so be patient - after all your asking for free advice, don't expect everyone to drop everything to respond minutes after your posts.

Whether hobby or professional, sometimes responses take a bit. For instance it's a national holiday here....deer hunting, most are out hunting and enjoying electronicless peacefulness.