-

Posts

332 -

Joined

-

Last visited

Profile Information

-

Gender

Not Telling

-

Location

Vancouver, B.C. Canada.

Converted

-

Location

Langley B.C., Canada

-

Occupation

fabricator

Recent Profile Visitors

-

Jackhammer for forging?

NeatGuy replied to Austin Ferraiuolo's topic in Power Hammers, Treadle Hammers, Olivers

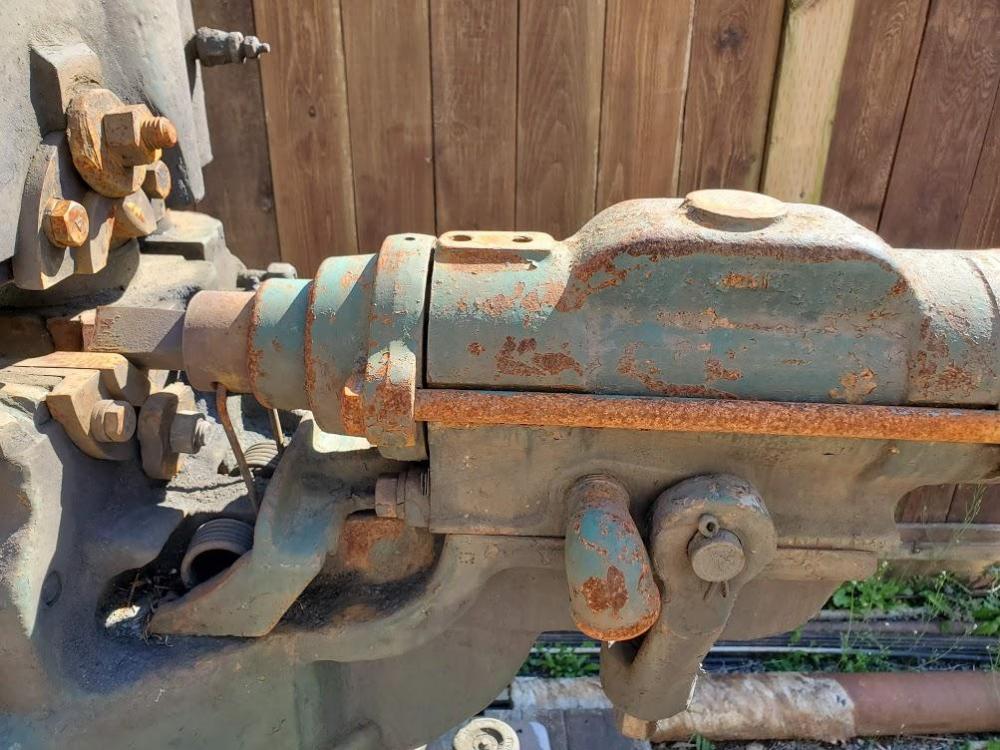

Actually pneumatic upsetters are more or less a jackhammer with an extended stroke. This is an IR34 with square head bolt dies. It will forge about 1 1/2 or so. The IR40 will forge over 2" using the same method. -

On it's way to the scrap yard.

NeatGuy replied to NeatGuy's topic in Blacksmithing, General Discussion

I preferred to scrap it rather than listen to the endless litany of stupid platitudes about how much they are worth. $1500 was not over the top. -

On it's way to the scrap yard.

NeatGuy replied to NeatGuy's topic in Blacksmithing, General Discussion

I didn't want to trade, and they were for sale for the better part of a year. -

After trying to find a home for my last IR40 pneumatic upsetterm I am done looking at it and it is on a new journey to the scrap yard, along with a LG power hammer and some misc blacksmith junk.

-

I have such a machine for sale if you are still interested. It comes complete with some dies and two heads.

-

"That’s not entirely true. If you want to go into rivet production that would be great but for a few here and there are alternatives mentioned all over IFI. " - It does not just make rivets. I watched some dude make a rivet on youtube in about five heats. I would rather buy them than waste time doing that. I suppose it would be ok if you had one rivet to make but how often do you need just one?

-

If you want to make rivets you need an upsetting machine and a pneumatic rivet gun and bucking to set them. I can make a five gallon bucket of 1" rivets in about twenty minutes (Assuming they are all cut to size first).

-

I use platens every day and there is not substitute for a real platen, they are flat, heavy, and very versatile. They are worth every penny, buy 6x8 if you can find them, square holes are best but round holes seem to be more robust. Put leveling feet on the legs so you can work with a level. I am hopping to get another 4 in the next 2 years.

- 20 replies

-

- platen table

- table

-

(and 2 more)

Tagged with:

-

I use a small devilbiss oxygen generator attached to venturi forge burner. The oxygen generator does not supply enough o2 to run a rosebud or the burner directly but it does augment the supply of o2 entering the burner. It does not get as hot as a rosebud but it is hotter than the burner without it and is definitely more economical. brad

-

Shaw & Justice dead stroke power hammer

NeatGuy replied to Happy Hammerer's topic in Power Hammers, Treadle Hammers, Olivers

Here is a scan of Scientific American I own. '> brad- 13 replies

-

- Power hammer

- rebuild

-

(and 4 more)

Tagged with:

-

hmmm my profile has my location but it does not show below my avatar.

-

Thanks Jim: I already have a platen in my shop and could not be with out it, but these 4 will go to my place of work. I would like to see your hydraulic ram setup for the platens. I have tried to get the motor and the line shaft but the were two difficult to get safely. brad

-

To me this is a very historic site but there seems to little call for the ship building industry so like many people before them they have sold to a developer. The owner does value the history so he allowed me to collect all these tools. There are NO new tools on this site. They still used the steam engine to drag the barges into dry dock up to a year ago. The photographic opportunities are great. The employees room in the oakum shed had calender and pinups the earliest I could find was from 1952. All the helmets and work boots etc were hanging on the walls waiting for the men to return. Here are some more pics of some the equipment in place: brad

-

I had a chance to acquire the tools from the blacksmith shop from a loacal ship yard. The owner told me that it had not been used since the sixties and could not remember the last time some one opened the doors. His family has owned the shipyard since 1923. I ended up with the following: 150# (I think) Dupont power hammer. a 6 in leg vice. a 200+# anvil. 4 - 5'x5' platen tables. an Ingersol Rand IR34 upsetting machine with about 50 dies. 11 - pneumatic riveting hammers and dies. a 14" shaper vice for my shaper. a pile of tongs. two large hydraulic power packs. several buckets of 3/4, 7/8 1" and 1 1/8" rivets. There is also an endless supply of wrought iron chain. Does anyone have know what the upsetting machine would be worth? brad

-

wow ... Nice job modeling that with Autocad. That would be a task to model with Solidworks so I can not imagine how long that would take with Autocad. brad