-

Posts

863 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by TheoRockNazz

-

lol, on point

-

Just got that 9gag joke... lol

-

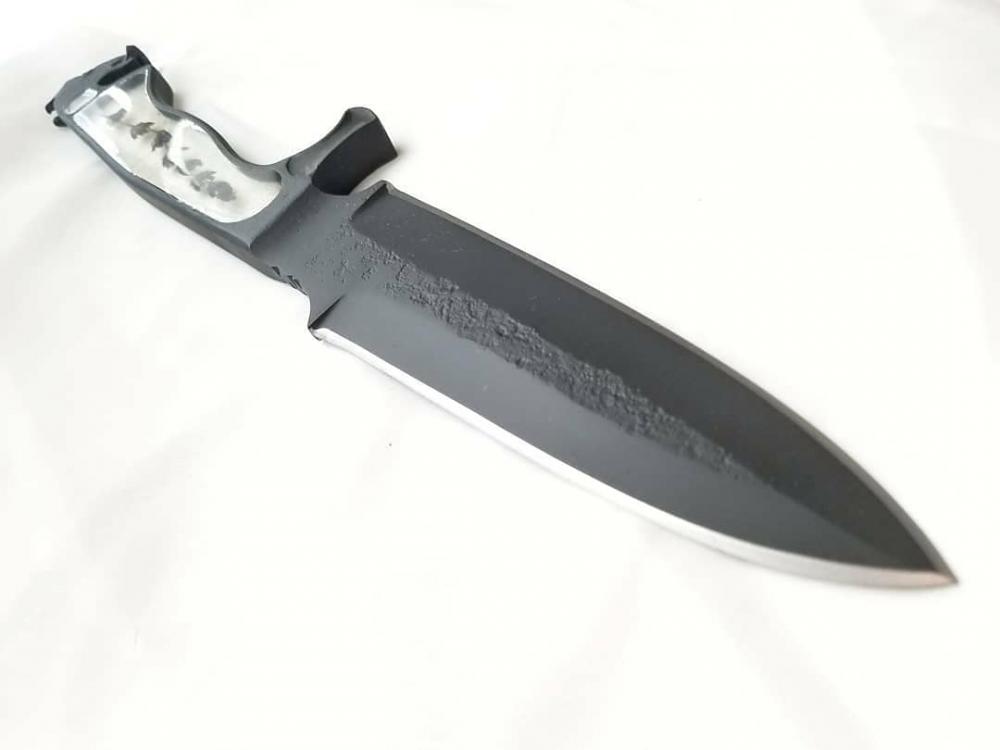

He forged the modified type XVIIIb blade in 80CrV2, and the guard & pommel from mild steel. The handle is leather wrapped walnut, then everything was blackened. Did I mention he's only 15?! I am thinking a fun Forged In Fire episode would be just my four best students going head to head because they are getting daaaarn good.

-

Coffin handle Sheffield Bowie in damascus with hamon

TheoRockNazz replied to TheoRockNazz's topic in Knife Making

Thanks guys! The pattern was supposed to be a modified basketweave where each repeat was kind of like a blocky spiral... didn't work but still fun! The medallion actually acts to round off the handle and fill the palm of the hand. The edges are all softer than they look. It's actually quite comfy... despite the fact it's probably rarely going to be used... the sad part of art knives I suppose -

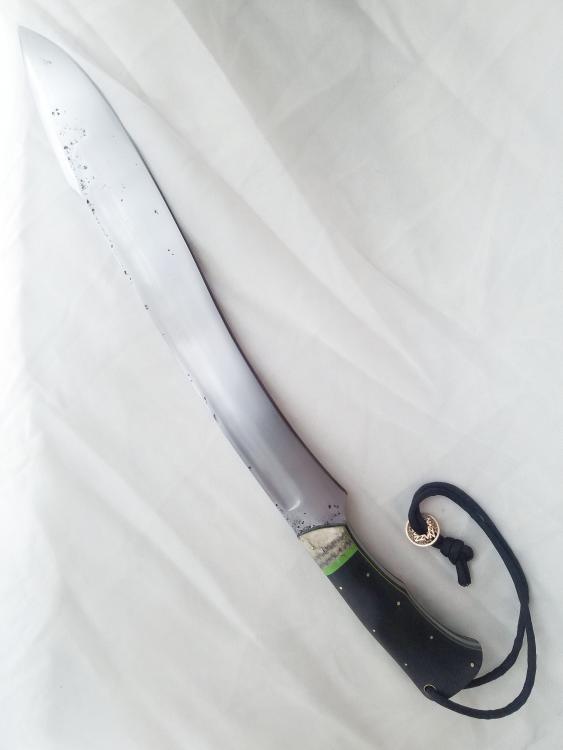

I put this knife together pretty fast out of two fun side projects/experiments that ended up working out together. The cast bronze guard was the big sister to my nuts-n-bolts canister damascus from before, and the damascus a pattern experiment. The pattern didn't turn out as planned, but it's still a lot of fun (especially if you throw a hamon over it). Handle is stabilized burl with cast brass medallion and pins. Comments and critique always welcome, Theo

-

-

Welcome to the wonderful world of knifemaking! Many kind and skilled bladesmiths have contributed to the pinned posts and classes, it's the best place to start. You'll find a lot of the first-timer questions have been answered there, but if you need further clarification or examples always feel free to post. Theo

-

It's still blade heavy, all the fittings are 3D printed and cast in bronze, so I make them as thin-walled as I can, they just look hefty

-

lol, thank you. I'm only 27, got some growing up to do myself

-

Thanks guys! And correction, blade length is 29.5"... not sure where 38 came from lol corrected OP

-

...Need I say more? lol Forged W2 blade differentially hardened with clay to form a hamon. Blade is 29.5", handle is 12". Cast bronze fittings with brass menuki (sporting my maker's mark). Tsuba was designed and cast by fellow Brooklynite and metalworker Kirsten Cosgrove. Tsuka (handle) and saya are solid black G10 as per customer's request. This sword was commissioned by a big fella for use in tatami cutting... so it's going to really be put to the test! Only slightly nerve wracking. The customer had a limited budget, so the blade only has a satin finish. The G10 saya weighs so much and is so dense you could stop a sword then pommel your opponent to death with it haha. Comment and critique always welcome, Theo

-

Cable Damascus Bowie, With a Hammon?

TheoRockNazz replied to jmccustomknives's topic in Knife Making

Absolutely, that was my second purchase after an angle grinder -

Cable Damascus Bowie, With a Hammon?

TheoRockNazz replied to jmccustomknives's topic in Knife Making

Wow man, your work keeps getting even better, nicely done. Bet your dog is eyeing that handle like "mmm, tasty" lol My only critique is spend a lil time cleaning up the plunges. -

Two more window knives and a kukri with book micarta

TheoRockNazz replied to TheoRockNazz's topic in Knife Making

Thanks guys! -

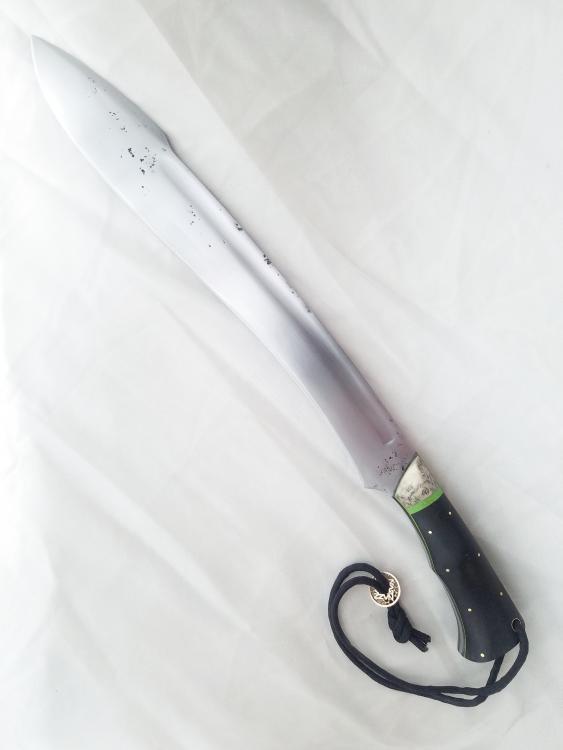

Having a ton of fun with these window knives. Both are waterjet then forged 5160 spring steel with a parkerized finish. The fighting knife has a sharks tooth in the handle with a bit of blue dye, encased in resin. The ram's head knife has doll house sweets. Here is a commissioned kukri forged in 80CrV2 with book micarta, reconstone, G10, and brass. The book micarta is something I came up with - in this case it's Stephan King's "Mr. Mercedes". You can still see where the lines of text were.

-

Parkerized integral 5160 blade with forged blade and head, handle "window" contains dried wild lavender. This knife will be raffled at the upcoming NOVA Maker's Faire @makerfairenova

-

Printed in wax then cast in bronze. Thanks guys!

-

Tanto & Kogatana Set prototype complete! This design has been in the work for some time - I've been fixated on knife sets for months. This tanto comes with it's own small utility knife called a Kogatana, typically found on katana. Blades are 80CrV2 with hamons. The sheath and scales are black linen micarta. Fittings are cast bronze. Blades are secured with magnets in the sheath. This tanto will be available as part of a limited production run I'm doing soon; people would have the choice of 80CrV2 or S35VN stainless, and any color linen micarta. Input and critique always appreciated. VID_26330815_134402_214.mp4

-

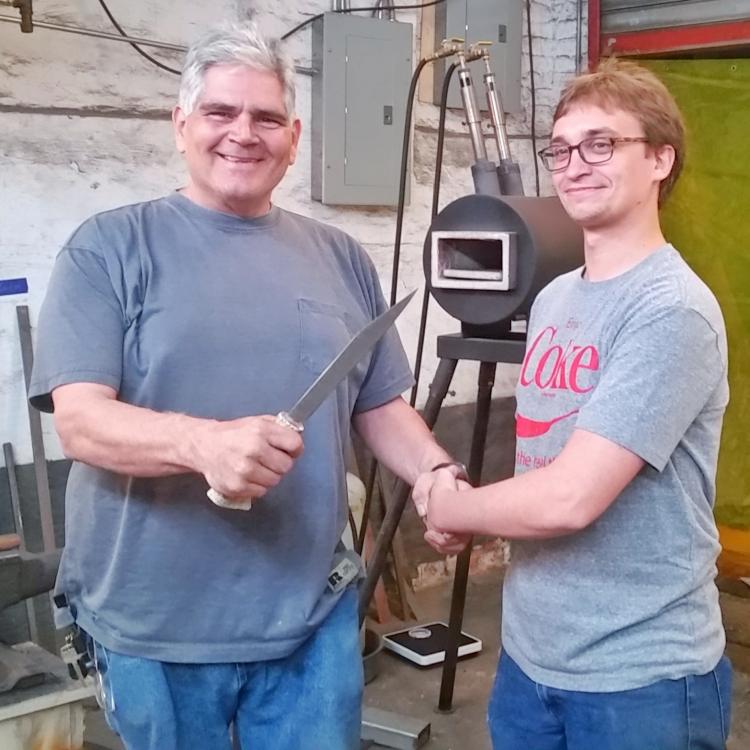

What can I write that those grins don't say already Teaching has been the most rewarding thing I've ever done

-

Very clean, please keep going

-

I couldn't find a list anywhere, so I guess one is forming here: https://www.reddit.com/r/knives/comments/7oe6yd/list_of_us_and_international_knife_shows/ Leme know what's missing!!! I want small/local stuff too

-

First blades of the new year! ... or more like finished in the new year. These personal projects took waaaay to long to complete. Forged 80CrV2 blades with parkerized finish. The integral handles feature a small window with baby's breath flowers surrounded in glow-in-the-dark pigment so you don't loose track of the blades in the dark. Scales are dyed and stabilized elder box burl with brass pins. Comes with matching leather sheath by bladesmith Justin Kirck

-

... or would it be a slipper? This project was heavily influenced by the customer's aesthetics - working together we flushed out this unique design that really spoke to him. Forged and parkerized 80CrV2 blade with 3D printed and cast brass guard and medallion. Handle is dyed and stabilized elder box burl with a black G10 spacer. Leather sheath by bladesmith Justin Kirck. This took me way to long to finish, I gotta stop dragging my feet on commissions haha

-

Fantastic work! Big fan of any forged integral elements

-

A few of my recent attempts (Photo Heavy)

TheoRockNazz replied to HEAP of JEEP's topic in Knife Making

Fantastic work, that bowie kicks butt!

.thumb.jpg.7964506c9314b812cef04c1f3b4a6421.jpg)

.thumb.jpg.e432d3341d105fe3b62ca4e1b210476c.jpg)