-

Posts

859 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Ridgewayforge

-

Your last post brought some clarity to my mind; You're not so much asking if its possible, but what the pros and cons of a spring steel hammer. Spring steel is medium carbon, if I am remembering correctly. In my opinion, and it is no more than that, I think you should try it. My experience with spring is that if you eave it normalized it can deform under heavy use (mostly struck tools). A spring hammer could be very useful for many applications. It won't be as soft as a mild hammer, but it won't be harder than your anvil face, I reckon. I think at this point its clear that not many people on IFI are interested in making a spring steel hammer. But YOU are. So? Show us. I for one would very much like to see your attempts, be they failure or success, because no matter what, if you have commited to doing this, then you have gotten up out of your armchair and into the shop. And while it might not be everything, those first steps count for a lot. Give it a try!

-

Sounds like you already answered your question. You have an anvil- It is 160 lbs, and it has a serial number of 182436. Its a Hay Budden. There are hundreds of posts on IFI telling the merits of each anvil brand. I'll preempt what might be coming: What is worth is dependent of location, market value, and quality of the anvil. Use it in good health, and good luck smithing!

-

Material 1" thick question

Ridgewayforge replied to remist17's topic in Axes, Hatchets, Hawks, Choppers, etc

you can also try and hacksaw or split the stock for your blade- now you have 1/2" x 1" stock. -

If you turn it up on edge, you'll get more mass under the hammer, and bedding it down on a stand with some silicone caulk should kill the ring. Its a real anvil! Way to go- good job!

-

I would say handmade. The imperfect dome on the bolt and the tail on the square nut are what make me say so- its done by a professional, no doubt..

-

Extending the "depth" of an anvil

Ridgewayforge replied to Andrew Leigh's topic in Anvils, Swage Blocks, and Mandrels

Now now, we don't want anyone to throw any punches- sure they make slugs, but if you catch my drift, I just don't want anyone upset! -

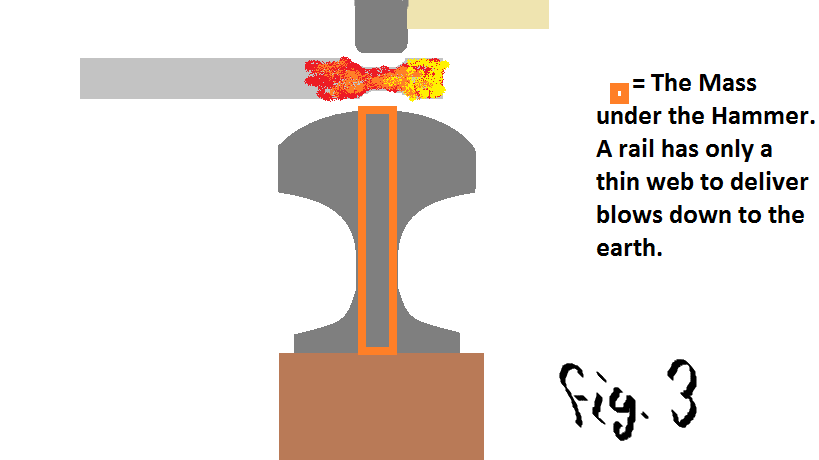

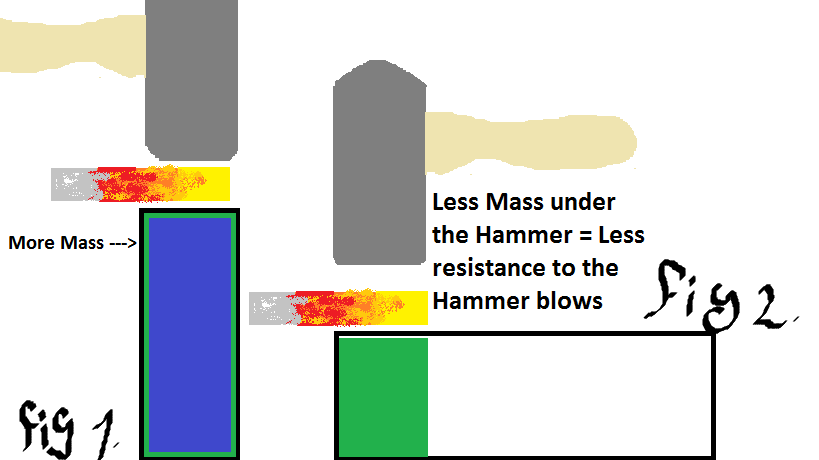

I think you might be misinterpreting what Charles Stevens is saying. Look at how his rail anvil is oriented. Not like a train would run on it. You need it to be connected with the ground, with the most mass possible under what you are hammering. If you have a 25 mm square post, about waist height- That is better than a 3 meter rail mounted on the saw horse that you have in the first picture.

-

Ausfire, Instead of making the gumnut the candle cup itself, what about three of them arranged with blank space in between, so that they are like a tripod candle base? Then you could curl a leaf underneath them as a drip pan. Maybe that would be nice?

-

This looks like a nifty way to do it- You could weld a tube down to strengthen the hardy hole, and then use the thin hollow tail to work on thin forks and things.

-

Braided cable Steel Damascus

Ridgewayforge replied to Matty Smash's topic in Blacksmithing, General Discussion

Won't be too long or too much reading until another new smith says this about you. You've got the right attitude and you'll go far! -

That face is fine. Beat some hot steel on it, and then make a smooth block to put in the hardy hole for final finishing of the workpiece. Its a start, and meanwhile, look to upgrade. But don't discount it as an anvil.

-

A Swage Block is a cast iron block with many shapes, depressions or holes in it, used to form hot metal. Its not used for forging, but for things like punching holes, setting shoulders on hardy tools, bending stock, dishing sheet metal to make ladles and spoons. If you don't have an anvil yet, don't bother getting a swage block. It is cast iron, so shouldn't be used for general forging. What do you have in your shop already?

-

Its a start. Vulcans are generally considered the low end of the real anvils, but its better than a rock.

-

What did you do in the shop today?

Ridgewayforge replied to Mark Ling's topic in Blacksmithing, General Discussion

Somehow, that adds to the beauty of the creation. Well done, and I look forward to seeing more flowers. Candle Holders I could never quite get the hang of, but I only barely delved into them before I had to pack up the shop. -

What did you do in the shop today?

Ridgewayforge replied to Mark Ling's topic in Blacksmithing, General Discussion

Wow! You're not called Iron Poet for nothing. Those are some excellent flower candle holders/snuffers. I really like how you improvised on a theme. -

This describes in rudimentary figures why you want a plate on end, so that More Mass is Under the Hammer. It is the same principle as to why it is easier to draw out rather than to upset. Fig. 3 shows why a rail stood the way a train would run on it isn't ideal. I realize that these drawing are simple, but they might help understand the concepts of why Mass under the Hammer is GOOD! It sounds like you are doing fine. Blacksmithing is Big Rock (anvil) Little Rock on Sticks (Hammer) and Fire, and Metal.

-

Andrew good to have you! This is the website that is a goldmine of information on Forging! Hopefully you will get a chance to read through and see whats already been answered, and good luck to you!

-

Extending the "depth" of an anvil

Ridgewayforge replied to Andrew Leigh's topic in Anvils, Swage Blocks, and Mandrels

Honestly, if I had the choice, I would build a wooden stand for the 6x6" and use that, and then also mount the 4" round bar upright to use as a secondary anvil. I don't know how much length you have of that, but if you have more than 20", I say use the whole thing. The more cohesive mass under your hammer, the better. If you have a very long piece of 4" round, why not bury part of it, and concrete it into the ground to keep it from wiggling? Then you can have two anvils for different purposes. Related, I have often wondered about making an axle anvil, with the top of it domed to the same circumference as a good rounding hammer, and using those two together to draw out stock more effeciently. Perhaps one day! -

Without giving us more information as to your location and things avaliable to you, its hard for us to help you- The rail anvil is better if it is stood upright, so that the most mass is under the hammer- and as to a hammer, why do you need a cutlers or dog-faced hammer? If your area is so starved for tools that you cannot find one that you want, you can at least start with a claw hammer- Its not the best, but at this point I think the best thing to do is to make do with what you can find until you can improve things.

-

They must have, since they have gaping plot holes, mostly. The plot is usually about blowing things up... which usually happens in the last 30 minutes anyways........ oh shoot, there goes my analogy!

-

That's excellent! Highly recommend become a part of any group, and learning from people in person. Sounds like you're going to do well, just take it slow and steady, and don't rush the learning to get to the 'exciting' parts- that's like skipping to the last 30 minutes of an action movie- You'll see explosions, sure, but you'll miss any plot that happened in the movie. Learning the basics is the gateway to having the ability to do any process.

-

Braided cable Steel Damascus

Ridgewayforge replied to Matty Smash's topic in Blacksmithing, General Discussion

Welcome aboard, Matty- sounds like you've done a bit of reading already. I encourage you to get a lunch and a cool brew and read through all of the stickies (pinned at the top of each subsection.) You'll learn a lot, especially in knifemaking, safety (and learn that one first, especially galvanized safety,) You'll be amazed at twhat you can learn from this website. Its best to go slow- Blacksmithing is a bit like baking. Better to start learning a simple bread recipe before diving into a complicated cake- Learn to get the basic proceses down- bending, twisting, drawing out, upsetting, and then learn forge welding with two pieces of known steel. Do it again 10 or 20 times, then try a single cable. Try etching. Then move on from there. Better to learn the basics at the beginning then try to go back and find the holes in your knowledge. Glad to have you, and good luck! -

Hi, bumpy. I recommend reading here: I Forge Iron might be the safest bet on finding accurate information on blacksmithing and other metal-related themes on the internet. They debunk a lot of myths in every post, such as drinking milk after metal fume inhalation. Glad to have you here, and hopefully you can get set up in no time to be forging hot steel like so many! Best tool on the internet is IFI- best tool we have is an open mind. After 5 years of reading this website, I'm learning still, and hopefully progressing little by little. So, stick around, have an open ear and have fun!

-

Are there any farms nearby? You can use an axle- mount it upright, as long as the face of the axle is bigger than the hammer. And you can find hammers in any tool or hardware store. Japanese hammers and anvils are simple. Just find a block of steel for the anvil. For the hammer, punch a hole at one end of the stock, and then handle it and dress the face. Don't make things too complicated for yourself. Blacksmithing is simple. We are trying to help you in any way possible. I did some searches on kijiji, and found a few anvils for good prices; 40kg for 150Euros. Are you able to drive, or train to other locations to buy anvils? Without knowing where you are in Italy, it can be tougher to help you find a suitable anvil or tools

-

Forge weld with big daddy whisperer

Ridgewayforge replied to horse's topic in Blacksmithing, General Discussion

Is it a non-possibility to build a solid-fueled forge for this purpose?