Elemental Metal Creations

Members-

Posts

412 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Elemental Metal Creations

-

It followed me home

Elemental Metal Creations replied to Glenn's topic in Blacksmithing, General Discussion

The wife wanted to stop at the local flea market saturday and I made out like a bandit! I bought a small air compressor for $20 and she bought me a 14" DeWalt chop saw for $50! -

It followed me home

Elemental Metal Creations replied to Glenn's topic in Blacksmithing, General Discussion

Thanks. -

It followed me home

Elemental Metal Creations replied to Glenn's topic in Blacksmithing, General Discussion

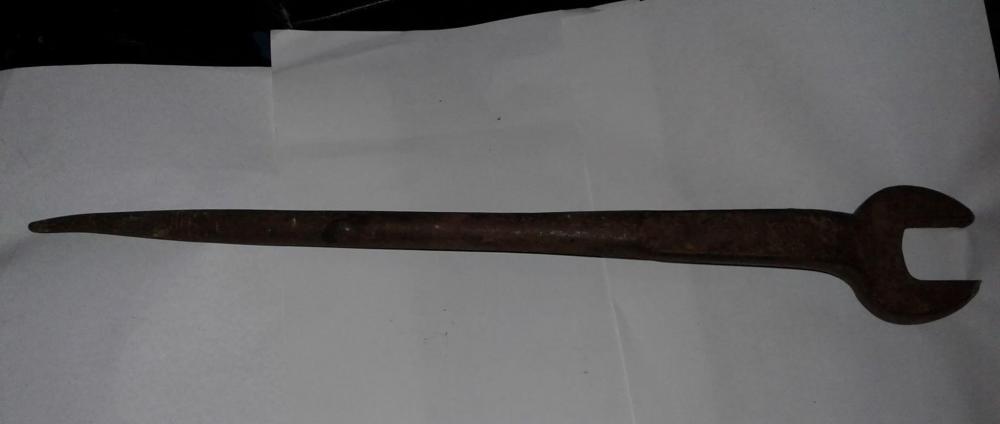

I got this at a flea market the other day for $10US. Does anyone have any info on the circle P mark? -

It followed me home

Elemental Metal Creations replied to Glenn's topic in Blacksmithing, General Discussion

The weight on H B anvils is in pounds so that is a 108 lb anvil. Fair price depends on several factors including area, how much you need/want it, condition, and how much you have to spend. If I had it at to spend I would not hesitate to pay $4 a lb for another good Hay- Budden and I don't need one, I have 2 already. -

It followed me home

Elemental Metal Creations replied to Glenn's topic in Blacksmithing, General Discussion

Frosty, I understand what you are saying and it makes total sense. I did not fully understand what IDFC was asking. I did check and the tone is consistent throughout. -

It followed me home

Elemental Metal Creations replied to Glenn's topic in Blacksmithing, General Discussion

Rebound is about 85% and the ring is LOUD. My wife heard it in the house and she usually doesn't hear either of my other anvils. Is this one with a tool steel top and wrought base? -

Show me your anvil

Elemental Metal Creations replied to Glenn's topic in Anvils, Swage Blocks, and Mandrels

Thanks. -

Show me your anvil

Elemental Metal Creations replied to Glenn's topic in Anvils, Swage Blocks, and Mandrels

My newest anvil, a 126 lb Hay-Budden SN A16845, I picked up for 400 USD yesterday. TPAAAT works! I was not even looking when I found this one. I believe the A indicates made in 1920 or later and that the top piece is cast steel and forge welded to a wrought iron base? Please correct me if I am wrong. Would some one please look it up in AIA and let me know what the mfg date? Thanks. -

It followed me home

Elemental Metal Creations replied to Glenn's topic in Blacksmithing, General Discussion

No, I also have a 75 lb Lakeshore (Montgomery Ward brand) Hay budden and a loner 300+lb unmarksd. I only had to give 400 USD tor it! -

It followed me home

Elemental Metal Creations replied to Glenn's topic in Blacksmithing, General Discussion

-

Tim Lively Washtub Forge

Elemental Metal Creations replied to Tim Lively's topic in Solid Fuel Forges

-

Tim Lively Washtub Forge

Elemental Metal Creations replied to Tim Lively's topic in Solid Fuel Forges

Tim, I made a washtub forge several months ago after my wife surprised me with your video.I use it with a champion eureka blower and love it. I make charcoal using a TLUD retort. I do have one question, just out of curiosity, what size and spacing are the holes in your pipe? -

First fire in new forge!

Elemental Metal Creations replied to Elemental Metal Creations's topic in Solid Fuel Forges

Thanks Bluerooster and Dan, The racks are sections of a heavy oven rack, on the outside the hood is just a box sticking through the wall with a 12" pipe sticking up. -

First fire in new forge!

Elemental Metal Creations replied to Elemental Metal Creations's topic in Solid Fuel Forges

Thanks Irondragon and Ramsberg. I had been wanting to build this for some time and looking for something for the base. I was scraping the dryer, stood back and looked at it and realized it was what I had been looking for. I have a total of less than $8 invested in the forge. -

Horse heads

Elemental Metal Creations replied to George N. M.'s topic in Blacksmithing, General Discussion

Funny, I was thinking about trying something like this my self Fri. -

Show me your Bottle Openers!

Elemental Metal Creations replied to Arbalist's topic in Blacksmithing, General Discussion

Thanks Frosty that was the first owl that I have made. -

Show me your Bottle Openers!

Elemental Metal Creations replied to Arbalist's topic in Blacksmithing, General Discussion

Thank you CGL, that was the third one. The first 2 never made it to openers. -

After playing with fire for about 12 years I decided to upgrade my forge. here are some pics of my custom built forge.

-

Show me your Bottle Openers!

Elemental Metal Creations replied to Arbalist's topic in Blacksmithing, General Discussion

-

Need to vent for a second

Elemental Metal Creations replied to Manno's topic in Blacksmithing, General Discussion

I made a pair of these when I started about 9 years ago. They are still one of my go to tongs -

It followed me home

Elemental Metal Creations replied to Glenn's topic in Blacksmithing, General Discussion

TP , I thought of that! Would be a challenge, the closest I have come to that is forge welding 1/2 in. cable to make a small knife. -

It followed me home

Elemental Metal Creations replied to Glenn's topic in Blacksmithing, General Discussion

A neighbor gave me a transfer case out of a truck. I took it apart to see what was inside. Not sure what I will do with the chain, thinking it will make a good hold down for the anvil. It is 1 1/2 " wide. -

It followed me home

Elemental Metal Creations replied to Glenn's topic in Blacksmithing, General Discussion

Thank you, Duckcreekforge.