-

Posts

1,227 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by SReynolds

-

Anvil ID - colonial pattern

SReynolds replied to Couchsachraga's topic in Anvils, Swage Blocks, and Mandrels

No serial no? My serial no. Must mean nothing as anvil fire didn't mention that and obviously other makes use them too and that equates the date. Did you buy the mouse hole forge book? I did make a mess with baby powder and it helped a bit but setting it under a light on anvil height stump and using a flashlight from below (and possibly above) did the trick. You gots to remember; many times one side of stamp would be much more pronounced that another. Hence we read FOR as opposed to FORGE . -

Anvil ID - colonial pattern

SReynolds replied to Couchsachraga's topic in Anvils, Swage Blocks, and Mandrels

You can search the anvil fire website info on these anvils simply by typing in mouse hole dates/ info. The date is going to be identified by the stamping. And only narrows it to a twenty year period or so. On mine, a much newer anvil, the stamping begins directly under the 1/4" thick faceplate. So it is near gone. Yours is early enough it likely isn't that far up. Mine has maybe eight lines as almost every line is composed of a separate word. -

Yep. That fan pulls in a decent 'mount of draft. The flames bend into it somewhat when on. But the tile flue pipe is so high and far from the fire pot only half the smoke and flame makes the bend. The flyash and smoke goes straight up and swirls about inside that large hood. At head level. The hood is 100% decorative. It serves only to catch the fly ash and deposit it onto my head, neck and shoulders. Thus I wear a large (4") brim hat and have installed a fly ash catcher direct above the flue tile in the form of a sheet metal shroud. It functions perfectly. No more fly ash. But still smoke at times when green coal is coaking or a student dumps coal into the coke fire etc. Normally there is minimal smoke when I'm working alone. But you want zero especially when shop is clised up in cool weather. Yes that seven inch flue tile is sort of a nozzle effect. I see that in other designs where the flames pull into a small opening and into a large box or large flue pipe. This must be same as the chimney is quite large . The fan motor isn't inside the flue. It sets outboard of flue on a shelf enclosed. Thanks for all the help. Will install the extension after the holidays. The historic village is currently closed and I don't work there in January /February. Good time to experiment further. Picture Joey drew me for the design of extension. The extension I fabricated. And the students inside shop with the recently installed fly ash hood.

-

The top pic has a light switch and ladder. The fan is inside chimney about 7' up from floor where the ladder is. Around the corner a bit from that light (fan motor) switch. Only one opening. Right at the firepot. I don't believe the flue tile is all the way up the chimney. But I don't know. The opening in the top at the bird screen is rather large so I guess not.

-

I don't see a mechanical fan in any of his. Possible there had been one. I don't know of one. I'd have to ash him. He has horizontal run and then a vertical run. Just pipe. I DO have a mechanical fan and mine won't work (draw) well at all. It is totally suboptimal. He suggested a horizontal extension to place the flue pipe CLOSER to the fire pot. So I made one. Have yet to install that.if it does work, all the other suggestions I have received over the years will go out the window such as; open a window. Raise the height of the chimney. Remove the rain cap. Build a larger capacity chimney. Not one suggestion to move the flue pipe closer to the forge fire. It may be just that simple....................

-

Horizontal run? The youtube videos by Joey Van der Steeg. I have read time and time again on this forum that horizontal runs slow the draft. If that were actually the case, why does his horizontal draft flue pipe operate so well? I mean, you really need to watch the video. I guess what I'm saying to the folks who say no 90° bends; you are obviously more than wrong.I'm not, in anyway picking a fight. When you watch his (many many videos) you will now be perplexed cuz you read somewhere no 90° bends and now you be....."oh, i guess what I read is incorrect" Joey will be more than happy to point out that the law of physics is the same anywhere on this globe.

-

Champion 40 blower -- small oil drain hole?

SReynolds replied to Quench.'s topic in Bellows, Blowers

That piece pictured above? You may have stated this, but if I missed it or didn't understand you, that is the pipe the blower clamps onto. OK you knew that. But that piece is fastened to the underside of the forge. So, no. Your blower has no stand. Cuz it affixes itself onto that pipe UNDER THE FORGE. -

Champion 40 blower -- small oil drain hole?

SReynolds replied to Quench.'s topic in Bellows, Blowers

Sorry. I don't own nor use one. I have the same or similar gear box on a different blower and no. There is no plugging hole. -

What can you make....?

SReynolds replied to Ridgewayforge's topic in Blacksmithing, General Discussion

Jimmy Jimmy Page. Rock On From what I see in my area, teachers/instructors do not want students playing guitar. They drill drill drill drill them into frustration with learning/memorizing notes on the fret board. NO PLAYING OF SONGS !!! Many a student I have spoken to relay the same message. No Songs!! Just notes. They don't learn how to play. Why I'm self taught. With playing of chords. Same is true for myself as a blacksmith instructor for a historic village. I have, for years covered terms, tooling,fire maintenance and iron/steel. The folks fell asleep. No joke. Now I jump right into striking lessons/hammer control to which they make an S Hook. Nail. Hot Dog Fork etc.etc.etc. Then I stop that and have them set down for some book learning, terminology, tooling, steel ID and etc. etc. -

Heat time for custom built forge

SReynolds replied to Deep Forest Tinker's topic in Solid Fuel Forges

http://www.azom.com/article.aspx?ArticleID=6229 -

I'm gonn tell you the truth. I have only taken apart and assembled five of these. I cannot tell you what I had for breakfast, my friend. I do not have one here where I'm at. I can look inside one and then, perhaps, I'd remember..............(??) You could be correct. I asked Joey but he hasn't had his coffee yet this morning. He has a video, so............He wanted you to contact him via Facebook or look for his youtube video. Joey Van der Steeg

-

Heat time for custom built forge

SReynolds replied to Deep Forest Tinker's topic in Solid Fuel Forges

no......you will have LESS gasoline by time you reach home. Why can you not photograph an Indian with his hat? -

Just got a Trenton anvil

SReynolds replied to Brad Mccaffrey's topic in Anvils, Swage Blocks, and Mandrels

I use two trenton anvils and the feet are so buggered/mishshapen and the stamping so hit & miss that you cannot read but for a number or two. One number has the letter A stamped directly over top two numbers. I have to wonder if these were made in the era prior to mandatory drug and alcohol testing. Interesting that the makers mark stamp is doubled or am I in need of glasses? -

What can you make....?

SReynolds replied to Ridgewayforge's topic in Blacksmithing, General Discussion

a RR Spike will make approx 700 3/16" shank nails at about 2-2.5" long and they work well to secure a rail, I'm sure. -

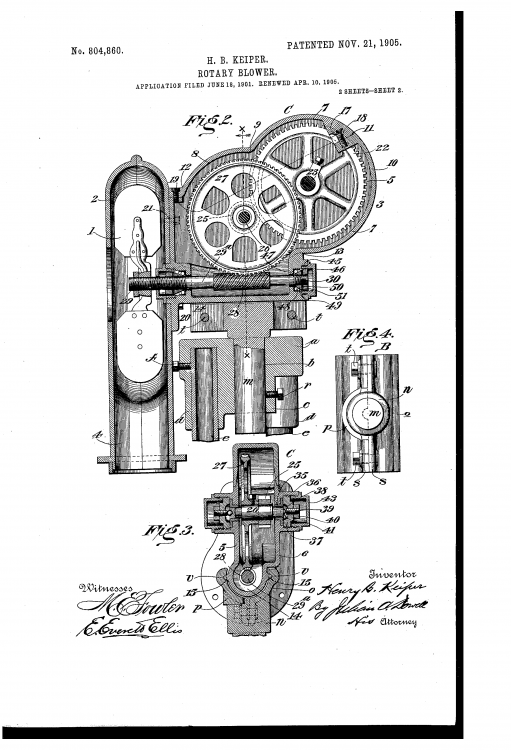

center the bronze gear to worm gear. use the threaded bushings to lock in this location. they are turned in snugly.There are lock nuts with end thrust screws to adjust the gear in place.

-

Heat time for custom built forge

SReynolds replied to Deep Forest Tinker's topic in Solid Fuel Forges

-

Well now I cannot see what you are doing so I have to assume you are doing it incorrectly. Them set screws ain't for that. You need to use the plugs. They be threaded in the bore of the case. They have two small holes in which you insert a tool to turn the plug. If I was at work I could send pictures of that assembly. Unassembled. Maybe I can wake up Joey and he can shoot you over some pics.

-

A student of mine has one. He uses it often and is so fed up and frustrated he has been looking for an actual forge. He thought he was doing ok until he used my table top forge with fire pot/clinker breaker/champion 400 blower. The advertisement says light duty and occasional use forge. I think he would be ok if it was a crank blower even w/o the table top and the fire pot. I have one as such and love it. You just gotta build up the fire deep-like by heaping up green coal (in your case charcoal) around the OD of the fire ball. W/o a fire pot it can cause you to loose interest cuz it be three inches deep and then you shove your work into that and pull it out several times. Now it is 2" deep if lucky or even less and you cuss it and try to rake it back up and you mess about and fool around and go indoors to watch Dukes of Hazard.

-

Heat time for custom built forge

SReynolds replied to Deep Forest Tinker's topic in Solid Fuel Forges

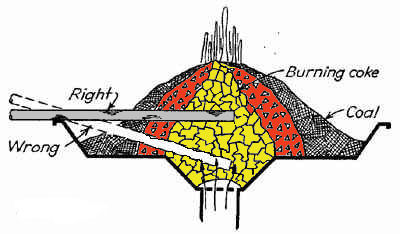

For the love of Pete , would somebody please post up the picture from this site of what a firelooks like with a steel rod in it. I have it. But it is AWOL -

My bellows looks like the picture above. But the nozzle doesn't blow into the tuyere. It blows into a horizontal pipe. Then the 90°ash dump the to the vertical pipe then the tuyere plate the fire sets on.

-

124 lbs. SS Hay Budden Anvil Clean up

SReynolds replied to Forrest Betts's topic in Anvils, Swage Blocks, and Mandrels

The idea is to avoid removal of the hardened face material. Some are made thin. Others wear thin. So any removal can harm the rebound even if it is thick. Sometimes it isnt hardened deeply. Then there is the patina. It's old. I guess it's worth something. Maybe not. That is up to the individual. This mouse hole I cleaned up was quite rusty and with a layer of paint atop the rust. I didn't fell badly about grinding off the paint and rust. The face was the same. As you can see it is very much worn and damaged. I didn't feel remorse grinding that. Nor did I see any black helicopters circling overhead from the anvil search and rescue service while doing so. It still is a severely worn and damaged anvil that bounces a ball bearing with incredible rebound. And It looks better than painted rust. My point is do whatever you like. Please don't damage a quality anvil in decent shape. I recently uploaded a pic of my abused mouse hole and striking plate I have for tasks requiring an edge. I have no problem using this anvil. My hay budden on other hand...........it's literally too nice and often times will not use it. Crazy I know. Look for a nice one and then you find you need a trashed unit too ! -

124 lbs. SS Hay Budden Anvil Clean up

SReynolds replied to Forrest Betts's topic in Anvils, Swage Blocks, and Mandrels

The idea is to avoid removal of the hardened face material. Some are made thin. Others wear thin. So any removal can harm the rebound even if it is thick. Sometimes it isnt hardened deeply. Then there is the patina. It's old. I guess it's worth something. Maybe not. That is up to the individual. This mouse hole I cleaned up was quite rusty and with a layer of paint atop the rust. I didn't fell badly about grinding off the paint and rust. The face was the same. As you can see it is very much worn and damaged. I didn't feel remorse grinding that. Nor did I see any black helicopters circling overhead from the anvil search and rescue service while doing so. It still is a severely worn and damaged anvil that bounces a ball bearing with incredible rebound. And It looks better than painted rust. My point is do whatever you like. Please don't damage a quality anvil in decent shape. -

Super easy to modify. Even make a new tuyere plate etc. for. You don't need the down draft. Cover that big hole. You adapt a hand crank blower (or electric I suppose) to the air inlet of the tuyere and you are working.

-

Favorite item to forge? Axe/hawks for me.

SReynolds replied to Dcav's topic in Blacksmithing, General Discussion

I enjoy forging hooks. All sorts of them. I especially enjoy taking an object and forging a hook from it. I may die before I finally reach the end of experimenting with hooks. They are limited only by your own imagination.