-

Posts

1,227 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by SReynolds

-

gave the trenton a vinegar bath

SReynolds replied to fireball's topic in Anvils, Swage Blocks, and Mandrels

Sure 'nough. Thanks. I will pass that along to him. I have never bought nor cleaned a heavily rusty anvil. I have had to clean them with wire wheel. I dont like paint as it chips off and exposes the light colored steel when you use the anvil. Then it gives a "fake, plastic appearance" to the anvil. I have never tried linseed oil on steel. I dont understand doing that. WD 40 evaporates and the steel rusts. The only solution I have been happy with is to clean and paint the body with matte black. Allow to dry a bit and wipe anvil body with a wrag/paint thinner to remove some paint. Leaving paint in the depressions. Then I will later oil it with engine oil. Gives a well weathered appearance. I should shoot a pic of an anvil I have prepared in such a manner. -

No kidding. I was just in Delaware too.

-

Antique Dealers too. A friend just bought a big old trenton south of columbus. There is another dealer to the north east in millersburg w/blacksmith tools etc and I found a 70 pound mounted to a stump for 200.00 just north of millersburg this spring. A friend who lives very near the Ohio Village travels all over central ohio sending me links to these auctions where they advertise antique blacksmith tools lile anvils, forges, tongs. He is retired and does strange things like that. Said the nice mouse hole snvil went for cheap. Looked good too from his picture. Well over 100 pounds.

-

gave the trenton a vinegar bath

SReynolds replied to fireball's topic in Anvils, Swage Blocks, and Mandrels

What with the stamping over/under the common TRENTON? I have never seen that. Did you wire wheel it first? A friend has one that is heavy on rust and deep pitting. Poor old thing. He would like to clean it up. So how many gallons of vinegar to cover a 155 pound Trenton............? -

Just north near Mt Eaton is an anvil dealer.....................Yoders Blacksmith Supply Fredericksburg address. You could try to see if they might sell you one (LOL) or keep in touch with the church group, local barber shop etcetcetc. There are farm auctions every sat in central ohio. Many of the involve anvils forges vises tongs by the bucket load. The there is the blacksmith show west of you in troy. You are not looking in the correct locations or empliying the wrong method.

-

Quite possibly use the two contoured blocks. The anvil will not set level. Bounces just touching it. It is way short and modified by way of two boards; two 2x8's if I remember. I'd like it hand height. Not even that as it sets now. Striking anvil level now. Serious doubt this was ever employed as a striking anvil. Or even an anvil.

-

This is gonna receive a new wooden block and properly mounted. Then oiled. I ain't touching her. Maybe hold my coffee cup. It's a show piece and don't "need" another anvil, but I'm thankful that somebody thought enough of me to care for a historical artifact. It's in good hands/safe hands. I hope to use the hardie cutter time to time and as a conversation piece. I have a chain fall to lift her from the rotten stump and place atop a fresh lumber mill find.

-

Reading about Eagle Anvil Works throws in a huge monkey wrench into conversation. Concerning ringing anvils. Their adds clearly state a solid wrought anvil will not ring and if you believe it, you were fooled. Something to that effect. Their anvil is cast gun iron alloy (steel) and don't ring.

-

150 Pound Anvil Id Help

SReynolds replied to Dylan Sawicki's topic in Anvils, Swage Blocks, and Mandrels

No good huh? Can we refer to it such as HB anvilserial no. 17887 was forged in1895 or not good either? -

150 Pound Anvil Id Help

SReynolds replied to Dylan Sawicki's topic in Anvils, Swage Blocks, and Mandrels

William Foster as pictured in the anvil book, eh? -

150 Pound Anvil Id Help

SReynolds replied to Dylan Sawicki's topic in Anvils, Swage Blocks, and Mandrels

Yummy. Nice find. A serius tool. Looks like a Mouse Hole,eh? So I'm informed that the gouged marks and divots are from a tool maker. The smith would employ the base of anvil as a test block of steel to test a freshly minted edge tool. Wrought was soft and it was right there on said anvil. -

Setting atop very rusty Trenton. There is a slot in the hardie shank/stem. When she sets in place inside hardie hole , the top is roughly at at 30° angle.

-

Some anvils I literally tie diwn quite tight. Sound of Silence. Others I use hand forged spikes to "set the anvil inplace" then employ the chain. A few wraps is plenty. I have only used a rubber mounting pad on one anvil, and it is tied down via steel (banding) straps . I have a 1/2" dia tuning fork in one anvil, held in pritchel hole. Most of them also have a large magnet under heel. Never tried silicone.

-

I was informed the fellow who donated paid 1,300.00 for her at the estate auction. Not going to argue of the matter, but this is the second HB anvil I have with nearly radius free edges. I understand many of you feel that is not proper. However as a non- collector of antiquated anvils, I have two HB's and one Trenton like that. Somebody out there using anvils feels different. FWIW; I do like my big Tenton and small Mouse anvils with very worn and radiused edges. Handy for some tasks. As if it wasn't enough; Also arriving today was my birthday gift, Anvils In America!

-

HB as if you didn't know. No. 55772 if my eyes don't deceive me. This was brought to the shop I operate and donated by a fellow collector in memory of a smith who has passed away. I understand folks do that with flags but never an anvil........so here you go. Anvil as a memorial. 209 if you want to know. And not a scratch on her. Want to load more pics but the phone isn't cooperating at the moment. Sorry The patina is just as it looks. Real deal.

-

Mission Impossible W/Pictures

SReynolds replied to SReynolds's topic in Blacksmithing, General Discussion

It is 1.5" wide flat stock. You'd have to tip it over on purpose. But no, not my design. This is a project in the blacksmith book by Lorelei Sims. But have added a drip pan to catch melting wax, as opposed to running it down onto the table of which it rests. -

Mission Impossible W/Pictures

SReynolds replied to SReynolds's topic in Blacksmithing, General Discussion

Work in progress. Needs a bit fine tuning. Another side note problem is the availability of proper sized candles. Small candles won't due in these cups. I pitty the customer who trys small candles. They will curse me. -

Mission Impossible W/Pictures

SReynolds replied to SReynolds's topic in Blacksmithing, General Discussion

Joel OF I have watched a video provided many times. I understand what you mean about locking onto the jig as well as starting the scroll on the anvil. I do use pliers such as yours for many scrolling fixtures. I will have time this week to experiment with the jig. Thanks for the video. -

Mission Impossible W/Pictures

SReynolds replied to SReynolds's topic in Blacksmithing, General Discussion

That copper piece appears to me as a drip pan. Lorelei's holder is a cup the base of candle fits into snugly. The wax will pass down candle base and fall to whatever is supporting the scroll. I want the drip pan. -

Mission Impossible W/Pictures

SReynolds replied to SReynolds's topic in Blacksmithing, General Discussion

Those are quite nice. What are the two scrolls called at the base, where it is rolled tightly? -

Mission Impossible W/Pictures

SReynolds replied to SReynolds's topic in Blacksmithing, General Discussion

Nothing is ignored, rejected nor defensive. I cannot show you what I'm making. I dont have any. The stock cannot be clamped to the jig. There is a 90° bend on it. Supposed to be there. What you see above in a picture is not what I'm making. That was demonstrating the jig isn't going to work for this project w/o modifications. This is a very complex scroll. It has a candle cup and drip pan riveted to the scroll. With a foot on the non scrolled end. There is a short 90° bend on each end. Lorelei Sims makes one. Featured in hwr book. This is similar. But I have added a rivet and a drip pan. Much more complex. The drip pan is 1/2 as thick as the flat stock scroll. When you heat the scroll, the drip pan burns away. Thus another problem to overcome. Again, hers is a candle cup only. No pan. No rivet. Simifies the work. Her cup has a small rivet forged at the base of cup. Be happy to take a picture of her project so you understand what this is. However its a scroll with a candle cup mounted at the top. But who builds candle holders which directs melted wax to run down the fixture onto the surface which it sets? Apparently Lorelei Sims. Mine will have the drip pan. This jig I modified is intended for this task. Not universal for scrolling. -

Mission Impossible W/Pictures

SReynolds replied to SReynolds's topic in Blacksmithing, General Discussion

I have not posted nor taken a picture of the desired finished product. I dont have one. Other than the units I have made in past via a bending fork atop anvil. Each end has a very short 90° bend. They are opposite one another. I tested the modified jig at home in my shop and the very short 90° bend slips directly down into the gap and is held there while I scroll the flat stock. Again, I dont employ the entire scroll. If i desire to simply scroll for a common scroll I use the any of the bending forks or one of the home- made jigs with various sized collars to achieve desired size. The purpose? There was not any viable method inwhich to secure the flat stock to the jig. -

Mission Impossible W/Pictures

SReynolds replied to SReynolds's topic in Blacksmithing, General Discussion

That is exactly what I want and desire. A crude "hook" or bend on the end. Each end. I dont have to forge it to a precise dimention to use the jig. The bend on the end slips down into the gap just fine. It isn't limited in any way. I'm making candle holders. Only half of the holder is a scroll. The other half is , well , not scrolled. -

That is what I do. Weld round stock to a hardie shank!! Love it !!!! Happy I'm not the only one who tackles tasks the easy way ! Need reins for my tongs; weld on round stock!! Gotta love it. And yes, the bottom fullers i have purchased or are in the tool collection at the national historical site are relatively short and yes, rectangular skirt ; The portion that rests atop the anvil face. That was the phrase I'm looking for! I will try another day to forge one with the "RECTANGULAR SKIRT" but need a horizontal bickern now..... I simply wanted to forge some hardie tooling as opposed to fabricate from torch/welder etc. It takes time to figure out all the steps employed in forging hardie tools. Thanks !

-

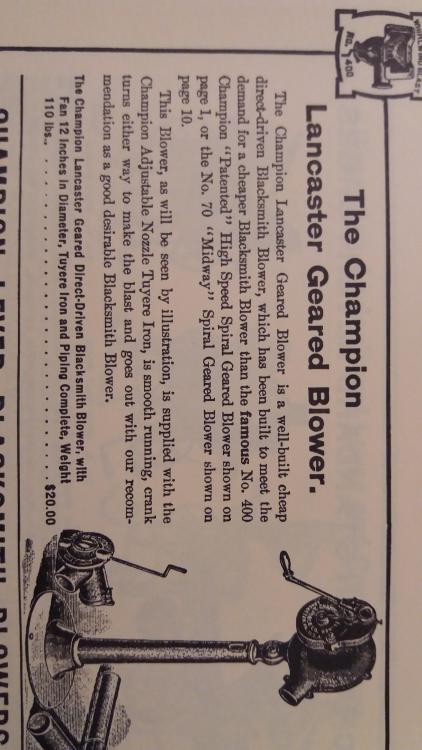

You are not looking for the Lancaster Geared No. 1 You'd think I'm quoting Obi Wan but in reality, there isn't such. You are looking for simply the Lancaster.