-

Posts

244 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by fluidsteel

-

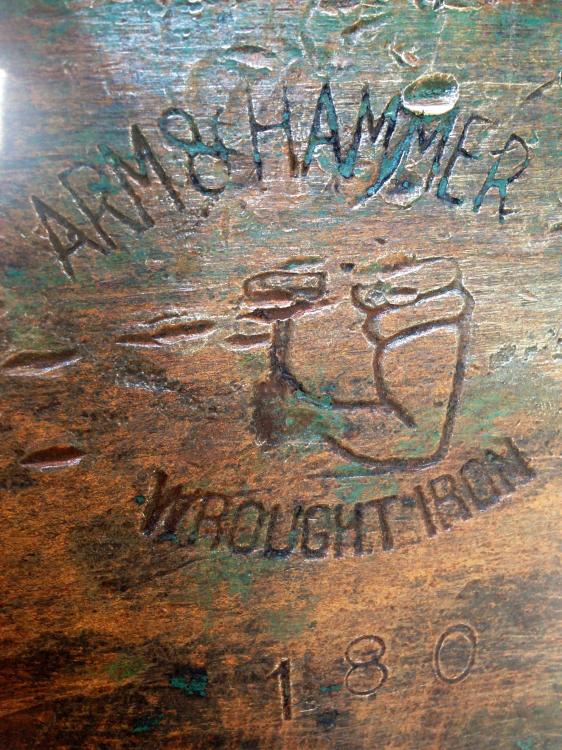

The weight is stamped under the Arm&Hammer The serial # will be on the front ledge of the feet. Use as is unless you have time to read up on the Gunter repair as was said. You only really need a flat spot the size of a hammer face. You could use a piece of forklift tine or similar if you need really flat.

-

You can by Batson's book and all that info is in it. Then it's easy to source the parts from Northern Tool or Parker etc. I can't imagine there is enough markup in a kit to make it worthwhile.

-

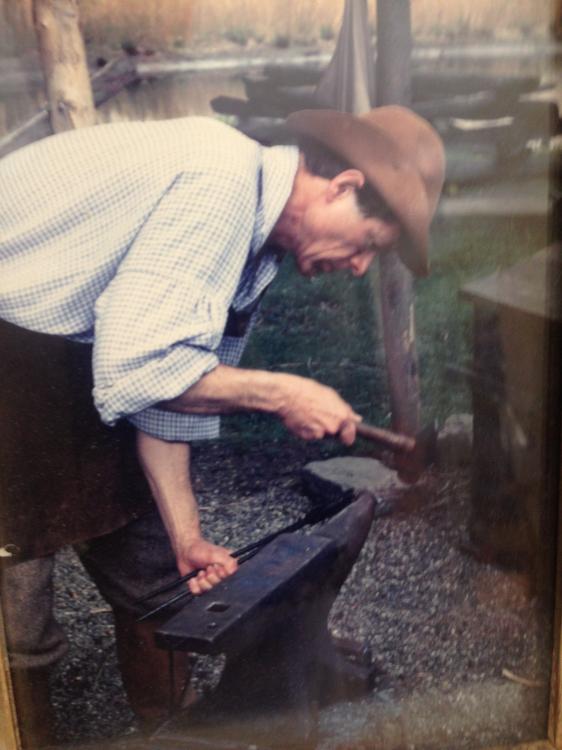

It's a 180# Arm & Hammer, 220# cast iron stand. Bought for $250 from the widow of the man shown. Originally I was just helping her sell it. Suggested $1000 for the pair and she sold it to me for $250 because she said she wanted it to go to someone who would love it like her husband did.

-

That is great. A great alternative to a stripped screw box.

-

-

Forklift Tine Anvil, Need Ideas!

fluidsteel replied to TimberTim's topic in Anvils, Swage Blocks, and Mandrels

On end -

Seeking advice on cleaning up an old anvil

fluidsteel replied to Dw Pauly's topic in Anvils, Swage Blocks, and Mandrels

I hose them off to remove loose rust and take a wire brush to it to remove loose rust then dry with paper towels. After that I spray with WD-40 and take a twisted wire cup wheel to it with my angle grinder. Rub it down with warm boiled linseed oil. -

I've long been planning a press build as I wanted a C-Frame more robust than what was available, but now that you are in the game Larry, I think I shall yield to you. If you are selling in the $4,500-5,000 range I would be handing you money.

-

When I first started forging I bought my 300# Fisher and swage block from a guy who had one of these for $100. I chose the swage over the vise and dearly regret it today. I too am green with envy. I would love one of these for forging animal heads and other tasks.

-

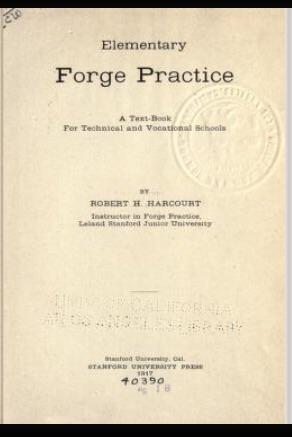

https://www.stanford.edu/about/history/ I don't understand the confusion or argumentativeness. It was named Leland Stanford Jr after Stanford's son. There wasn't a JR College and even the inside cover simply says Leland Stanford University and published by Stanford... Officially today it's still known as Leland Stanford Jr University...

-

It is from Stanford University. Not a Jr College... https://archive.org/details/elementaryforgepractice00harciala

-

They are great vises. The 6" I bought for holding stakes while raising copper dishes. The 4" will go on my lower bench in the shop to hold a knife vise so that I can swivel the knife vise around to do file work and hand sanding.

-

what do I have here?

fluidsteel replied to matei campan's topic in Anvils, Swage Blocks, and Mandrels

I had never heard about them sharing bases. I always associated the caplet shape to a Trenton. Good to know. Is that written up somewhere? I love my 180# Arm & Hammer. -

what do I have here?

fluidsteel replied to matei campan's topic in Anvils, Swage Blocks, and Mandrels

The caplet indent is indicative of a Trenton. -

Charles Parker / Parker / Chas. Parker: They are famous for the shape of the jaws on their machinist vises. The jaw shape allows for more complete access to the workpiece being clamped. Some history on the company and Charles Parker himself: "The Meriden Enterprise Center is a large manufacturing plant that is home to over 60 businesses, located in the center of Connecticut.The plant was the former home of companies such as the Charles Parker company, known for the manufacture of the Springfield rifle and the development of one of the early repeating rifles in the mid- nineteenth century. Charles Parker was born in 1809 and rose from poverty to become oneof Connecticut’s leading industrialists. He also became the city of Meriden's first mayor. He started his manufacturing career inventing and producing coffee mills in a small shop in 1832.By 1860, he owned several large factories and employed hundreds of people, in and around Meriden. Parker products included hardware and house wares, flatware, clocks, lamps, piano stools and benches, vises, coffee mills, industrial machinery, and, after 1862, guns. Guns, however, neveramounted to more than 10 percent of Parker’s business. Charles Parker died in 1901 and his descendants carried on his businesses until 1957. The Great Depression of the 1930s took its toll on the Parker enterprise and it never fully recovered. Parker products have now become “collector’s items,” especially the Parker shotguns. The Charles Parker Company sold its gun facility and the rights to the Parker gunto Remington Arms Company in 1934, and Remington continued the Parker shotgun line until World War II.The attraction by collectors to the Parker shotgun comes because of the gun’s inherent quality and beauty.The Parker gun is an American classic". Copied from the Garagejournal.com

-

Looks pretty good. I have two Chas Parkers, a 956 that is 120# and an 80# 994 swivel. It took me about 4 years to find them for a reasonable price. Found both of mine in the last month.

-

I agree with Andy. You won't make it worse taking a flap disc to it. Take it down enough that you can have an area to forge on. Just don't get overzealous on the grinding. If you grind it and it has poor rebound and dents easily then Google Robb Gunther anvil repair. There is a right and a wrong way to weld repairs on anvils.

- 14 replies

-

It says 1905 right on the side as well as farrier... Lol

-

This was from here in the Portland Oregon area. I bought my 6" vise from this bin. Almost mint condition for $160. Not a steal but a good price.

-

Expected rebound from a repaired anvil?

fluidsteel replied to Frozenforge's topic in Anvils, Swage Blocks, and Mandrels

That is a cool anvil. Looks like it probably had a couple top plate pieces fail to weld in the original forging and after they popped off it was used a lot. It would be both sad and cool to see it become what it should have been. -

I have a 150# a Fisher. That's a great size. You shall be happy.

-

I picked this up two weeks ago at a garage sale. It has 1-1/2" jaws, a 1/2" "anvil" and a working spring. It's a nicely forged little tool. Just a little smaller than my 110# 6" Peter Wright leg vise. I cannot find any info on the mfg. THB & Co or something like that. It looks German how they have a large plate on the lower half.

-

Picked this anvil up for $250 including the stand, 6 nice pairs of tongs, a cross pien hammer and 4 steak turners. A former co-worker saw it and asked the customer if she would sell it and he gave me her number after she said yes. I told her $1 a pound would be a "family" price, and that most anvils like this go from $2-4 a pound. She talked it over with her sons and decided $250 was my price. I'm looking forward to forging on it this weekend. I believe it has slightly better rebound than my 150# Fisher and equal to my 300# Fisher. Hopefully bedding it in some caulk helps the ring. I'm spoiled with my Fishers quiet thwack. Here is her husband some years back. She said he was a smith on a historical farm in New York in the sixties. She forgot the details.

-

I'd guess it's a #260 or so. My 300# Fisher measures slightly bigger. Depending on condition $1-3 a pound. $800 could be reasonable as well as $300 a deal depending on condition.