-

Posts

1,061 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Michael

-

-

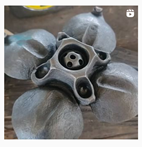

Hauled my heavy cast iron forge table and the massive cart it sits on up to Petaluma CA for the California Blacksmith Association's Spring Conference. Caleb Kullman of Santa Fe New Mexico was one of the demonstrators and the site manager asked for the forge loan for his program. A gorgeous, Yellin inspired flower rosette out of 1 1/2 stock.

Great Conference, our first in 2 years! Everyone, all 300+ was in the same good mood at the same time.

Education set up an outstanding program that was accessible to both beginners and all the smiths working on their level 3 grills over zoom for the last 2 years.

A good time was had by all.

Shouldn't take more than a few days to reassemble my forge with a couple of improvements that having it apart allows for.

-

What an incredibly instructive video! I feel like I know exactly how to do this from one watch. You're a great teacher!

Michael

-

I got an email the other day from welding inspector in town for some refinery work, looking for a place to forge during a week off. (My email is listed on the smithing group website as a board member) He wasn't able to connect with some of the local pros, but came over and be the first guest in my new shop space.

Nice guy, has a tiny smithy back in Louisiana and is connected to Gulf Coast Blacksmith Association. We did some pass through punching and drifting and wasted some 1/2 inch bar playing around in the gas forge. Shared a brew and some conversation before I steered him off to a big, monthly flea market this weekend. He's been tool hunting the local fleas that are open and Sunday's is the biggest. I know of at 3 big post vises pulled out of there.

It was also very helpful to have 2 people working in the 8x16 foot space. Wasn't sure I'd be able to have visitors in a shop this narrow, but it works.

-

Nice Trammel! Have to check out that FB group.

A friend had the first open forge saturday at their shop and I went to help out. Not enough gas in the torch for my project, putting some "Life" into a forged, multi piece figure. So I helped out some, the shop's part time welder is really a jewelry person, and wanted to make a RR spike coat hook so we talked it through, did some bends and some drilled some holes, we'll work on punching holes next time. Drawing out the shaft of the spike was going slow. Checking if they minded, I offered to do a bit of work over the horn. 'Oh, you mean really hit it! Yup.' Jeweler's work had them choked up on the hammer and tap, tap, tap. Goal was to go home with something to hang on the wall and we got there.

-

I'm getting ready to cut some 4140 dies from Cloverdale forge to fit their guillotine. 3/4 by 2, and just a bit hefty for my metal saw. Gonna use a nearby friends big Ellis to cut 45 degrees and make a butcher dies.

My arm hurts just thinking of hand forging H13 into shape for die stock.

Michael

-

11 hours ago, George N. M. said:

For top tools that aren't swung like a flatter, punch, top fuller, etc. I just jam a piece of wood in with a fiction fit. IMO it does not need to be as secure as a hammer head.

"By hammer and hand all arts do stand."

When the handle on a top tool loosens with use, you hold it vertically and slam the back end of the handle on the anvil face to tighten it up. Old hockey sticks make great top tool handles.

-

5 hours ago, ThomasPowers said:

"As he sank into the bog?"

you make that Thomas? I've been scouring my local recycling places and junk yards looking for just that sort of small footprint store display. I would guess dowels or 3 foot sections of steel at a hardware store. Most of my scrap/stock is still resident on the patio where the smithy used to be. Also keeping an eye out for some sturdy shelf brackets, or large plant hangers to mount on wall for the long stock, mostly 20 foot sticks cut in half, 5/8 and 3/4 square bar. I could forge them but shop time is limited just now and I"d rather be making stuff more interesting that shop furniture, though it needs to be done.

-

Love the barn door hardware solution for moving heavy things. Gear to keep an eye out for at swap meats and garage sales.

Thanks!

-

Friday lunch, cut up some 3/4 inch coil spring. On Saturday, used a friend's forge and hydraulic press to make rough tong blanks from the 9 inch sections of coil. Sunday made another set of mild steel bolt tongs, with some jaw alignment tips from the friend with the press (who has taught a LOT of classes) improving on the last pair. Gas forge, 10 years old, is glowing alarmingly at the top, the rusty section where the burner fits in. New gasser build is in the cards.

-

41 minutes ago, pnut said:

I found the whole set at my local library's annual spring book sale. They bought a new set to replace the old ones. I paid five bucks for all the books I could fit into a shopping bag. I got the entire Foxfire series in paperback and a few other books for ten bucks. I've read them all but there's only two I seem to go back to frequently.

Pnut

Let me guess...The Foxfire Book and Foxfire 5? Those are the two I ended up keeping.

Michael

-

Made a set of tongs yesterday. 18 years of smithing and I'd never gotten around to making a set, start to finish, from scratch. Started with 12 inches of 1/3 by 3/4 mild. Followed some printed instructions from a 2001 article in The Hammers Blow. sized for 3/8 square. Not bad

, the hang of the reins could be better, something to focus on the next pair. Took a little under 3 hours. Eventual goal is a set of spring steel tongs, quench hazards acknowledged. A friend has a set of the strongest, lightest spring steel tongs I've been envying for years now.

-

Honest shock and surprise it wasn’t taken! Been surrounded by Michaels growing up, was sure I’d have to add a # or something

Michael

-

Nice anvil, nice stand! Does that stand increase the ring over the the wood?

-

Here are images of a "Hofi Style Chimney" . Could be galvanized, could be aluminum.

I also had galvanized pipe for a chimney in the old smithy space, well ventilated but the forge stack never seemed to get hot enough to off gas the galvanized coating. It did get hot enough to melt off stickers about 2 feet up the pipe, but not higher. Anecdotal data points, but stickers are a cheap way to see how hot it's getting.

I'd be careful, keep an eye on the chimney, looking for any deterioration in it. And keep an eye out to scrounge some uncoated steel duct.

forgoing a chimney in the new smithy for now. Burning coke and lots of ventilation space in the half walled sheet metal building make a chimney seem unnecessary for now.

-

Nice work TW! I like the texturing on the petals.

Some of my archery friends, who seemed to have made enough knives, cleavers and ulus, just asked me to demonstrate a rolled russian rose.

Did a zoom call with the group a couple weeks ago, making multiple S hooks come out the same. They are branching out to "practical, useful projects"

I made a ton of these when I started out. One thing that comes to mind (and that I'm gonna try in the next few days) is to make the initial flattened section a tapered wedge shape, so the inner petals are not as tall as the outer petals. Not describing in well but the idea is the outer petals cover more of the inner rose.

Best of the pile from '06, two years into forging metal

-

-

Thanks for showing your set up. Love that style of forge. Welders will talk about 'burning 100 pounds of rod'-stick welding, or 'a spool of wire'-MIG to get a feel for what your working with and I think the same applies to managing a coal fire. Not sure what the poundage might be.

-

On 10/6/2021 at 4:13 PM, Frosty said:

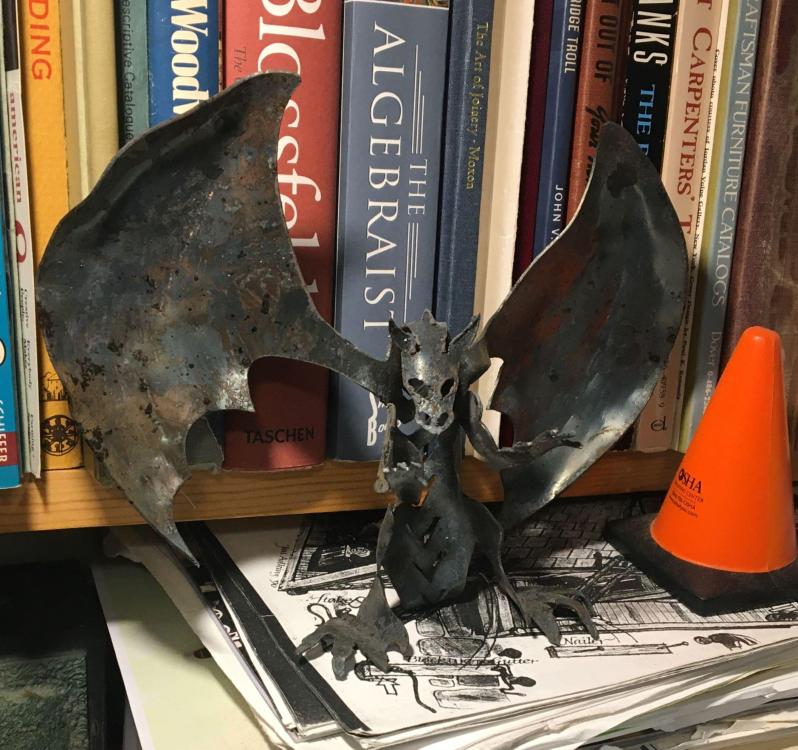

Oh

! That's pretty darned demonic Michael! I'm thinking poster material there, be a great flag over a booth at a conference.

! That's pretty darned demonic Michael! I'm thinking poster material there, be a great flag over a booth at a conference.

Frosty The Lucky.

Thanks Frosty, I'll suggest it to the smith who came up with it. CNC Plasma cut templates that are shaped hot on hollowed wooden blocks. Anna demonstrated these at Roaring Camp near Santa Cruz last August. Heating the sheet metal in a coal fire. It was a very accessible project for kids and newbies. She had a whole stack of dragon blanks and other animals. The blocks had round and elongated hollows to shape the body and the wing ribs, and went into the slack tub after each heat. The blocks are expendable over a day of making these. Great fun! I'm trying to get her to design a Balrog!

-

The hardware cloth LETS the old beer drip out so there is not a puddle at the bottom when I go to dump it out.

-

It Lives! it LIVES!!

So many buckets! working under a leaky roof will do that. And when they die, either by rust or dropping a big chunk of clinker in your favorite quench bucket, the pinhole leaks were sneaky, they do service as coal buckets, clinker buckets etc. My best beer can bucket rusted out the bottom years ago and is lined with hardware cloth, to avoid a puddle of old beer dripping from the cans.

-

Just moved into my 8 x 16 space over the holidays. An overgrown corner of the yard with an ancient Monkey Ward aluminum shed. The shed came down, the space was graded, drainage accounted for (space is in the path of runoff) and the neighbors were kind enough to repair the fence the shed was holding up!

From clearing the space to lighting the coke forge, about 6 months of hard work. The old leaky corrugated patio cover was repurposed, walls to roof, rusted out roof to walls in the new space. It's narrow, but dry save for condensation off the metal roof. Getting all my stuff in there is a challenge, the old space was a shared 12x22 feet. I think coke and propane storage will be outside the smithy, and my scrap pile needs some serious thinning and re thinking.

Gallery link above shows all the work in progress pictures.

Best,

Michael

-

Lit the first coal fire in the new smithy in the back yard! Made a bracket to connect the "building" frame to the woodworking shop next to it.

New space is 8x16 feet, tucked into a corner of the yard after some significant drainage work was put in place. The spot was/is, in the path of water flow from all the houses uphill and had to be accommodated.

Old space was a covered patio with rusted out roof panels and intact wall panels. The panels were swapped for the new space, with the walls making up a nice corrugated roof and the rusted roof making workable walls. A bit of a squeeze getting stuff in there, coal and propane tanks may need to be housed outside of the perimeter but the new space works, in the rain especially.

-

When I had a Bug in New York and the heater control cables rusted out, I'd crawl under the car in the fall, wire the heater channel valves open for the winter. Come Spring I'd crawl under the Bug again and snip the wires to close the valves for the summer.

-

Hey, I thought you said no windows?

Just kidding, looks like a nice shop. How's the 'thru the wall' coal forge flue set up.

Just kidding, looks like a nice shop. How's the 'thru the wall' coal forge flue set up.

Michael-just about to finish the walls of a new smithy

TFS Anvil vs. McLellan Anvil

in Anvils, Swage Blocks, and Mandrels

Posted

I've used the McLellen anvils before (John's shop is about 2 hours away and I buy coke there)

They are nice, a couple of friends have bought them. They are loud! the 4140 makes for a piercing ring that you will want to quiet if you are anywhere near neighbors.

My .02

Michael