-

Posts

114 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Steven NY

-

Hello All, I picked up this leg vise yesterday, I believe it is a true Indian Chief from what I have read. Light chamfer on the legs, drop forging marks. (I know everyone asks, but anyone have any idea of the date from the look of the vise?) It appears to be in really good shape but I will know more once it is cleaned up and ready to put into service. It is stamped either 100 or 110 pounds. I Think I have developed a bit of a problem, this is my fourth leg vise, I think I am addicted to them. I had originally picked this up to pass on to friend that has been looking for one, but now that I have it in my shop ... . The threads on the screw are nice and square but I have never seen the necked down area before. Any thoughts? In other news I missed a 311 pound Peter Wright anvil that looked to be in good really good shape that was sold for 600 dollars, what a difference 12 hours would have made. Have a great day, W

-

Hello Nathan, I also run a coal forge on Anthracite. I have included a picture of the way I setup my fire pot before adding the coal. Once you get your first coal fire going they will become easier to start as you will be able to use your left over partial burnt coal from your previous fire to start you next one. I light the paper under the pile of wood and as soon as the wood is going I start shoveling on the coal, starting at the front of the fire pot and working my way back until I have 3-4 inches of coal pilled on top of the still burning wood. This is the smokey stage of the operation. After the wood burns down under the coal and the coal is burning the smoke will die down to almost none. From the time I light the paper to the time my forge has a good bed of coal burning is 10 - 15 minutes. For reference my fire pot is roughly 14" square, and 4 inches deep, with a bottom blast style air supply. It take a long burning wood fire under the anthracite to get the forge going. I light an anthracite fired forge everyday, one at work every other day and one at home almost every night. What size coal are you using? Do you have a picture of your set up and how you lay your starting fire? Hope this helps, W

-

GuardedDig2 Thank you for the information, and the great picture. I have not seen that one before. I am glade to see the ideas I had about this type of blade were accurate, I will have to try making one one day. Thanks again and great work, W

-

Excellent looking knife. I have been researching this style of knife, could we get a few shorts of the edge profile. I would like to compare your knife to what I think I know about the shape of the blade. I am always on the look out for reference material. Did you put in the single sided fuller with the blade supported in a swage? I guess to put it another way would you mind sharing your techniques for forging this unique blade style? Thank you and have a good one, W

-

Great looking knife, I really like that size knife. You did a great job pulling all the little details together to make a knife shine. Have a good one, W

-

Show Me Your Antique Drill Press

Steven NY replied to Brenton's topic in Drills, Post drills, Mag drills, etc

Thank you Chris, I was really impressed once I had it mounted and tried it out how well it worked. I look at things like this old mechanical machinery and I am always impressed with the ingenuity of the people that came up with those ideas. Just a note on my restoration, the advancement and retraction knob that raises and lowers the spindle is not original. I made it out of a antique spool as mine was missing. The shape does not match the originals. Have a good one, W -

Forged in Fire hammer maker

Steven NY replied to GMoore's topic in Blacksmithing, General Discussion

GMoore, I know Ben Snure was on FiF recently and he is a hammer maker. Hope this helps, W -

Show Me Your Antique Drill Press

Steven NY replied to Brenton's topic in Drills, Post drills, Mag drills, etc

This is my Champion, I use it to counter sink holes mostly, it works a treat. I built the wood column around a jack post just so I could get it mounted and working. Have a good one, W -

Congratulations Pnut! Blacksmiths as a form of active meditation works, keep up the great work. We have never met, but I am there with ya. W

-

Mark Aspery did an article with picture detailing this process in one of the old hammer blows if you are an ABANA member if not I can try to talk you through it. Mr. Aspery made it simple and clear. I just checked and it is in the free section so anyone should be able to view it. Hammers Blow - Volume 22, #4 Fall 2014. https://abana.org/hammers-blow/# Hope this help, W My bad wrong shell type. I agree with the swage idea.

-

Hello, Maybe to much heat building up between the cast ribbon burner face and the metal shell that delivers the gas air mixture causing early ignition behind the cast ribbon burning. Simple said, gases igniting before leaving the ribbon burners face. Just my first thoughts, good luck, W

-

Punt, Yes they are, the idea being if I mess up a die or it does not do what I want I waste less steel. It also allows me to replace the striking section while maintain the dies. After thousands of hits it really takes a beating. The top section can also and is made of different steel than the dies. Have a great day, W

-

Hello, I weld on a mild steel striking surface, it keeps the top of your dies from mushrooming, and is replaceable if needs must. I also have a mild steel hammer I use for punches and chisels. So I would say either option would work. I only heat treated my butcher tool do to the the fine edge. I leave all others as forged, a few of them are just mild steel and have held up for many years. Have a good one, W

-

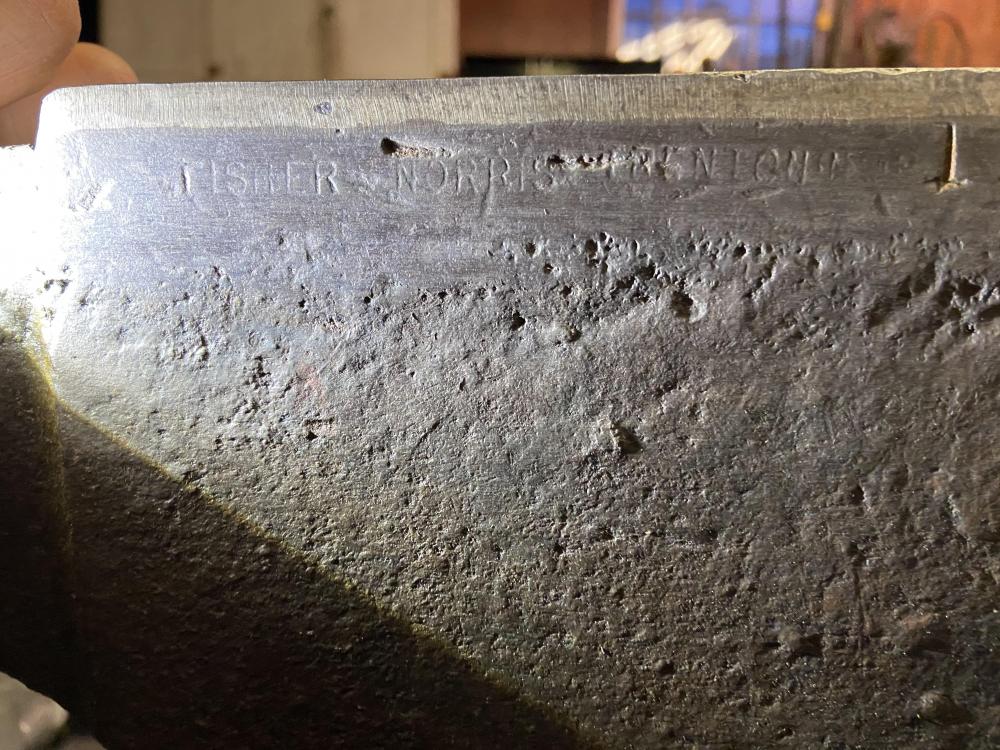

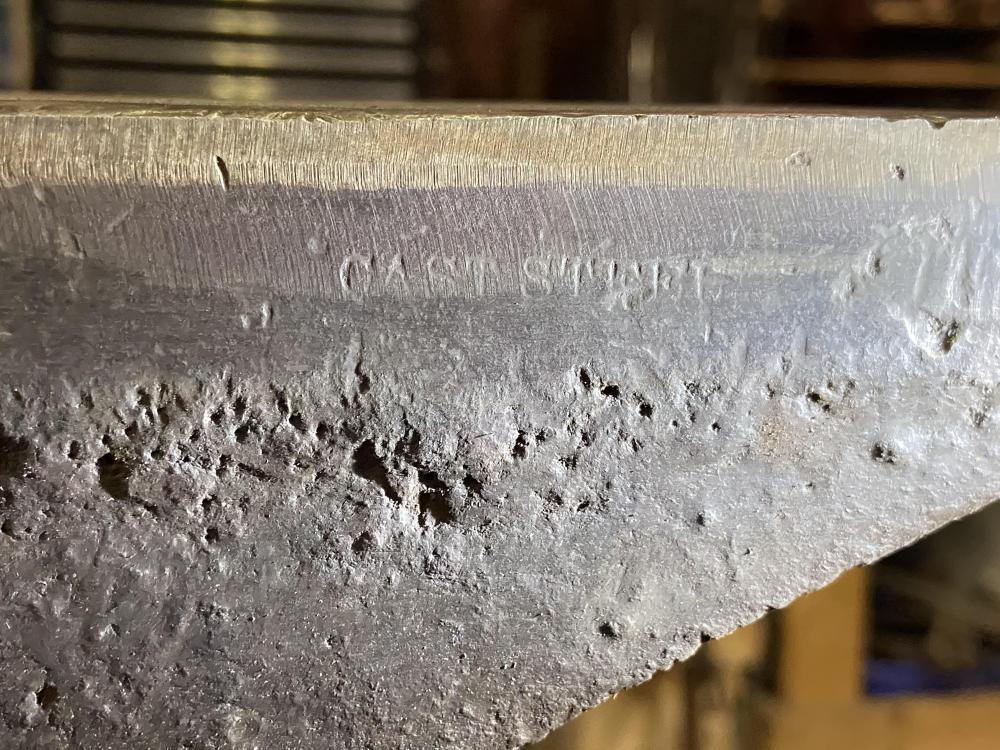

Thank you all! njanvilman : Thanks for the information, from it's condition it is hard to believe it is 140 years old, clearly it was well cared for. I will continue that tradition. I do plan to use it a little just to see how it works, but it will not be my main shop anvil. I will check the base and let everyone know if it is stamped with a date. I will also put it on a scale to check the 119 stamped on the side, maybe that is not a weight marking. Again thank you all for the kind words and information. Have a good one, W

- 658 replies

-

- Cast anvil

- Fisher & Norris

-

(and 1 more)

Tagged with:

-

Hello JLP, Sorry about that 119 pounds of fun in this little guy. As of right now I will be sticking to using my Trenton anvil. This one will be stored until it is needed. As I was taking pictures of the anvil tonight I noticed the reinforcement under the heel, that seems like a great design feature I have never noticed before. Then again this is my first Fisher. Have a great night, W

- 658 replies

-

- Cast anvil

- Fisher & Norris

-

(and 1 more)

Tagged with:

-

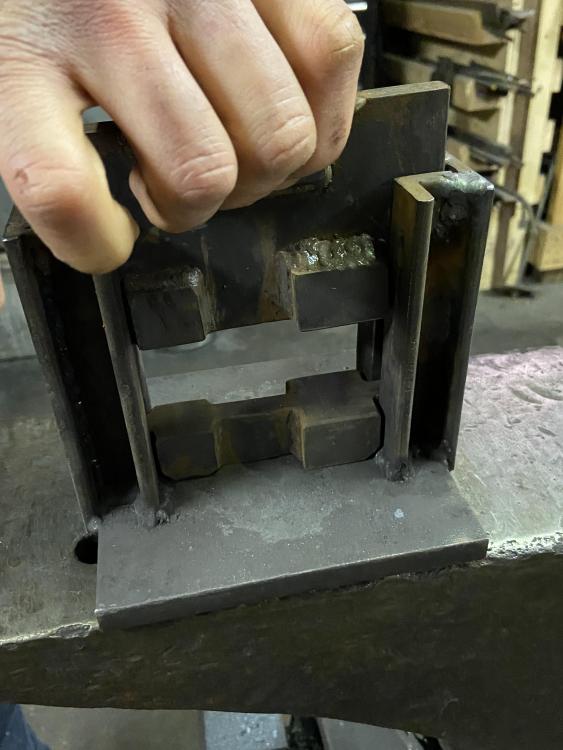

Hello All, This is my guillotine tool, I have never seen one like it before. It has worked great for me for over 10 years. I have had to re-weld a few things over the years but it has taken a heck of a beating in that time. Over the years I have added to the tooling that fit the frame. I can also just use the top tool with this design and have the metal resting on the flat plate at the bottom of the frame. Have a good one, W

-

Hello all, I picked up this beauty a few weeks ago. The gentleman I purchased it from said he could remember it in his grandfather's garage when he was 6 or 7 years old. So he has know of it for over 75 year. It has been passed down through his family, and has now come to me; along with all of the details he could remember of its history. He has no idea how or why his grandfather had it. It was not used until he did some blacksmith work with it several years ago. It is in great shape, and I am now its custodian. Any light you fisher experts out there may be able to shed on its pedigree would be greatly appreciated. Have a great night, W

- 658 replies

-

- Cast anvil

- Fisher & Norris

-

(and 1 more)

Tagged with:

-

Hello, Maybe you are trying to do too much forging in one heat changing the stocks shape to radically to quickly? Also hydraulic press dies tend to stay in contact with the stock for a longer period of time as compared to say a power hammer. Is it possible the outside of the stock is cooling down against the dies and causing the cracking because of the temperature difference between the center of the stock and the surface which is in contact with the dies? My first thoughts, hope it helps, have a great night, W

- 17 replies

-

- w1 steel

- hydraulic press

-

(and 1 more)

Tagged with:

-

TIG OR MIG the age old question help please

Steven NY replied to hobb0042's topic in Welding Equipment

Hello Hobb, I love my TIG welder. Its ability to join base metals with little or no filler material makes it more useful to me in my work. TIG welding is very similar to oxy-acetylene gas welding, melt your base metals then feed your rod and move the puddle forward. I feel TIG gives you greater heat control for all levels of base material thickness. MIG is quick and easy but almost always needs more grinding to blend the weld. With MIG your wire speed and amperage has to be in balance which always leads to a larger bead on the surface at least for me. I have found that with practice I now prefer my TIG welder for almost all of my welding needs. Just me 2 cent. Have a great day, W -

Albany, NY - Coal Source

Steven NY replied to JSD's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Hello JSD, I buy my bagged bituminous coal from: Dutchman Enterprises 95 Willett St, Fort Plain, NY 13339 They charge about $9.00 per 50 lbs. bag. I also buy anthracite coal from them (about $7.00 per bag) as I burn a mixture of both coal varieties in my forge. They are located about an hour from Albany. I started off forging with anthracite as that is what I use to heat my home and once heating season arrives I buy my coal by the loose ton and use it for both forging and heating. Have a great day, W -

They look like Cobblers Pliers to me, my dad made shoes for a living for over 30 years. He had several pairs very similar to the ones shown. They where used for lasting the uppers. Have a good one, W

-

Besides Blacksmithing I am a hardcore baker, over 1,000 loaves of bread last school year. It all started when I dropped off a few loaves of bread for a bake sale for an injured teacher. Before I knew it I was baking bread for half the school. My money from baking helps fund my blacksmithing. I did not expect to have so many people interested in the bread I was making, but my name got out there and it spread. I am now also baking for the school my wife works for. I see this as the same type of opportunity for you. It helps the students, and is good advertising for your blacksmithing. It could spread like wildfire. If you do it for the altruistic reason, then whatever comes of it will be profitable even if you just break even. Have a good one, W

-

Preparation and planning in action, with a dash of threat assessment. If only everyone would practice these things we would not need so much parenting from our government and its officials, but alas the few always spoil things for the many. Then to keep us all safe uncompromising laws are enacted. While I bristle under what I deem sometimes excessive oversight, I also can not come up with a viable third option that would work for all. It is an imperfect system but it is our system, and I hope that it is truly acting in the collective best interest with the best of intentions. I find I am happiest when I am doing my own thing in my own very small corner of the universe, making as few waves as possible. As for the thread topic, this is my first attempt at a nail header. The hole is tapered to be wider at the bottom smaller at the top. It is miss aligned with the shank and while it works I think it would work better if it was not. The shank on the bottom fits in the pritchel hole of my anvil so I do not have to chase it around the anvil or hold it while I forge the head.

-

With all the different BBQ grills, smokers, hibachis and who knows what else being allowed it seems a hot dog hung over the forge when needed might be the answer. Most people set out to use Chimenea and grills without the preparation and thought that goes into our forges. It is sad to think that common sense has become so uncommon as to cause these types of problems. Here to hoping for reasonable over site from local government officials. I have never had a problem with anyone yet, but twice have had policeman running down my driveway while I was starting my coal stove to heat my home. I always thank them for keeping an eye out. When you live in town, it does seem to always be a concern. Have a good one, W

-

Hello JLP, Thank you for the feedback, that makes sense that is is an early Trenton made in Germany. The factory it was bought from was built by stone masons contracted from Germany by our towns name sake, Alfred Dolge. It does have some edge chipping as you said the face must be very hard. I have been using it for 10+ years now and I have no complaints. You can see the hammer marks from its production, impressive piece of work. I love the anvil stand on your new Fisher, and the anvil is great too of course. I love the fact that the person that mounted it took the time to taper the stand. Have a great night, W