bw94

-

Posts

27 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by bw94

-

-

-

3-30 psi

-

Frosty, I understand what your saying by have the tip at least halfway across the air intake to start tuning, but like I said, I've tried different lengths from 1/2 to 1/4 and everywhere in between. I can't get it to run to even start tuning. I've deburred the holes after cutting them down. Maybe I need to put on the dunce cap and sit in the corner!

-

Thanks Frosty, I'll give that a try

-

I took it out of the T and tried just running the mig tip, it would run as long as I kept the flame on it, but went out when the flame is removed

-

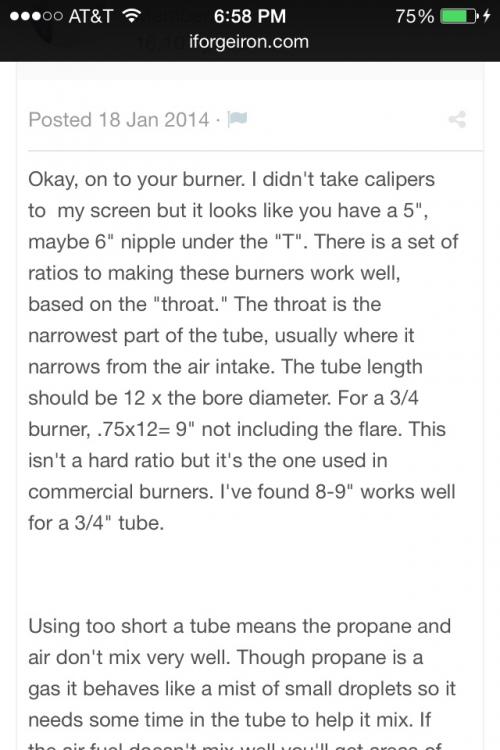

I've tried various lengths of mig tips, I've tried running without mig tip on and it'll work, I'm using .023 for the 1/2" and .035 for the 3/4", I'm thinking I may need to make the mig tip hole bigger.

-

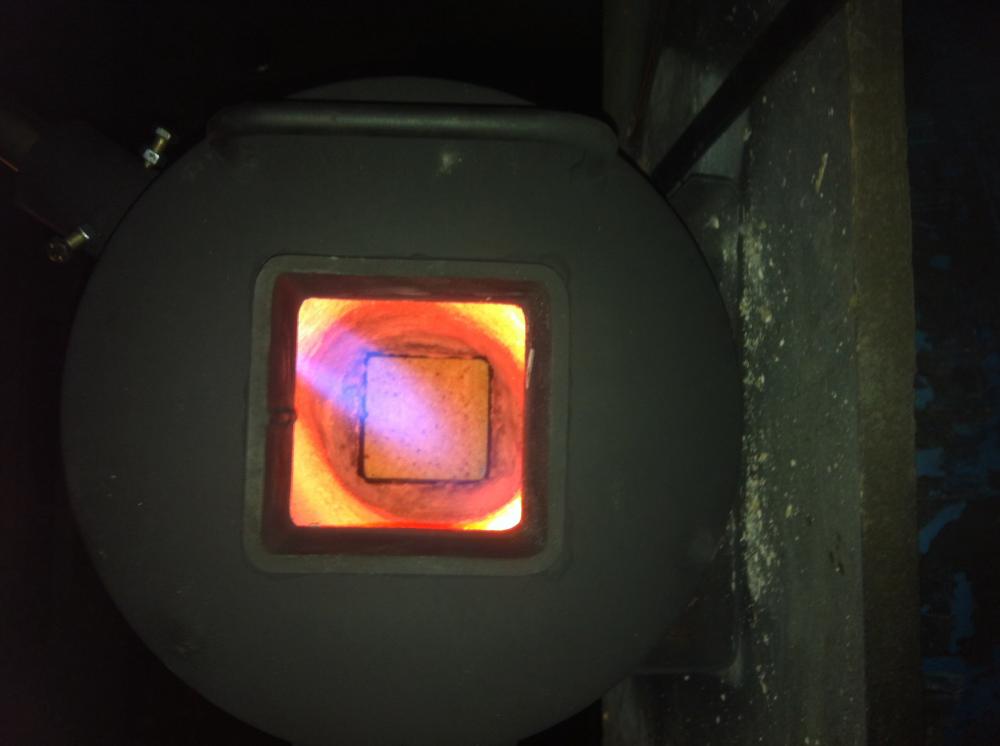

I thank all of yall for yalls wisdom and helping out the new people on this forum! I made a little progress on my forge, I cut it down the length from 18" to 14", welded on the burner holders, and built one 1/2" T burner. I've tried running in open air out side the forge and also tried running in the forge, it'll run at low psi but when I turn it up past 5 psi it goes out. I've tried different lengths of mig tips, I've cut about a 1/4" off of one, I think I may need to go a little shorter. The mig tips are .23, overall length of 1". Sorry the pictures are rotated

-

Your right Frosty, there's no need in experimenting with a proven design, I'm gonna stick with two 1/2" T burners. Sorry for the abbreviations and lack of knowledge. This is my first attempt at building a gas forge, I just want to get it right. Thanks

-

Do u think it would be ok to run 2 3/4 t burners and run them at a lower psi, or should I run 2 1/2 T burners?

-

Alright, here's my plan. I plan on cutting down the forge from 18" length to 14" and adding a 4" pass thru hole in the back of the forge for longer material. I figured out with the 2" of blanket it would take it to 6"x10, that should put me at around 300 cu", not sure if I'm gonna use 1/2" t burner or a 3/4" t burner.

-

-

What about the 3/4 t burner

-

We'll I started making the burners and I have a question about the length of the down tube, frosty says a 8"-9" works well for the 3/4 burner, I've seen pictures of others that are shorter and seem to work well, my question is what would be a good overall length for the down tube? And would I have to use a flare on the end of it? Thanks alot

-

Thanks, I'going to start find the materials to build the burners

-

Thanks frosty, so would I use a 1/2x1/2x1/2 tee if I was making a 1/2 t burner, what length would the pipe need to be?

-

A Book Gas burners for Forges, Furnaces & Kilns by Michael Porter Sold by Skipjack Press. is one good place to start. Another good place is to search this forum for Frosty T

I've purchased this book, frostys t burner look like a lot simpler design

-

I've been trying to find instructions on building one

-

Is the construction the same for the 1/2 as it is for the 3/4, same mig tips?

-

Thanks Frosty! On your t burners do u have choke plates on either side of the T

-

I figured once I add the 2" of blanket material and the firebrick for the floor it should bring the volume way down, I've seen a forge similar to mine with the burners spaced out 5 3/8" apart. I've decided on 2 3/4 burners, built right they should cover 300-350 cu inches. Should I open up the back for a passthru?

-

The way it sits now with no insulating material the volume is 1414 cubic inches(10x18") , if I account for the 2" of blanket it puts it at 6x14, with the radius of 3" and length of 14, it puts the volume at 396, doesn't sound right, so I would need 2 burners spaced about 6" apart

-

Do yall think it'll be ok to leave it the length that it is, once I put the 2" of ceramic blanket I'm gonna lose 4" in length. Should I cut a hole in the back as well?

-

I guess what I meant by general is that I want a forge that I can forge and heat treat knives but at the same time if I wanted to forge weld, I'd be able to, I'd rather have more than I need. What are common dimensions of kaowool? Frosty, I looked for your t burner, I found the post, I wasn't able to open the pics. Thanks for the replies, this is all new to me

-

Thanks! I updated my info. Do u think I should shorten it?

Trying to build a gas forge

in Gas Forges

Posted

I've let run for around 20 mins