-

Posts

48 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by Anderson G. Phillips

-

Pneumatic controls are crazy!

Anderson G. Phillips replied to AdamG's topic in Power Hammers, Treadle Hammers, Olivers

Well as long as it is working with the two valves again. The slow Creep up is most likely a small leak internal or otherwise. You could link the two mini valves together to move them at the same time, but with as loose as everything is you most likely engage them some times, then almost miss them other times. If you could find a way to remove some of that side to side slop it would make the machine a lot more consistent and easy to tune. Thanks for the video. -

Pneumatic controls are crazy!

Anderson G. Phillips replied to AdamG's topic in Power Hammers, Treadle Hammers, Olivers

I remember your first post, hate to hear you are having problems. Why are you dropping back to one mini valve? You can most likely leave the second valve plumbed in, just tie it around back. Frosty is right dried out seals and lack of oil are a good place to start. On the Big Blu if you reverse the control line on the mini valve or on the spool valve by accident it will do just as you describe. If you cant get it post pictures and re-post the diagram. We can help, Utility hammers do run off magic and fairy dust after all, you just may be doing the wrong incantation. -

Hammer heating up

Anderson G. Phillips replied to zadvorney's topic in Power Hammers, Treadle Hammers, Olivers

Just that we are always diligently looking for a better way. As it is with allot of thing though, the older simple method wins out. As of today I don't think there is a system for guiding a hammer head than brass oil and steel, at least not that will hold up and has near the value. That is all I meant. -

Hammer heating up

Anderson G. Phillips replied to zadvorney's topic in Power Hammers, Treadle Hammers, Olivers

Not only does some plastic take on different lubricants, it pretty much all will absorb metal dust over time. your Gibs get bigger and bigger over time. Brass Gibs are the way to go... for now. -

Help - input on my Kinyon hammer?

Anderson G. Phillips replied to AdamG's topic in Power Hammers, Treadle Hammers, Olivers

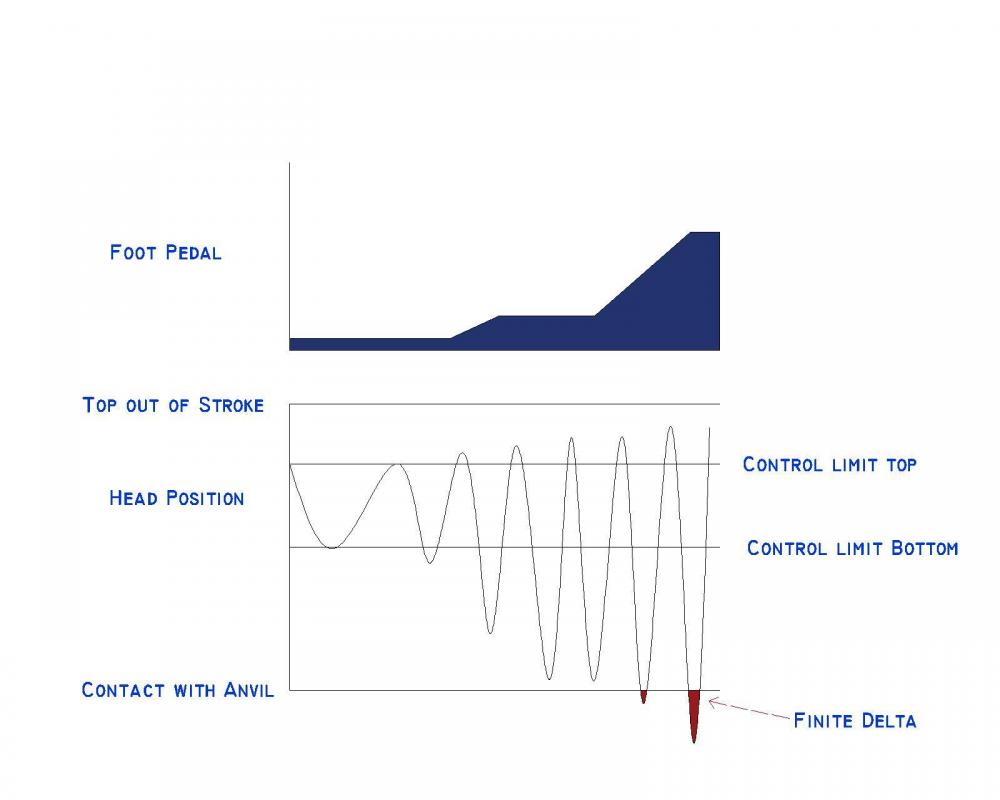

Looks much better. With the hammer dwelling for a while at the bottom (We call this the finite delta time) you may just need to move the bottom trigger or mini valve up some so the hammer has to stretch to hit the material. The hammer never gets into a natural rhythm if the valves are two far apart. That natural rhythm where the head hits air cushion on either top or bottom will make it easier to use IMO. Great to see the videos, Thanks for posting them! Here a chart of what we shoot for as ideal form from a few years back. -

New to Blacksmithing in GA

Anderson G. Phillips replied to blacklabel's topic in Blacksmithing, General Discussion

You should buy a Blu hammer..... but you shouldn't listen to me. No matter what you buy your work is a reflection of the tools you use. Make sure your hammer face is nice and your anvil face is nice. -

Shop sign

Anderson G. Phillips replied to Michael Cochran's topic in Blacksmithing, General Discussion

Hey, Love the sign concept and there are some good thoughts above. I am filming today for our channel here at BLU so I did a quick video on my thoughts on this bracket if you have time to check it out. Good luck and I hope you post up pictures as you build it. Also I would love to see the place where it is going. https://youtu.be/FwNkukUOnr4 -

Rotating Kiss and Die

Anderson G. Phillips replied to Sanderson Iron's topic in Power Hammers, Treadle Hammers, Olivers

Very cool, We use something very much like this for quick changing kiss blocks and like it a lot. That is a good looking tool and nice drawing of your work too. I would love to see it finished. -

Air cylinder port size question

Anderson G. Phillips replied to eseemann's topic in Power Hammers, Treadle Hammers, Olivers

You wont get it right on the first try, and if you do i want to know how you did it. Tuning = Adjustment. So the more slides and bolt together pieces you can design in the better. I would love to see pictures as you go. -

Air cylinder port size question

Anderson G. Phillips replied to eseemann's topic in Power Hammers, Treadle Hammers, Olivers

There is a special spot in my heart for tiny hammers. I like the second picture. The new version of the Kinyon, I think, lend itself well to be made in a tiny hammer. As for port size you can’t ever have enough but timing the cycle of the hammer is far more important than having over sized ports. You should be ok, not great but ok. -

Foot pedal designs for air hammer?

Anderson G. Phillips replied to AdamG's topic in Power Hammers, Treadle Hammers, Olivers

I am a fan of ball valves and toe control. Think about car almost all use toe control and butterfly valves. Maybe not the most flashy engineering choise, but it is simple, easy to build and it work. I am glad to hear your hammer is coming along btw. -

Every friday I host a blacksmith challenge at our shop. Ever sence a few weeks ago we have been going canldle holder crazy at the shop. As for this one, I forged the base about two weeks ago and the cup just yesterday. About a year ago nick ireys forge a seires of candle holders for OHI and serveral of them had this two part candle cup. I liked it alot so i used it here. As well the base is something new we have been playing around with. So have at it. What do you think?

-

Thanks again! In full disclosure these two were made by guys I work with and not me, but they have both enjoyed your critiques and quetions therein.

-

Thanks for all the thoughtful feedback!

-

Between these two candle holder which one do you like better? Oh, and what do you think of them? Thanks!

-

I am doing a video lecture about power hammers in a couple of weeks at this year's Metal Fab and I'm currently putting the finishing touches on it. I am still looking for pictures of cool old and new power hammers, static or in action, to use for background slides and b-roll. Please PM me or post here if you have pictures you are willing to let me use. After the show, the plan is to post the hour long lecture to youtube and I will post a link here. Thank you for all of your help!

-

The Power Hammer Market?

Anderson G. Phillips replied to KYBOY's topic in Power Hammers, Treadle Hammers, Olivers

I think the market has shifted in more ways than one. There is less focus on the nostalgia of the tooling and process and more on the end product and its aesthetic regardless of what it takes to make it look that way by a growing chunk of our sub culture. The range of hammers out there are within reach price wise for many hobbiest and beginner. For less than you might send on a used old Harley that needs some TLC you can get a brand new Anyang 35 (cute as can be they remind me of a sewing machine, but a good forging machine). For less then we spent on my wife’s Sportster when she was still in collage you can get a Big Blu and a compressor. With at least 4 other big names out the for brand new power hammers there is competitions and a good price market too. The market isn’t booming (in large part because of the economy) but it is still very strong. Many who may have felt there best bet for an inexpensive good running hammer was a little giant now are looking to and out of the box new machine for less. -

Power hammer test

Anderson G. Phillips replied to mike-hr's topic in Power Hammers, Treadle Hammers, Olivers

30% or so depending on the way the valves are set. -

Power hammer test

Anderson G. Phillips replied to mike-hr's topic in Power Hammers, Treadle Hammers, Olivers

-

Power hammer test

Anderson G. Phillips replied to mike-hr's topic in Power Hammers, Treadle Hammers, Olivers

Sorry for the absence, between busy work and my new daughter Ferrous sometimes my hobbies suffer. You can get in touch with BLU hammers @ 1 828 437 5348. I can only speak to some of the science of the improvements as I am only a small part of the team that works on the hammers, but it is science and not black magic, well mostly science. There are Four hammers (2x155#, 1x110# and 1x65#) set up to run in the BLU shop in Morganton NC, ( Also they will be set up at the Madison GA meeting) So if you want to try out a hammer or reverse engineer one they are there waiting. But you’re on your own for the engineering. I will post up a link to our YouTube explanation of how the new hammer runs. -

Power hammer test

Anderson G. Phillips replied to mike-hr's topic in Power Hammers, Treadle Hammers, Olivers

But you could be the proud owner of…… no no just kidding, back to the task at hand. Power hammer test. :D -

Power hammer test

Anderson G. Phillips replied to mike-hr's topic in Power Hammers, Treadle Hammers, Olivers

You sound good and excited about the improvements, are you volunteering to make some cold calls? The new hammers are better, that doesn’t mean there anything wrong with the older ones. Of course there is an upgrade kit is available for sale. -

Power hammer test

Anderson G. Phillips replied to mike-hr's topic in Power Hammers, Treadle Hammers, Olivers

A few years ago I had an air compressor I felt just wasn’t living up to my expectations so I pondered on the science of CFM and the art of plumbing that goes in to a blacksmiths shop and finally I decided to call the manufacture. They gave me a simple test. The tech that was helping me said that if I isolated the compressor tank from my air system and started the compressor it should take no less than 6minutes to fill and not more than 7. Tests like that give you are an important tool and can help provide piece of mind when you’re wondering if your hammer is hitting as hard as it could or should be. With an air hammer there are some many variables past just the hammer its self- how is it anchored, are there any anomalies in the air system and is the hammer getting enough air? Then to go a step further with an enclosed hammer, there are any number of things that could be chipping away at your power and performance. A good power hammer test isn’t just a way to get out the old ego measuring stick, but it could be a good tool for people installing new hammers or rebuilding old ones. I think to get a good test you have to all but take the dies out of the equation. That is if all you’re out to measure is the power produced by the hammer. You could do this by making a compact tool that would fit in-between the dies and make an indentation on a piece of stock with a known hardness. Check out the Vickers hardness tester: http://en.wikipedia.org/wiki/Vickers_hardness_test A machine that occupied too much of my time while in school (the good old days a youth waited in making knives and other pointy things) The principal is no less than driving a punch in to a bar. What do you think of this as a way to test a hammer? -

Power hammer test

Anderson G. Phillips replied to mike-hr's topic in Power Hammers, Treadle Hammers, Olivers

Every year the car companies come out with new cars, just because you bought last year and the new model get better gas mileage and has a bit more power doesn’t mean your car is junk. The Quick change hammers are great hammers, but in the hundreds of hammers made since then have been improvements. This is the slow and steady march of progress. If it seems fast it is only because BLU put out allot of hammers. I only sought to point out that the reason for the discrepancy in power was not due to quality control issues but rather two models undergoing the same challenge.