-

Posts

1,095 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Posts posted by Stormcrow

-

-

On 10/2/2020 at 4:10 PM, WhiskeyTangoFoxtrot said:

What are you running for a forge? I have a weird thing about wanting to make some cleavers (maybe not quite as giant as your beauties, but definitely bigger than the ones you get with a knife set)

I'm using a one-burner square body forge I built. The burner is a Larry Zoeller kit, the sides are about 10", used 2" wool insulation, with kiln shelving for the doors and on top of the floor wool insulation. For heat treatment, I have a big Evenheat electric furnace with digital controller.

-

Beautiful, clean work. Love the substitution of the chisel.

-

Thanks, guys!

Frosty - A Sasquatch gets what a Sasquatch asks for!

-

Howdy, folks. Been a busy, productive year, and not as much time has been spent on forums as I used to. But I have had a couple of interesting projects I wanted to share. They are the two largest carcass splitters I've made so far, one completed in February and one in August.

The first was a commission from a chef who owns multiple restaurants who wanted as large a carcass splitter as I could make as a gift for a friend of his. The second was a commission from a fellow who butchers a lot of hogs. Both started out as bars of 5/16" x 4" 80CrV2 steel, and both ended up with hemp cord over neoprene handle wraps and Boltaron sheaths. And both were hair-shaving sharp when shipped.

The first one was forged as close to shape as possible with my power hammer, with only minimal cleanup grinding along the edge profile before grinding and filing the bevel to final dimensions. It ended up with a blade just under 20" long, 5 3/4" wide at the widest, 41 1/4" overall length, and a weight of 8.22 pounds, a good 3 pounds more than my previous largest carcass splitter.

In comparison with a "small" carcass splitter that is more like a 15" blade, 15" tang, and around 4 lb weight, and with a 6' 2" Sasquatch for scale.

The second one was forged as close to final dimensions as I could on my power hammer, but the end was trimmed and the spine had minimal cleanup grinding. It isn't quite as wide, but is larger in all other ways at just over 20" blade length, 5 1/2" wide, and 44" overall lenth, with a weight just over 9 pounds.

It picked up some extra texture from sitting a few days in a mixture of vinegar that had more 30% acidity in it than I realized (most of the mixture was 9% or 5%). Usually the vinegar eats the scale off without affecting the steel; this time it definitely added texture.

In comparison with a 15" bladed bush sword that weighed just under 1.33 lbs prior to stock removal:

Sasquatch for scale.

Gotta say, it does nothing to help you hitch hike, even if you show a little leg! I had just finished demonstrating how it could shave hair, too!

More details, process video and pics, and general silliness in this video:

http://www.youtube.com/watch?v=SrEF1P5Qdh8 -

Thanks, Bill. That was 2001. Been a long journey from there to here, for sure.

-

Thank y'all!

Templehound - You ain't kidding about the discipline thing! I'm trying to get some inventory together for Blade Show West right now. I'm focusing on mid-tech knives, but hope to have some forged blades as well.

-

It's been a busy year, and difficult to keep up with everything. Here's some of what I've been building. It's all 80CrV2 steel with various cord wraps impregnated with marine epoxy and sheathed in Boltaron. I like to focus on getting geometry, balance, and ergonomics right without playing around too much with materials.

Apologies beforehand for the massive wall of pictures.

Mini-parang.

miniparang01 by James Helm, on Flickr

miniparang01 by James Helm, on Flickr

Barong.

barong01 by James Helm, on Flickr

barong01 by James Helm, on Flickr

barong02 by James Helm, on Flickr

barong02 by James Helm, on Flickr

Ko-katana.

kokatana01 by James Helm, on Flickr

kokatana01 by James Helm, on Flickr

kokatana03 by James Helm, on Flickr

kokatana03 by James Helm, on Flickr

kokatana04 by James Helm, on Flickr

kokatana04 by James Helm, on Flickr

Wakizashi.

waki03 by James Helm, on Flickr

waki03 by James Helm, on Flickr

waki04 by James Helm, on Flickr

waki04 by James Helm, on Flickr

Sasquatch for scale.

pose03 by James Helm, on Flickr

pose03 by James Helm, on Flickr

Carcass splitters, two big, two small.

carcasssplitter01 by James Helm, on Flickr

carcasssplitter01 by James Helm, on Flickr

carcasssplitter05 by James Helm, on Flickr

carcasssplitter05 by James Helm, on Flickr

carcasssplitter06 by James Helm, on Flickr

carcasssplitter06 by James Helm, on Flickr

Sasquatch for scale.

carcasssplitter03 by James Helm, on Flickr

carcasssplitter03 by James Helm, on Flickr

Another barong.

barong by James Helm, on Flickr

barong by James Helm, on Flickr

An elvish forester's blade.

forester by James Helm, on Flickr

forester by James Helm, on Flickr

Snake chopper.

snakechopper by James Helm, on Flickr

snakechopper by James Helm, on Flickr

Orange and black bush sword and companion small recurve.

orangeset01 by James Helm, on Flickr

orangeset01 by James Helm, on Flickr

A tenegre bush sword.

tenegre01 by James Helm, on Flickr

tenegre01 by James Helm, on Flickr

tenegre02 by James Helm, on Flickr

tenegre02 by James Helm, on Flickr

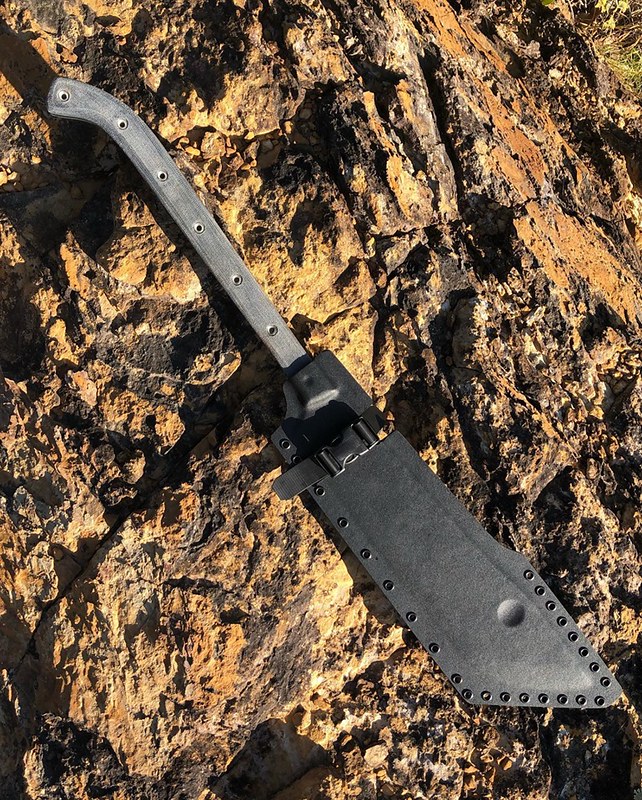

A prototype for an upcoming project. Obviously not a cord-wrapped handle on this one, but TeroTuf slab handles with stainless steel flared tube rivets.

ed01 by James Helm, on Flickr

ed01 by James Helm, on Flickr

ed02 by James Helm, on Flickr

ed02 by James Helm, on Flickr

ed03 by James Helm, on Flickr

ed03 by James Helm, on Flickr

Taco Ninja for scale.

ed04 by James Helm, on Flickr

ed04 by James Helm, on Flickr

Another carcass splitter.

carcasssplitter01 by James Helm, on Flickr

carcasssplitter01 by James Helm, on Flickr

A tiny tanto.

tanto01 by James Helm, on Flickr

tanto01 by James Helm, on Flickr

Sasquatch for scale.

carcasssplitter04 by James Helm, on Flickr

carcasssplitter04 by James Helm, on Flickr

A lamb splitter with TeroTuf scales.

lambsplitter01 by James Helm, on Flickr

lambsplitter01 by James Helm, on Flickr

lambsplitter02 by James Helm, on Flickr

lambsplitter02 by James Helm, on Flickr

lambsplitter03 by James Helm, on Flickr

lambsplitter03 by James Helm, on Flickr

Sasquatch for scale.

lambsplitter04 by James Helm, on Flickr

lambsplitter04 by James Helm, on Flickr

A small-ish camp chopper.

campchopper01 by James Helm, on Flickr

campchopper01 by James Helm, on Flickr

campchopper02 by James Helm, on Flickr

campchopper02 by James Helm, on Flickr

A small-ish ginunting.

ginunting01 by James Helm, on Flickr

ginunting01 by James Helm, on Flickr

ginunting02 by James Helm, on Flickr

ginunting02 by James Helm, on Flickr

Another small-ish camp chopper.

campchopper03 by James Helm, on Flickr

campchopper03 by James Helm, on Flickr

campchopper04 by James Helm, on Flickr

campchopper04 by James Helm, on Flickr

And finally, a decent-sized bush sword that went to a good repeat customer. I could picture Professor Smolder Bravestone picking this up in the bazaar while outfitting for an expedition in Jumanji. :mrgreen:

bushsword01 by James Helm, on Flickr

bushsword01 by James Helm, on Flickr

bushsword02 by James Helm, on Flickr

bushsword02 by James Helm, on Flickr

And now I feel tired.

This is a good bit (not all) of half a year's forged blades (not mid-tech). And, of course, I have any number of projects currently underway.

This is a good bit (not all) of half a year's forged blades (not mid-tech). And, of course, I have any number of projects currently underway.

-

1084, 5160. A pipe muffle will help even out the heat of a coal forge when it comes time to heat treat, and eliminate the risk of burning up the steel. Definitely normalize before you harden and temper.

-

Pretty cool!

-

Very nice!

-

She did better than I did on my first knife!

-

Thank y'all!

Neilyeag - I have no natural skill in that direction, but I'm extremely stubborn!

-

Those are some gorgeous cutting boards, and the knives compliment them well!

-

Been busy banging out bodadacious blades. Here are some recents. 80CrV2 steel, cord wraps, and Boltaron sheaths all around.

A biohazard outbreak reaction bush sword and smaller utility knife that went to a repeat customer in Canada. The bush sword has scorched hemp for the main wrap and black paracord Turk's head knots. The smaller knife has tan paracord over hemp, with a black paracord Turk's head.

A similarly-sized (6"~ blade) knife as the above utility, with hemp.

Variations on Benghazi Warfighters, two with sharpened upper edges.

A Benghazi Warfighter with black oxide finish, headed to an Army Ranger. He had commissioned a bigger chopper/fighter from me a few years ago, a variation of my Aggression design (I need to make some more of those). We decided this was a "micro-Aggression" and the sheath is a "safe space" from it.

He can't tell me yet where he's deploying, but this is going with him.

He can't tell me yet where he's deploying, but this is going with him.

A couple of donation blades, the first for Knife Rights in their continued fight to remove restrictions on the ability of law-abiding citizens to carry arms in the United States. This year, a falcata-ish bush sword with retina-searing neon orange underlay.

I don't realize how big my hands look until I take a picture of me holding a blade.

And a much smaller donation knife for my old high school, raising funds for teacher projects that run outside the school budget.

One of the most useful comments I've had on my work came years ago when a knife dealer told me my blades were good but my sheaths sucked. I have worked to make that better, and think I have achieved a decent level of workmanlike sheaths.

And finally, the first oxtail dao I've done in a long time. The customer had as reference a picture of one I built many years ago.

Here's what I came up with for him. He was quite taken with the results.

I'd say I've improved through the years. The top edge is fully sharpened on the new one.

The design called for an open-backed sheath.

Ok, headed to the shop to work on some carcass splitters.

-

Beautiful work and a great story. Really love the blade shape and have built similar before in my own style.

Glad to see you bring it out of the cabinet and put it to work.

-

Yep. Look at the product first, with the maker adding a bit of secondary interest afterward. I'm so white I could send emergency signals just by rolling up my pants legs and going for a walk. I've drawn inspiration from makers around the world, most of whom don't look a thing like me.

There is a strong, vibrant Asian knifemaker community in various countries. I follow several from Thailand on Facebook and Instagram. No idea what their text says, but their work is beautiful, and they obviously keep a close eye on what is going on in the American market. I've seen pieces inspired by Scagel, Cohea, and Rhea, in addition to more Oriental stylings, both Thai and from other Asian styles. They build their own 2" x 72" grinders, hydraulic forging presses, and salt pots, and have their own version of Blade Sports. They didn't look over here and turn up their noses because most of us don't look like they do. They learned, adapted to their own styles, and are an inspiration to a number of us on this side of the Pacific.

There are several Japanese and Chinese knife magazines that I have seen pictures of. I can't tell you any titles since I don't speak or read the languages, but they don't hesitate to put the work of old white men in them next to more local makers.

-

Thank y'all!

Thad - On smaller blades I temper at 425 Fahrenheit, on larger ones, 450. I have a whole HT schedule from Ed Braun I'll send anyone interested if they'll send me an e-mail at helmforge at gmail with the subject line "80CrV2 HT".

Templehound - The milled bevels are a smidge thicker than I'd like, but we're going to be adding a smoothing pass that'll shave it down a bit thinner. I want to heat treat at the point that they're ready to be sharpened. These were done with a 5 degree tapered end mill, but future ones will have a 3 degree mill, so the bevel will come higher up the blade and be thinner. We broke our 3 degree end mill on the second pass due to a mistake on our part and swapped to the 5 degree to finish out testing our proof-of-concept.

-

It's been a very busy last several months, and while I have produced a good number of blades, I haven't been as active online to post them. So here's most of them from recent months.

Everything is 80CrV2 steel, with various combinations of paracord and hemp wrapped handles, and Boltaron sheaths except for the two retina-searing colors, which are Kydex.

In vague order from November to February:

This chopper was forged very close to the final shape. Minimal stock removal on the bevels.

A rare foldover sheath:

My eyes!

Not the same tan tanto as above.

A very rare kiridashi.

O tanto with a 13 1/2" blade and wakizashi with a 15 3/4" blade. The waki was a commission from a Green Beret.

This 9" recurve was finished just in time to be a Christmas gift.

Did a number of ginuntings, have more in the future.

My eyes!

Hey, look, a midtech Little Rok with CNC machined bevels! Slowly making progress.

-

Meticulous!

-

Thank y'all!

Thad - The cord is quite variable in how thick it is, which can be aggravating. I make sure the wrap is tight, so that the variable thickness adds to the texture. Hemp cord is the grippiest handle material I've encountered, and that contributes to it.

-

Chuck Burrows was primarily a leatherworker, but he had a good number of collaborations with knifemakers (Gib and Tai being the ones I know about the most) where they supplied a blade and he did all of the handle work, fittings, sheath, and display stand, giving the finished piece his own distinctive style, hence me including him.

-

The customer has assured me that the lamb splitter will be used for butchering.

-

A couple of new big blades that got shipped out earlier this month. Two firsts on these: the cord-wrapped one is the heaviest I've made, and the slab handle on the lamb splitter is the longest slab I've ever made.

Both of them are forged from 80CrV2 steel with Boltaron sheaths.

The wrapped one has an 18" blade and weighs 5.14 pounds, the first of mine to weigh more than 5 pounds. The handle is 22" long, scorched hemp on top of a neoprene foundation, with West System marine epoxy.

It was a Christmas gift from a wife to her husband, and she had me laser engrave this on the blade.

The lamb splitter is an over-sized version of what is usually a large one-handed butcher knife-looking blade. The blade is 17 1/4", the handle is 17", and the weight is 4.125 pounds. It has the longest slab handle I've ever made, from tan TeroTuf with flared stainless steel tube rivets.

by James Helm

More details in the video:

-

Thank y'all!

Teonanacatl

in Knife Making

Posted

Well-kneaded indeed!