-

Posts

34 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by David Roeder

-

-

- David Roeder Knives

- David Roeder

- (and 4 more)

-

-

- David Roeder

- Brut De Forge

- (and 6 more)

-

-

- Bowie Knife

- Damascus Knife

- (and 8 more)

-

-

- Frame handle knife

- Damascus

- (and 6 more)

-

-

- David Roeder

- A.B.S. Knife

- (and 5 more)

-

-

- David Roeder

- Journeyman Smith Knives

- (and 6 more)

-

- 2 comments

-

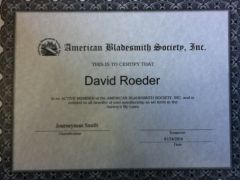

- American Bladesmith Society

- Journeyman Smith

-

(and 1 more)

Tagged with:

-

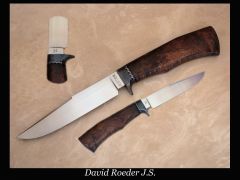

This is the set of knives that will be presented to the American Bladesmith Society judging board in San Antonio Texas on January 25, 2014. These knives are being judged for my advancement to Journeyman Smith. Each Knife is forged from 5160 carbon steel. Handle material varies between cocobolo wood and stabilized Koa. The guards are 416 stainless steel. The knife pictured at bottom is the performance knife. It passed all testing including the 90 degree flex test and did not crack ! The handle material is Blue G-10. I began making knives in September of 1996. The gentleman responsible for getting me started along is Billy Jo Brown of Live Oak Fla. His work at the time was simply astonishing to me at the age of only 16, and to see the process of making such a tool and forging it from a coil spring was enough to set the hook. These many years later I decided to take the steps and met my requirements to be judged for Journeyman Smith by the A.B.S. The days now I look back at my younger years and my early efforts in knifemaking and just have to smile. It's been a long road leading to this, but for all the knifemkers that I have met and the interesting projects I've done I must say that I wouldn't trade it for anything. Thank you Billy Jo Brown for setting the hook, Joel Stuart for his advise and help in my beginnings, he will be missed ! Randy Spanjer, John Davis, Gary House, Ed Schempp, and especially Tommy Morris for your friendship over the years.

- 3 comments

-

- J.S.

- Journeyman Smith

- (and 7 more)

-

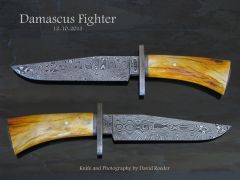

208 Layer random ladder pattern Damascus fighter. Damascus blade, guard, collar, and an inlay butt plate. Handle material is dyed and stabilized white tail deer antler. Blade : 208 Layer random Ladder pattern Damascus. 1095 & 15n20 6 1/8" long Handle material : Dyed and stabilized Whitetail deer antler.

-

- Damascus

- David Roeder

- (and 7 more)

-

-

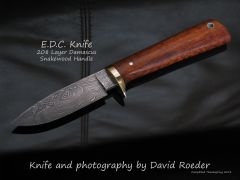

- EDC Knife

- David Roeder

-

(and 5 more)

Tagged with:

-

-

- David Roeder Knife

- Custom Knife

-

(and 5 more)

Tagged with:

-

-

- Forged

- David Roeder

-

(and 3 more)

Tagged with:

-

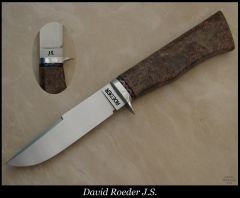

This is a recent piece for a international client. This knife was made and sent to a client in N.E. Ireland. The blade is 5160, and the handle material is stabilized Bog Oak. The client and I using Skype were able to talk face to face so to speak, and he was able to watch the entire making of his knife. What a wonderful bit of technology when two people from so far away can talk face to face.

- 1 comment

-

- David Roeder Knife

- Custom Knifemaking

- (and 8 more)

-

-

- David Roeder

- Hand Forged

-

(and 3 more)

Tagged with:

-

October 19, 2013 Here is the final set of 5 knives for my Journeyman Smith Test. Each blade is forged from 5160 carbon steel. 416 Stainless guards, and cocobolo wood handles. I chose to use the same material for the knives because they were all being made for the same purpose. These knives end a very long time period for me. At this point in my life I am 33 years old. I have been making knives now for 17 years. I was taught knife making originally by a knife maker in Live Oak Fla. by the name of Billy Jo Brown. He helped me spark the interest in making knives by forging and working the steel to create such wonderful pieces. I am forever grateful to B.J. for taking the time with me so many years ago.

-

- Journeyman Smith Knives

- ABS Knives

- (and 8 more)

-

-

- David Roeder

- Custom Knife

- (and 4 more)

-

#2 of 5 A.B.S. Journeyman Smith examination knives by David Roeder

David Roeder posted a gallery image in Knives

-

- David Roeder

- Custom Knife

-

(and 3 more)

Tagged with:

-

-

- Knife

- Knifemaking

-

(and 5 more)

Tagged with:

-

- 3 comments

-

- Anvil

- David Roeder

-

(and 1 more)

Tagged with:

-

- 3 comments

-

- Anvil

- David Roeder

-

(and 1 more)

Tagged with:

-

-

- English Wheel

- David Roeder

-

(and 1 more)

Tagged with:

-

- 1 comment

-

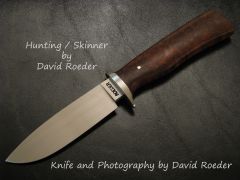

- Custom Knife

- Hunting Knife

- (and 8 more)

-

- 1 comment

-

- Damascus Knife

- Custom Knife

-

(and 3 more)

Tagged with: