-

Posts

1,195 -

Joined

-

Last visited

Content Type

Profiles

Forums

Articles

Gallery

Downloads

Events

Everything posted by matto

-

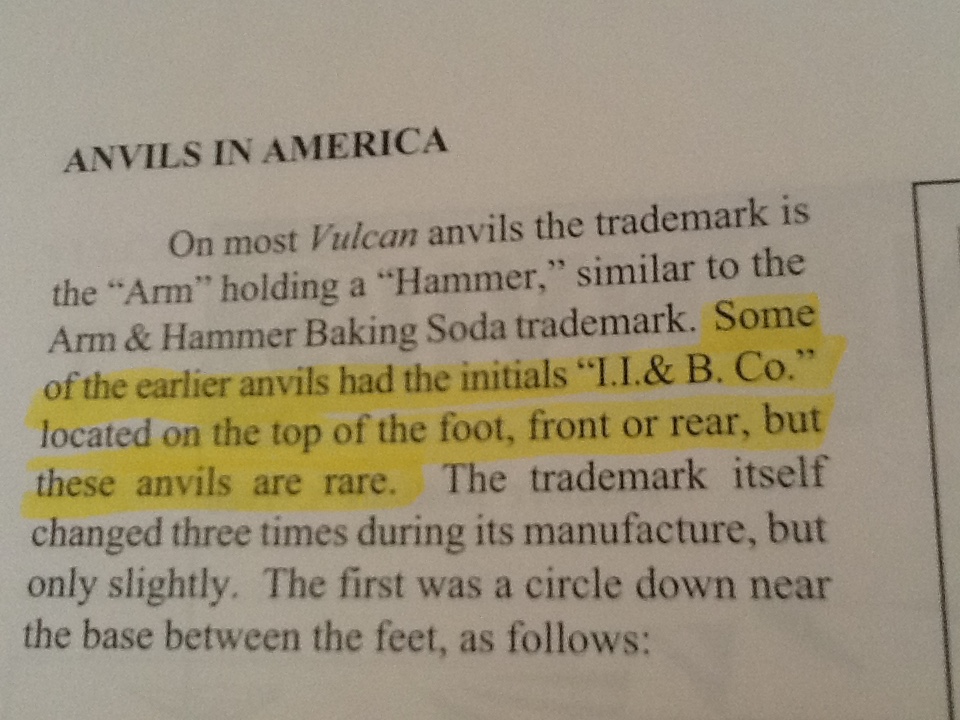

Do you believe every advertisement you read or look at to be the way it will be?? All the pics with fisher under the heel on the foot are advertising pics. In the 11 pics of the actual anvils 6 of them the fisher is on the front foot under the horn. In the ad pics it is good marketing to put the company name where the buyer will see it... Hence if you are looking at a drawing of the back the name of the company is more important than the date of manufacturing. Hence the fisher name on the foot under the heel. It is just an ad. Also the 30 to forty fishers I have seen all have the fisher on the front foot under the horn.

-

I think you are confused the pic (you are showing) in the book has FISHER on the left foot under the horn for that particular 1913 anvil. the horn is the pointy thing on the right in the pic. As for the one in the shop pic can't see the foot under the horn just the date under the heel and the logo in the body.

-

Hope to have it cleaned up this weekend. Will post pics.

-

Frosty that is what my plan was. Should make a fun little forge.

-

Arkie my dad has a similar story from when he was at tech school. The tech school in Hastings was in the old ammo factory and storage yard. It was miles of dirt covered bunkers for storage of ammo and equipment in World War One and two. There were rail tracks going around all of them. After class dad and his buddies would get into dads 56 Chevy and head for the tracks. He said they would turn on to the tracks and get lined up square on them then let some of the air out of the tires to hug the track and they would go rabbit hunting for the afternoon driving in and out around the dirt bunkers. He still thinks it is amazing how well a 56 Chevy fit on the tracks.

-

Thanks Arkie I will look in to it, Yaggy crazy thing is it was still cold and aged nicely. Arkie neat video on the Johnson. Now I need to get it cleaned up and running.

-

-

Thanks DSW and Frosty, I was thinking it might be asbestos and will try contacting Johnson gas.

-

Thomas I have a manuel coming from Miller and will start taking it apart and cleaning it up this weekend. Michael I have my grandpas old thunder bolt. He got it in the late 60s or early 70s. Fun little welder.

-

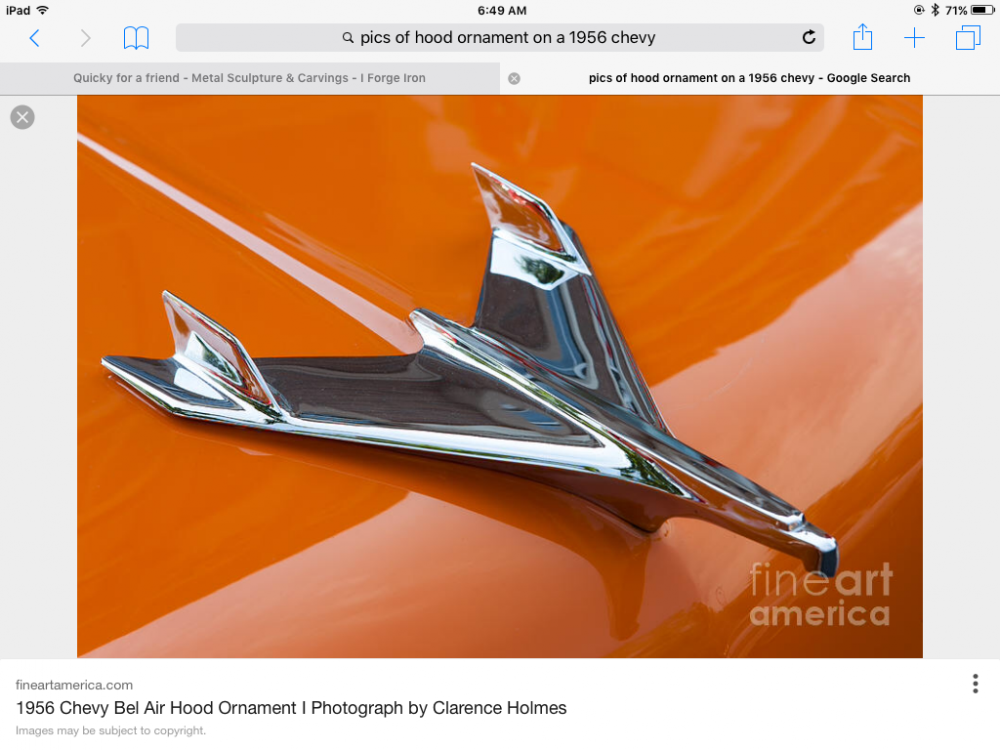

I was thinking of the eagle on a 56 Chevy. Two up turned end wings. Hits both inter thighs at once.

-

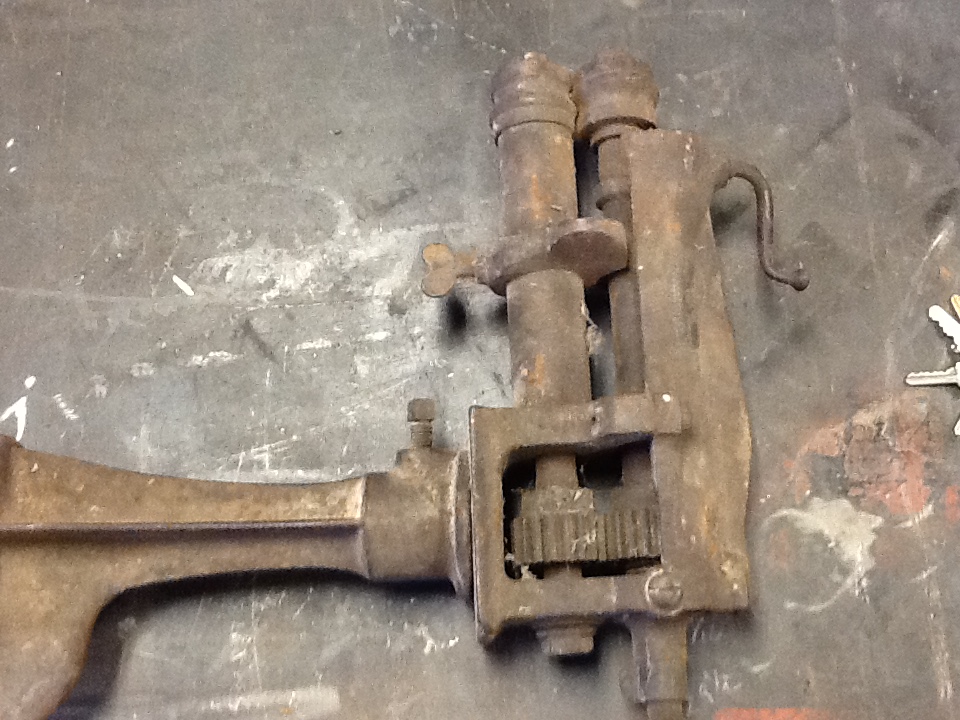

Ya I am existed to get it cleaned up and start rolling with it. I also what it see if I can make a mini gas forge out of the soldering iron heater. Think it would be kinda fun.

-

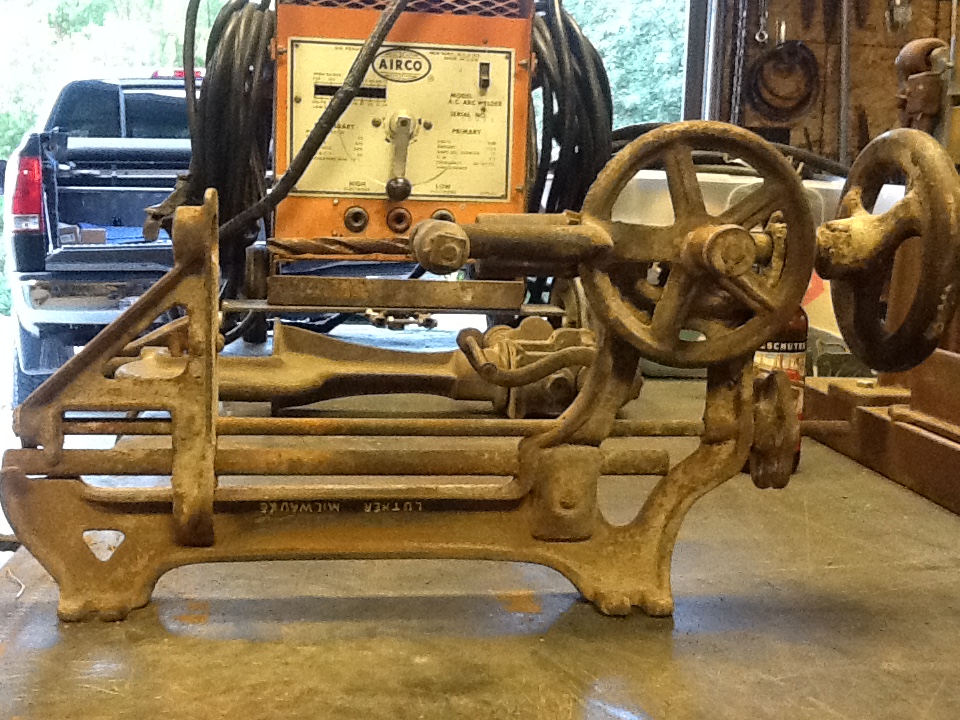

Some things I found in an old building old Allen wrenches big ones are 1 3/16" and 1 1/8" cute little post drill and I think it is a soldering iron heater??

-

Replaced power cord and fires up great. All resurch I have done on it states that pre 1963 where all made by Miller. I will get it all cleaned up and replace worn parts. Miller still list and has parts for them.

-

Ended up in my truck. Guys dad bought it used in 1958 then used it for the next 50 years. Was made by Miller for Airco

-

Das call up your buddy or send him a my little pony to put in the dragons mouth.

-

No pics on the hood???

-

Great news and you all are sill in our prayers!!

-

Still fun!!

-

Had a 14" cutoff wheel blow up into my shins when I was cutting some angle iron bridging. The guy that used it before me changed the blade but did not tighten it up because he had to get to lunch. I fired up the demo saw and got wheel imbedded into my shin. He on the other hand got a spud wrench imbedded in his shin.

-

That is one really clean anvil,. A lot of style and grace. Would be tempting, make an offer But my 275lb rifflinghaus made in 2015 was $2100 and has a life time warranty.

-

What would the best size be?? a slab of granite is about 120"x 78"

-

Iron dwarf what and how would you use a granite table?? I have always been wondering do to the fact I run a stone countertop shop. All our stone is 3cm thick. I can laminate two pieces to make 6cm but talk about heavy. Would it be good to put a granite table in my shop? How is it going to react to welding and everything else?? What is the advantage?

-

-

Could be the number of the person that put the molds together for that anvil or the person that inspected it.