All Activity

- Past hour

-

Steel from old garage door springs

PaperPatched replied to Ronin66's topic in Blacksmithing, General Discussion

And if you can tolerate paying more any good hardware store will have new ones. -

Yeah, I was cross checking a 1910 S&R catalogue and the most expensive vise I saw was a $4.97 swivel vise! Keep it fun, David

-

Casting a Gingery Lathe

Frosty replied to Nobody Special's topic in Smelting, Melting, Foundry, and Casting

You're progressing pretty well for not having hands on instruction. when you say you're judging the al temp by incandescence, incandescence of what? Certainly NOT the aluminum, it should barely show color in night time dark. Judge it's readiness to pour by how it feels when you stir it. You DO stir it in the crucible, at least when mixing the flux, yes? Molten aluminum has a distinctive feel when it's the right temp to pour, getting it hotter doesn't help and often makes things much worse. Next time melt at least 50& more than you think you'll need. Weigh the most complete one you've cast and add at least 50% more to the melt. That is why you make ingot molds after all. BECAUSE there is always extra melt and you'd be crazy to let it freeze in the crucible. Yes? Make ingot molds from angle iron in lengths about 1/2 the depth of your crucible. Weld a bunch touching sides between a couple pieces of strap stock. You don't need to weld the ends solid the al will solidify before much can leak through a tight contact fit. Once the ingots are cooled flip it over so it bangs on the ground and the ingots will fall right out. Muffin tins work but pressed steel ones don't last very long but cast iron ones don't take to being banged. Then again I've seen corn bread pan ingots in the shape of little cobs of corn. Soooo. Frosty The Lucky. -

Now there's a thought. Keep a nest or 5 of domesticated packrats behind the back stop at the gun range to collect the jackets, and lead for scrap value. No, I'm not forgetting casing at the firing line but those sweep up of the pavement, it makes for easy clean up of the brass you know. Frosty The Lucky.

-

Casting a Gingery Lathe

Nobody Special replied to Nobody Special's topic in Smelting, Melting, Foundry, and Casting

Some updates - The baked cores for some reason expanded and wouldn't fit in the pattern. Who knew? I made a second attempt and screwed up the pour, which was maybe a bit too cold, and the sprue froze/clogged and I get a huge mess. Third attempt - my ramming has gotten much better, I used incandescence to judge the temperature (at night), I've taken to hand packing the cores into the pattern to avoid flipping it, and I added a touch of bentonite to the sand and tempered it a bit further, which helped tremendously...and then I shorted the crucible by maybe 20 ounces or so...bottom of number two, and the aftermath of number three in the pics below. - Today

-

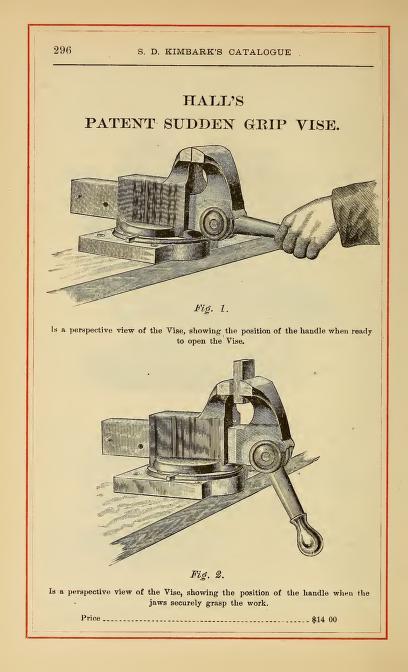

Bingo Scott! It doesn't show in Vintage Vises. A web search for "Halls Sudden Grip Vise" found that very catalogue page. I've read about the type if not these vises before too, if not here then maybe on one of the vintage tool fora. Thomas probably pointed us to it it'd be right up his alley. I lost track of where that thread lives, probably in the bowels of my old laptop. No matter what the computer tech says they never transfer ALL your data. <sigh> That is a great family story Nimrod, thanks for sharing. I ran it by a current inflation calculator and it looks like it cost around $408.66 in 2024 dollars. I hope you find bench space for it at 79' I'm pretty sure it'd enjoy a couple few more generations hammering away on it. I wonder how it'd far here at 4x the elevation? 380' above mean sea level whatever it is at any given second in the Knik Arm of Cook Inlet. Frosty The Lucky.

- Yesterday

-

The US Department of Labor's inflation calculator only goes back to 1913. $14 in 1913 equal $446.19 in March, 2024. So, that vise was definitely an expensive one when new. Cool family story. I don't know if I could tolerate the thickness of the air at 79', particularly when you add the humidity and the heat. I'll stay here up on the hill, thank you. Better thee than me. "By hammer and hand all arts do stand."

-

Nimrod, and to answer Goods question, that catalog is copywrited 1876 (not sure of mfg dates of vises though) and can found on the Internet Archive. Very nice story.

-

Curio's, Curiosities and Artifacts

Irondragon Forge ClayWorks replied to Scott NC's topic in Everything Else

That's probably a pack rat. I once cast about a hundred lead round balls for my 50 cal. muzzleloader's and without thinking, I left them on the bench to cool down and forgot to go back to the shop and box them up until several days later. When I went out to get them about half were gone, found them a month or 2 later in a pack rats nest while digging through stuff on one of my many shelves, looking for something else. I can't control the wind, all I can do is adjust my sail’s. Semper Paratus -

Looks to be cast iron, likely tool steel top plate? Yours is in good condition. its special to have family heirlooms that you get to use!

-

I’d like some help with vise identification.

NimrodPhinney replied to NimrodPhinney's topic in Vises

Scott NC. That looks like you nailed it. Thanks. thanks to all for the replies. For anyone who is interested in its provenance, I can safely say that this vice has been in my family since at least 1879. I’ve done quite a bit of research in my paternal families heritage via ancestry dot com and believe that my 4th Great Grandfather left Kentucky with this vise to St. Louis and in 1880 purchased a pocket watch along with a British Bulldog .44 pistol. (Both of which I have). These three items made it across the plains, thru Colorado and to California then in 1899 to Detroit. The vise was attached to a bench in the city of Detroit where my great grandfather, grandfather father and I would beat the ever loving shit out of it on that bench until I removed it about 20 years ago. It sat on the bottom of my bench until I moved to Florida where it sits on the bottom of a bench. I feel that this vise is considerably older than 1879. so I thank you all from the nose bleed elevation of 79’ above sea level just north of Tampa, Florida. -

I’d like some help with vise identification.

Irondragon Forge ClayWorks replied to NimrodPhinney's topic in Vises

I think it may be here. https://www.vintagevises.com/vise_library.html What's one more rabbit hole to fall down. I can't control the wind, all I can do is adjust my sail’s. Semper Paratus -

When was that published? I was struck by the $14 price. Seems like an expensive type!

-

I’d like some help with vise identification.

Irondragon Forge ClayWorks replied to NimrodPhinney's topic in Vises

Looks like you nailed it Scott, I think I have seen a story about them in another forum, but can't for the life of me can't remember which one. I'll check in my bookmarks to see if I can find it. I can't control the wind, all I can do is adjust my sail’s. Semper Paratus -

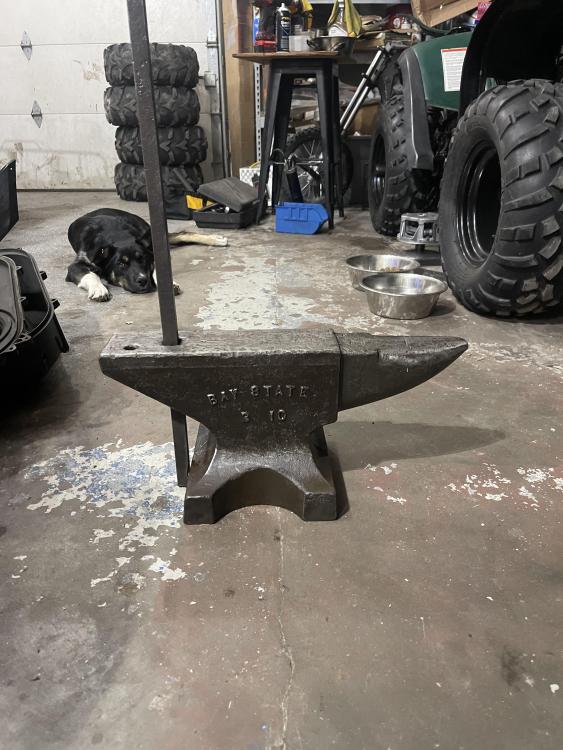

Welcome from the Ozark Mountains. It looks like a pretty nice anvil and having the history on it is a plus as far as I'm concerned. I hope you have read about not doing any grinding, milling or welding on the hardened steel face, which will do more harm than good. Hammering hot steel on it will help to shine up the face and help with the roughness. Have you done a ring & rebound test to see if the face is still hard? There is a trick to doing a good search on the forum, put in your search term and add site:iforgeiron.com to the end of the search string. Sadly the search feature on the forum leaves a lot to be desired. I tried that and here is but one hit. https://www.iforgeiron.com/topic/50283-bay-state-anvil/ I can't control the wind, all I can do is adjust my sail’s. Semper Paratus

-

Wouldn't any of us. At scrap rate probably $7500. Likely worth more, and just plain neat. Only copper I find on our property with a metal detector is pennies and copper jackets from bullets up where we shoot. Some sort of critter likes to make little piles of lead and copper.

-

Steel from old garage door springs

Irondragon Forge ClayWorks replied to Ronin66's topic in Blacksmithing, General Discussion

Welcome from the Ozark Mountains. It would help to know where in the world you are located, most places around here that install and repair garage doors usually have a bunch of them and are happy to give me all I care to carry away. We also have a scrap yard that will sell them at the going rate for steel scrap. I can't control the wind, all I can do is adjust my sail’s. Semper Paratus -

carcrazy_1 joined the community

-

I have a pretty nice Bay State b 10 anvil from our family farm one of my grandfathers bought new. Just curious if there are others as i can find 1 picture on this forum and no other info.

-

-

In an IFI context, it makes more sense to add a comment to a thread you want to resurrect than it does to post a link to it. The former gets the original conversation going again, while the latter can create a separate discussion.

-

Thanks Beaver CR, tinning and brazing in place sounds good to me. Tinning and clamping parts to be brazed is pretty standard when there isn't space or there is too much distance to rely on the hard solder to flow reliably. Do you use a past bronze? There are products available that are fluxed bronze or almost any alloy hard solder you can spread in the joint, clamp and heat. I've never used one but if I were in the business. . . Frosty The Lucky.

-

Now I want to try it so that you can know someone who has done it! if done properly, wouldn’t it be just as secure as the easy way?

-

A ballista would be fun. On further thought I have made log cabin tools with leaf spring though not draw knives. Slicks flat, curved, etc. and a couple froes. The froes were kind of different and used for splitting firewood at the stove not making cedar shakes. Frosty The Lucky.

-

Be nice to turn up something like that digging in our land. Frosty The Lucky.

-

Or linking another thread because it contains something relevant to the topic being discussed. You see marketers bumping ads so they're always at the top of search results. I run adblock to keep ads and bumpers off my screen but they sneak through anyway. Worse they advertise their marketing "service" boasting of their ability to keep your ad at the top of search results. Targeted advertising is often aimed at one word or combination in a search. I think I'm getting a handle on how Bumping applies to IFI. Frosty The Lucky.