All Activity

- Today

-

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

Sodium hypochlorite pumped into the well, or as most people call it bleach. (yes i did have to look up the name) We had one of those whole house filter systems but i did nothing for the smell of the water. -

maskatiya joined the community

-

Mujahid Abbas joined the community

-

Frosty, I agree with you for rings bent the hard way- but I found for thin stock rings bent the easy way it is more finnicky to try and scarf them to weld flat.

-

Excavations at Sheffield Castle

Irondragon Forge ClayWorks replied to Scott NC's topic in Historical Ironwork

Haywire is a standard for me. As far as the bumping thing, as I understand it from warnings I've received on another forum, it is when you go into a post you made, say in tailgating and it doesn't get much traffic and you go in and post something like "bump" to move it to the top of the list to give the post more visibility. That is frowned upon. Also like Scott said if you go start a new thread and link another thread without posting something it's considered "bumping", but if you go into the other thread and add a post to it it's not bumping but reviving an old thread. Now I think I'm confused too. I can't control the wind, all I can do is adjust my sail’s. Semper Paratus -

What did you do in the shop today?

Frosty replied to Mark Ling's topic in Blacksmithing, General Discussion

Billy: Your water smelled of sulfur because pyrite is iron sulfide and degrades into rust and sulfur compounds hence aroma. Do you remember how your lady de-stinked your water? IIRC charcoal filters work for sulfur but I'm not sure. Frosty The Lucky. -

Thanks for the greeting guys! I'm a lifelong woodworker and not planning on starting a new hobby now. My plan is to find out what I have and get it into the hands of someone who knows how to use it. It's too heavy to be lifted alone. My guess it's 150 - 180lbs. The only marking are the name and A87. Is there a location that might have more marking? The anvil has a nice ring when tapped with a small hammer front to back. I will try locate a ball bearing for a better test. Thanks for the information!

-

What did you do in the shop today?

George N. M. replied to Mark Ling's topic in Blacksmithing, General Discussion

One of the big uses of sand is to prop open the cracks created by high pressure in fracking to increase oil and gas recovery. The cracks in the reservoir rock are created by high pressure and then a sand slurry is pumped in to hold the cracks open when the pressure is released. Some of the best sand is produced along the Mississippi River in MN, WI, and IA. And the deposits are becoming depleated. Also, some alluvial sand and sandstone is unsuitable for some uses because of trace minerals. The sand and river gravel around here is unsuitable for making concrete because it has a small amount of volcanic rocks in it which have an origin in the headwaters of the Laramie River about 60 miles away in Colorado. The volcanic rocks react with the cement in the concrete and cause it to crack and weather prematurely. Sand used in glass making has to be very pure and much of any other minerals as trace constituents make it unsuitable. GNM -

Welcome aboard Nimrod, glad to have you. As suggested putting your general location in the header can make all the difference, so much of the draft is location specific. Does your vise advance a little every time you move the handle or do you slide it into contact and tighten it with the handle? I've seen pics of "cam drive" rather than screw vises before but can't find a bookmark in my tools or blacksmithing files. <sigh> I did a quick scan of my favorite vise website but just a quick skim and didn't see the type. However, they answer questions about vises like this gang answers questions about blacksmithing. I don't think Vintage Vises is a commercial site so it should be okay to post here. https://www.vintagevises.com/ Frosty The Lucky.

-

What did you do in the shop today?

Hefty replied to Mark Ling's topic in Blacksmithing, General Discussion

Until I checked which words were capitalised, the title of the second song you listed had a very different meaning!! -

What did you do in the shop today?

Nobody Special replied to Mark Ling's topic in Blacksmithing, General Discussion

I don't know ALL the verses, but I can sing Which Side Are You On and the Union Maid drunk, blindfolded, and backwards...and for that matter the regular way. Also, thank you for that ear worm, my wife just asked why I was going around the house singing "Oh Christmas Tree". Sigh... You're right about the sand. Want a weirder fact? They're running out. Different kinds of sand have very different kinds of uses depending on the composition, size, and sharpness of the corners making it up. Sand found say in the desert is no good for construction and cement making because it's rounded off from centuries of exposure and erosion. I don't think this is the article I was looking for, but... The Story Of Sand In 'The World In A Grain' : NPR Or did ya mean the one by Connell to the other tune? -

If you lap the join on rings so they lay flat on the anvil you don't need to weld them on a horn or mandrel. By flat visualize a coil spring cut in a ring with a little overlap. The ends will lay one on the other while the ring lays flat. Yes? Don't let what works for me stop you from using your horn as you wish. This craft is different for all of us, what works for one doesn't mean diddly for others. There are so many ways to do any one thing there is just no telling. Frosty The Lucky.

-

Welcome aboard Paul, glad to have you. Do you blacksmith or are you flipping this anvil? Kohlswa are Swedish cast steel anvils and top shelf. As to what it weighs, put it on a bathroom scale and tell us. You don't show what is stamped in the side which is often where the actual as made stats are. Depending on who ordered it made of course. What someone somewhere wrote with a paint stick is pretty useless. The number stamped in the foot could be a company ID, a store stock/model#, etc. It looks to be in excellent condition so unless it's been through a fire and had the temper drawn down to far it should fetch good money. Do a rebound test to see if she's still hard or maybe have had torch damage. Drop a 3/8" - 1/2" ball bearing from 10" and read how far it bounces back up in inches as a %. A Kohlswa in undamaged condition will have a rebound in the 90% range, older ones say 1970 and older will rebound higher. Whatever it weighs if you decide to get into blacksmithing you couldn't ask for a better anvil. Frosty The Lucky.

-

Welding is easy once you forget it’s hard. I tend to do sloppy, dirty welds- I rarely scarf or upset, I get it too hot, I don’t flux- and sometimes it doesn’t work. But I suppose it all goes to show that there is a spectrum of “right” ways to weld. Smarter blacksmiths than me have failed with more precise parameters. have fun with welding

-

I'm hoping to practice more welding this summer so I can see how using the horn would be nice for making big rings.

-

Welcome aboard! That’s a very nice looking anvil, near mint condition . Good score! Frosty will be along shortly to congratulate you as well- he’s the local expert of Coleslaw anvils

-

Pal-Lab started following Kohlswa Marking A87

-

I just came into possess of a Kohlswa anvil. I'm trying to get some information on it, model, age and weight. It has A87 stamped on side of the base, what is that telling me? It also has the numbers 168 painted on the base under the horn. I'm thinking this anvil was weigh and marked for auction at some point. I'm including pics and would like opinions on quality and condition, as I will be sell it at some point. Thanks Paul North Georgia

- Yesterday

-

Welcome aboard from 7500' in SE Wyoming. Glad to have you. It would help if you put your general location in your profile. This is a world wide forum and we don't know if you are in St.Petersburg, Russia, St. Petersburg, Alaska, or the middle of the Amazon Basin. Very nice vise. I don't think I've ever seen one with a cam and handle rather than a screw. I can't help with ID but there may be someone here who can. "By hammer and hand all arts do stand."

-

NimrodPhinney started following I’d like some help with vise identification.

-

So, I have a vice that’s been in my paternal family line for over 100 years. I’ve tried to identify it on line, but, as it has no casting marks or proofs, I’m at a loss. The jaws are 3 1/2” wide and the mouth extends to 5”. It has a working lever/cam and man, does it crank down and hold a piece of metal. Again, it has absolutely no markings anywhere. thanks for your time.

-

NimrodPhinney joined the community

-

Markc9126 joined the community

-

Welcome aboard from 7500' in SE Wyoming. Glad to have you. As you can tell, there seem to be a higher percentage of veterans on IFI than in the general population. We've got all the wars from Viet Nam on and all branches of the military covered. Yes, blacksmithing is great therapy for whatever ails you. I've been at it since 1977 and it has helped me through the rough times and made the good times better. I recommend it for most everyone. George LTC, US Army (Ret) late of 1/C/1/12 Cav, 1 Cav Div (Air mobile), Republic of Viet Nam, 1970-71

-

I'm just starting in blacksmithing, taking basic classes at Chicago Ave Fire Arts Center in Minneapolis, a tool making class at North House Folk School in Grand Marais, MN, and I've done a number of art welding and metal fabrication classes through the community ed program at the local tech college. I enlisted in the WI Army National Guard on Friday, April 13, 2001. I was a 92Y (unit supply/armorer) in a Combat Engineer Battalion (wheeled). My last name is Riederer (Reed-er-er). I went through Basic Training as "Private Reindeer" - hence the user name. I'm thinking about using it as the business name if I can start to sell products. I was halfway through spring semester of my Junior year in college when I got a phone call during mid-terms week, telling me to report for active duty in 10 days. I lined up outside the registrars office at 7:45 the next morning along with dozens of other reservists, and dropped 18 credits of classes I was acing. My unit mobilized through Ft. McCoy, WI in March 2003. We hit Camp Virginia, Kuwait in May. On my 21st birthday in early June I rode into Iraq behind a machinegun. At the end of the road, right before we turned onto Tallil AB, these Arab guys were yelling "Mister, Mister... Whiskey... Ice... Beer!!!" But we couldn't stop!!!! That isthe kind of stuff that gives a guy from Wisconsin PTSD... screw the mortars and the IEDs. I got out of the Guard in 2007, I did two years with an Army Reserve unit rather than get yanked back from the IRR for another deployment. Got out in 2009 as a newlywed, rather than go to Afghanistan. Now I'm divorced and working for the Army Corps of Engineers as a civilian. I'm learning to pound metal to stay sane and release some creative energy.

-

Reindeer Forge joined the community

-

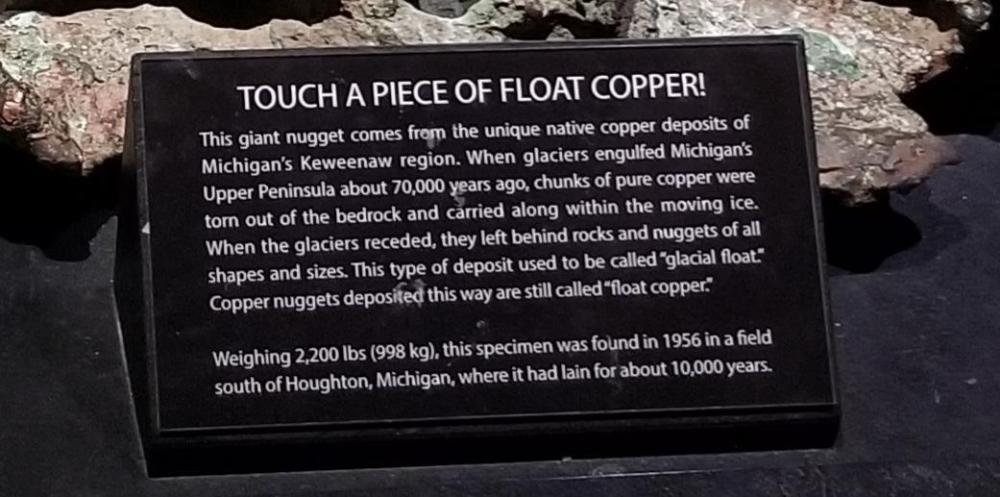

I took my girls the the Carnegie museum of natural history saturday and they had this chunk on display there. Didn't get to see as much as I would have liked but the girls had fun for as long as their attention spans could handle.

-

I mostly use the horn of my anvils as fullers and to true up bottle openers. It allows me to hit the ring at an angle and leave a pretty chunky amount of hammer marks on both the inside and outside of the ring. The only other thing I can think of I've done with a horn in the last few years is weld 12-14" rings on it. Work well for that, before taking that ring to the floor cone. Scrolls, finials, hooks, curves I all do at the edge of the anvil.

-

bestsmmmarket joined the community

-

What did you do in the shop today?

George N. M. replied to Mark Ling's topic in Blacksmithing, General Discussion

Billy, you may have found an ammonite that was buried quickly enough that the ctitter's soft parts were preserved. In life an ammonite looked like a modern nautalus, a squid with its tail stuffed into a shell. Some have straight, cone shaped shell but many have coiled shell, like a snail. Hence the name. The shells are supposed to look like the coiled ram's horns of the Egyptian god Amun/Ammon. I've seen some that are completely replaced by pyrite and have a spectacular gold/brass color. G PS To bad about your geologist ex. MY experience has been that geologists make good partners. -

Definitely a recovering geologist. It's one day at a time and you're never completely cured. Whenever I get an urge to make a map or hit a rock with a hammer I call someone up and they talk me out of it. "Hi, my name is George and I'm a geologist." (applause) "I've gone 27 days without hitting a rock with a hammer." (more applause) Unfortunately, Martha, my late wife, and I were codependent since she was also a geologist (and an attorney). On the other hand it has been an interesting and useful field of expertise. I was hired for a couple of legal jobs which involved regulation of the oil and gas industry because of my geology background. In hearings I was the oil and gas industry's and the invronmenalists' worse nightmare, someone who was advising the legislators who knew about the industry and could see past the smoke and mirrors. "What a long, strange journey it has been." G

-

Tom Burton joined the community

-

What did you do in the shop today?

Florida Man Metals replied to Mark Ling's topic in Blacksmithing, General Discussion

I read a while back that pyrite actually contains nanoparticles of gold in it. More recently I read about lithium being in pyrite. They are looking at it for industrial lithium extraction. -

Well, I completely misunderstood what you wrote, I don't know why, but I did. And I should know better. I would never expect you to turn off caring about people, anymore than I could not care for others. Especially friends. I sincerely appologize for my confusion. I sent you a PM concerning this. You have many thanks for the hug and scritch coming your way...... As far as the bumping thing goes, I bumped a topic TWICE but did not add any content to it. Actually this happened once before, I was warned and it is entirely my fault. Can't have everybody bumping everything all over the place, it would get pretty confusing. My, this thread went haywire.....

.thumb.jpeg.13ce8080353b8d0cb0112c296320d4f5.jpeg)