All Activity

- Past hour

-

AdultAd joined the community

- Today

-

cryptoads12 joined the community

-

What did you do in the shop today?

Davor replied to Mark Ling's topic in Blacksmithing, General Discussion

Something like that, with the handle for steering. But maybe an axle where just the wheels pivot. I think the table will be wobbly if the whole axle pivots even if that would be the easier to make. I'm still thinking about it. -

We have this machine that you input the dimensions of the of part, put parts in the machine, and it uses lasers and within about half second measures all those dimensions and tells you what the measurements are and if they are out of spec are displayed in red. Those instruments are by 1/2's to the hundred thousandth but accurate to the tenth. A lot of parts i run have +/- .0005" tolerance. I am also holding that tolerance on a machine that was designed 100 years ago and run anywhere from 3,000 to 17,000 a shift. Depending on material, size, etc.

-

avamiaa joined the community

-

You're trying to tempt me into finally cleaning and organizing the basement aren't you? It IS tempting, I'd love to get some of my texts dug out and organized. Frosty The Lucky.

-

What did you do in the shop today?

Frosty replied to Mark Ling's topic in Blacksmithing, General Discussion

When you say one set of axles "can rotate," do you mean turn as in left or right so you can steer the cart? Like this? You can see the pivot the front wheel assembly turns on in the picture. By turn I mean the front wheel assembly itself, not the individual wheels. Frosty The Lucky. -

What did you do in the shop today?

Davor replied to Mark Ling's topic in Blacksmithing, General Discussion

I'm either making castors or I'm leaning to some sort of like a wagon stile with basically two axles where one can rotate. -

Is this slag?

Nobody Special replied to Ridgeway Forge Studio's topic in Smelting, Melting, Foundry, and Casting

Sure looks like slag of some type. Are you near a current railroad? You also tend to find thermite slag where they weld rail in, and it looks, well, a lot like that. I used to bring bits of it home from work once in awhile. -

What did you do in the shop today?

Nobody Special replied to Mark Ling's topic in Blacksmithing, General Discussion

It took three times ramming the mold up and 4 hours of time, but after all that, but finally got another good mold and made an attempt at casting a lathe bed. And for all that sweat and tears, I have all this to show for it. Oooh...ah....and then you wait for two hours to open it and see if it came out right. Should know in another 15 minutes-ish. Isn't casting exciting? Now I remember why I switched to forging... I like the wheels, btw. -

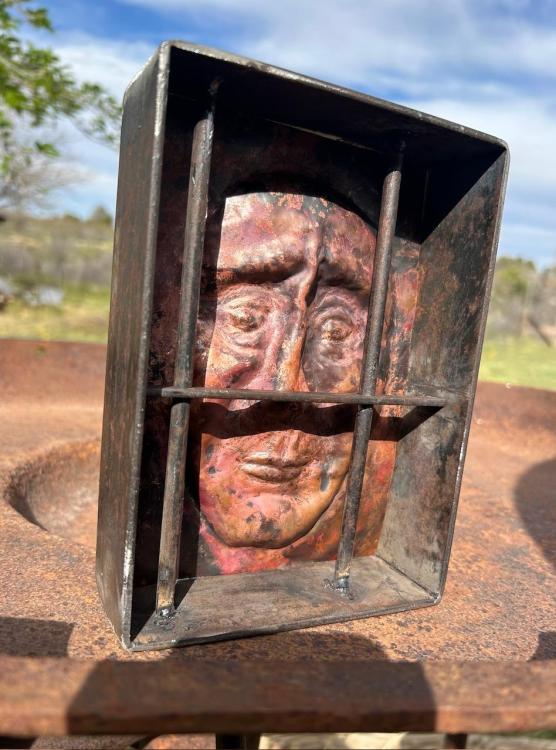

I think the welds fit in fine. I like the patina on the face especially.

-

bgreen776 joined the community

-

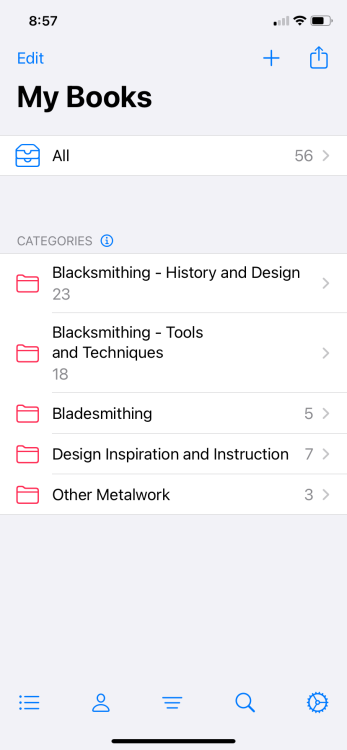

$4.99. There’s a field for “Physical location”, so you could number your boxes and add those numbers to each book’s record.

-

I agree, it does send a sense of longing and loss. Good job. I can't control the wind, all I can do is adjust my sail’s. Semper Paratus

-

That looks interesting. I use Excel on a thumb drive, which I can plug into my phone, however everything has to be entered manually. I can't control the wind, all I can do is adjust my sail’s. Semper Paratus

-

I wish I had something like this a long time ago! I didn't open the link to check the price but I'd have to but into the unlimited version. I don't know if I have the energy to sort through the hundreds of boxes of books in the basement and then organize them so I could locate them. Still it'd sure be nice to know just what I had down there and on the book shelves. Thanks for the link John! Frosty The Lucky.

-

JHCC started following Book Cataloging App

-

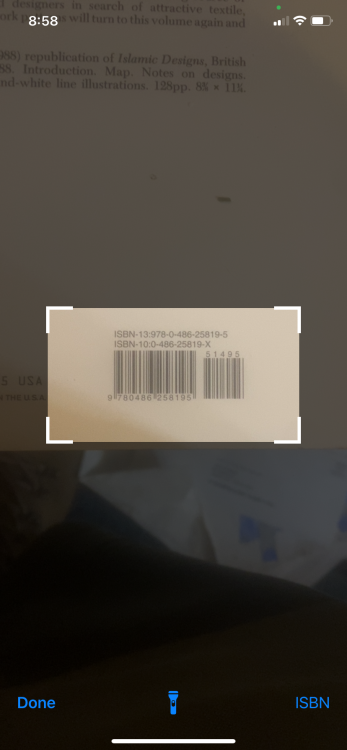

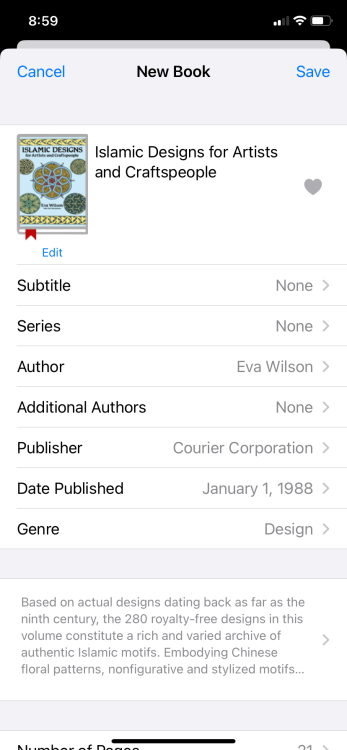

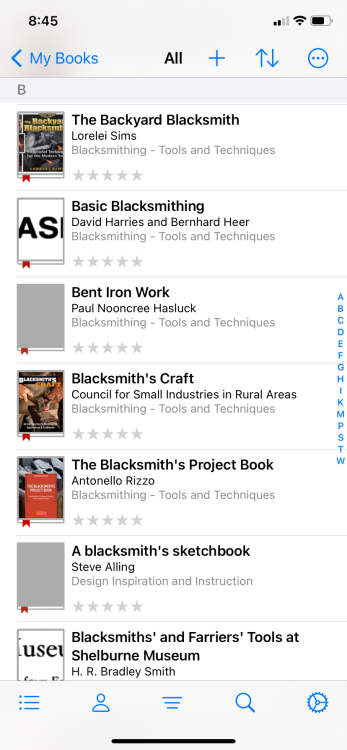

My smithing library has expanded beyond the point where I can remember all of the titles on my shelves. This is occasionally a problem if I’m browsing online or looking in a used book store, and a couple of times, I’ve ended up buying duplicates. In looking for a solution, I discovered a rather good cataloging app called Book Buddy, which comes in a free version and a paid version. These have the same features; the only difference is that the free version has room for a mere 50 volumes, while the paid version (a one-time fee, not a subscription) allows an unlimited number. The features I’ve used most so far are the categorization function, which lets you decide how to organize your books: And the barcode scanner, which lets you quickly identify books by ISBN: Without having to type in all their individual details: For books that don’t have a barcode, you can scan or type in the ISBN, and for older volumes that predate the ISBN system or that were published privately, you can enter the details manually. I haven’t yet tried it with periodicals (such as The Anvil’s Ting or The Hammer’s Blow), but I’ll keep you all posted on how that goes.

-

I have to agree with Larry, your sculpture conveys a sense of sorrow and misery in an attractive way. The rough welds fits the feelings well. I really like it Pedro, I think making the welds pretty would diminish the effect. That's just my opinion, it's your piece you should make it how you like. Frosty The Lucky.

-

I would tack with nickel rod in a few places. Drill and pin in a few places, then grind deep and wide channels around the break. The pins holding alignment. Preheat as much as possible and peen your weld at each pass. Weld all the way around. Wrap in refractory wool and wire it up tight when done welding- to let it cool slow ( nickel rod isn’t terribly sensitive but it doesn’t hurt)then the hard part, grind, file and scrape the sliding surfaces level. I am sure someone here will sugest something better than nickel rod, but it is what I have the most experience with on castings.

-

Is this slag?

Mike BR replied to Ridgeway Forge Studio's topic in Smelting, Melting, Foundry, and Casting

I enjoyed the Hagley (especially the old powder mill) when I was up that way years ago. - Yesterday

-

You've done a nice job capturing what looks to me like worry on the face, well done! Nothing wrong with welds to my eye, seems in keeping with the finish on the steel. --Larry

-

My welding is the worst so I need to clean it up a bit but pretty happy with it. Thanks for looking.

-

What did you do in the shop today?

Mike BR replied to Mark Ling's topic in Blacksmithing, General Discussion

Wheels first doesn't seem that unusual. Just don't put it before the horse. -

Is this slag?

Ridgeway Forge Studio replied to Ridgeway Forge Studio's topic in Smelting, Melting, Foundry, and Casting

That’s not too far away from Longwood Gardens- there’s some nice blacksmithing work in the park, as well as some incredible gardens -

What did you do in the shop today?

Frosty replied to Mark Ling's topic in Blacksmithing, General Discussion

Starting with slices of pipe is so MUCH better than turning the wheel rims manually. Is the cart only for rolling in a straight line or do you have plans for a way to let it turn? Frosty The Lucky. -

You got it Billy, that sort of situation is probably what they're used for most often, another that comes to mind is reproducing antique molding. You use instruments good to a hundred thousandths! Thank you for reminding me I'm more than 50 years out of the biz! Frosty The Lucky.

-

That thing with the pins i have always heard called a contour gauge. It is quite useful in carpentry. Say you are laying floor and there is a pipe or something that you need to fit around. Just push it against the pipe then transfer that "image" to your board and it will fit. Takes a lot of guess work and trial and error out of doing it. Starrett makes quite high quality measuring tools. Just about every set of mics i have ever owned has been Starrett. Brown & Sharp is also a good brand but i have a hard time reading them. All of our digital instruments at work are Mitutoyo. They measure down to .000005".

-

What did you do in the shop today?

Davor replied to Mark Ling's topic in Blacksmithing, General Discussion

I'm going to make a table for the yard, steel base (probably). But I want to be able to move it around. So I made some wheels. Not the most common thing to start with when making a table. -

Is this slag?

JHCC replied to Ridgeway Forge Studio's topic in Smelting, Melting, Foundry, and Casting

While you're at it, check out the Hopewell Furnace National Historical Site: https://www.nps.gov/hofu/index.htm. They've also got a pretty well kitted out blacksmith shop.

.thumb.png.bef4317e3c61450c579cb03452a0c375.png)