All Activity

- Past hour

-

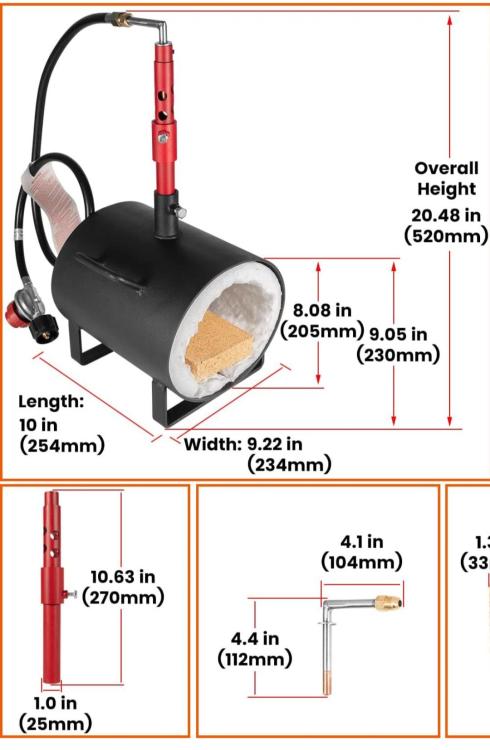

You might want to refigure the volume. As shown I see 283 cu/in volume and if you ad another inch of ceramic wool barely 125 cu/in. The measurements shown are the outside dimensions you have to calculate volume with the inside dimensions. Frosty The Lucky.

- Today

-

delhicg joined the community

-

rachellewisblog joined the community

-

dgr started following Burners 101

-

I do believe I confused the burners I was looking at on AliExpress with the one I pointed you towards. I blame old age. You're right. It isn't copper but it appears to be the same diameter as a mig tip in the photo attached The forge I was looking at with the relevant picture is no longer showing in a search on Amazon. I apologize for the wild goose chase. I wasn't really focused on the forge but the gas tube did catch my eye. The forge and burner is, how did you put it, a garage heater and a good base of parts. If their dimensions are accurate, it could fit another layer of inswool and a refractory coating and end up with about 300 cubic inches. Throw in a decent burner and it might heat some metal.

-

I would guess that is you are adding something new or relevant to the thread that would be OK. But bumping it just for the doing it or for personal gain, like the tail gating section, that would be frowned upon.

-

rubyrise77022 joined the community

-

Casting a Gingery Lathe

Frosty replied to Nobody Special's topic in Smelting, Melting, Foundry, and Casting

That's Way too hot. Did you look up the melting temp of aluminum? 1220f is pure al, casting alloys tend to run lower say 1150f +/- depending on % and alloying metal. You should just be able to see red in a dark room, at orange temps it's oxidizing as soon as it starts to pour and the flux is no longer keeping air off it. 1250f is pushing too hot but should be okay. It isn't filling fast enough, hotter is not the answer. You can see how it was solidifying by the swirl patterns in the casting. You need to improve the flow rate so it fills the cavity before it cools. Aluminum has a low specific heat, it loses temperature fast, the greater the temperature differential the greater the change. That is why making the melt hotter doesn't do any good. You have a flow problem. Look to your runners, gates and fill cup to increase the flow rate. You want the fill cup to gulp the melt, not drain nicely. Frosty The Lucky. -

dgr, I had a look, but did not find any e-cowlboy forge photos of their gas pipe and MIG tip. So, all I have to go on is my own previous experience; that tells me that copper pipe is quite unlikely to be used as a gas tube. A brass gas tube is far more likely. Old brass parts sometimes look like copper in photos. As to how they get a MIG tip with 1/4-27 thread to screw into a 1/4" outside diameter tube or pipe, the gas tube is probably 5/16" outside diameter by 3/16" inside diameter. Although, MK brand MIG tips have smaller diameter thread, which would probably just barely work in a 1/4" gas tube; hey are a superior tip, but I quite using them, because they are just too hard for people to find. By the way, their photos show a lemon yellow incandescent interior, which is consistent with 2000 to 2100 F heat range. 2700 F interiors are white hot. But the worst thing I see about these forges are the exhaust openings and doors. They look nearly guaranteed to warp from the heat of exhaust gasses. I could go on picking out things I don't like about this forge...but, enough said. "Last thing for Mike's new book. I've seen it mentioned in your writing that mufflers are zinc coated. I installed a few mufflers in my younger days and never saw the telltale yellow soot of zinc when welding them. I believe non-stainless modern exhaust components are aluminized and not zinc coated steel." Ups! Suppose I'm showing my age Thanks for the update.

-

Casting a Gingery Lathe

Nobody Special replied to Nobody Special's topic in Smelting, Melting, Foundry, and Casting

For the incandescence, I checked it with the lights off for a couple of seconds, poured at red, not incredibly dark, but not really sure yet if it wanted to go light red to orange. Say about 1400, and I know that's less than 1500...at least in steel, and I spent a long afternoon once hunting down articles on incandescence - what it looked like at the time is that most materials, and certainly metals glow once you get past about 1000 degrees, with about the same color at similar temperatures. Of course, I've slept since then, and I may have read it wrong, and I certainly wouldn't want to trust that as a method in the daylight, but my little laser pyrometer doesn't go nearly that high, and the texture/resistance also felt right. -

Mike, if you get bored, look at an e-cowlboy forge on the jungle. Not because it's anything spectacular but look at the burner. More specifically, the gas jet mount. The pictures aren't great but it looks like they're using a mig tip threaded into a copper pipe that is then threaded into an off the shelf plumbing fitting for the flare connection. What caught my eye is the copper pipe appears to be the same OD as the mig tip. I thought maybe they swaged or soldered it but one of the reviews shows a bunch of swarf that was pulled out of it and the reviewer said he unthreaded both ends to get the swarf out.. My curiosity said, how'd they get a 1/4 diameter mig tip threaded into a 1/4 OD copper pipe? Has anyone looked at the cast iron wasp waisted burners on AliExpress? They're pictures give some ideas. One of them showed compression ferrules on a 6mm gas tube. A 1/4 comoression x NPT might be a slick way to mount an adjustable gas tube. Last thing for Mike's new book. I've seen it mentioned in your writing that mufflers are zinc coated. I installed a few mufflers in my younger days and never saw the telltale yellow soot of zinc when welding them. I believe non-stainless modern exhaust components are aluminized and not zinc coated steel. Cheers

-

That's where I saw it, thanks for the memory jog. I can't control the wind, all I can do is adjust my sail’s. Semper Paratus

-

That's about $165 today.

-

Looks like cast iron to me but malleable cast iron isn't the same as cheap Chinese ASO cast iron. This is all I found regarding the manufacturer and it looks like there were financial issues over quite a bit of it's history. http://vintagemachinery.org/mfgindex/detail.aspx?id=3485&tab=0 I didn't see anything about anvils or other blacksmithing tools or equipment but I'd say from your picture they made anvils at least. Frosty The Lucky.

-

Steel from old garage door springs

PaperPatched replied to Ronin66's topic in Blacksmithing, General Discussion

And if you can tolerate paying more any good hardware store will have new ones. -

Yeah, I was cross checking a 1910 S&R catalogue and the most expensive vise I saw was a $4.97 swivel vise! Keep it fun, David

-

Casting a Gingery Lathe

Frosty replied to Nobody Special's topic in Smelting, Melting, Foundry, and Casting

You're progressing pretty well for not having hands on instruction. when you say you're judging the al temp by incandescence, incandescence of what? Certainly NOT the aluminum, it should barely show color in night time dark. Judge it's readiness to pour by how it feels when you stir it. You DO stir it in the crucible, at least when mixing the flux, yes? Molten aluminum has a distinctive feel when it's the right temp to pour, getting it hotter doesn't help and often makes things much worse. Next time melt at least 50& more than you think you'll need. Weigh the most complete one you've cast and add at least 50% more to the melt. That is why you make ingot molds after all. BECAUSE there is always extra melt and you'd be crazy to let it freeze in the crucible. Yes? Make ingot molds from angle iron in lengths about 1/2 the depth of your crucible. Weld a bunch touching sides between a couple pieces of strap stock. You don't need to weld the ends solid the al will solidify before much can leak through a tight contact fit. Once the ingots are cooled flip it over so it bangs on the ground and the ingots will fall right out. Muffin tins work but pressed steel ones don't last very long but cast iron ones don't take to being banged. Then again I've seen corn bread pan ingots in the shape of little cobs of corn. Soooo. Frosty The Lucky. -

Now there's a thought. Keep a nest or 5 of domesticated packrats behind the back stop at the gun range to collect the jackets, and lead for scrap value. No, I'm not forgetting casing at the firing line but those sweep up of the pavement, it makes for easy clean up of the brass you know. Frosty The Lucky.

-

Casting a Gingery Lathe

Nobody Special replied to Nobody Special's topic in Smelting, Melting, Foundry, and Casting

Some updates - The baked cores for some reason expanded and wouldn't fit in the pattern. Who knew? I made a second attempt and screwed up the pour, which was maybe a bit too cold, and the sprue froze/clogged and I get a huge mess. Third attempt - my ramming has gotten much better, I used incandescence to judge the temperature (at night), I've taken to hand packing the cores into the pattern to avoid flipping it, and I added a touch of bentonite to the sand and tempered it a bit further, which helped tremendously...and then I shorted the crucible by maybe 20 ounces or so...bottom of number two, and the aftermath of number three in the pics below. -

Bingo Scott! It doesn't show in Vintage Vises. A web search for "Halls Sudden Grip Vise" found that very catalogue page. I've read about the type if not these vises before too, if not here then maybe on one of the vintage tool fora. Thomas probably pointed us to it it'd be right up his alley. I lost track of where that thread lives, probably in the bowels of my old laptop. No matter what the computer tech says they never transfer ALL your data. <sigh> That is a great family story Nimrod, thanks for sharing. I ran it by a current inflation calculator and it looks like it cost around $408.66 in 2024 dollars. I hope you find bench space for it at 79' I'm pretty sure it'd enjoy a couple few more generations hammering away on it. I wonder how it'd far here at 4x the elevation? 380' above mean sea level whatever it is at any given second in the Knik Arm of Cook Inlet. Frosty The Lucky.

- Yesterday

-

The US Department of Labor's inflation calculator only goes back to 1913. $14 in 1913 equal $446.19 in March, 2024. So, that vise was definitely an expensive one when new. Cool family story. I don't know if I could tolerate the thickness of the air at 79', particularly when you add the humidity and the heat. I'll stay here up on the hill, thank you. Better thee than me. "By hammer and hand all arts do stand."

-

Nimrod, and to answer Goods question, that catalog is copywrited 1876 (not sure of mfg dates of vises though) and can found on the Internet Archive. Very nice story.

-

Curio's, Curiosities and Artifacts

Irondragon Forge ClayWorks replied to Scott NC's topic in Everything Else

That's probably a pack rat. I once cast about a hundred lead round balls for my 50 cal. muzzleloader's and without thinking, I left them on the bench to cool down and forgot to go back to the shop and box them up until several days later. When I went out to get them about half were gone, found them a month or 2 later in a pack rats nest while digging through stuff on one of my many shelves, looking for something else. I can't control the wind, all I can do is adjust my sail’s. Semper Paratus -

Looks to be cast iron, likely tool steel top plate? Yours is in good condition. its special to have family heirlooms that you get to use!

-

I’d like some help with vise identification.

NimrodPhinney replied to NimrodPhinney's topic in Vises

Scott NC. That looks like you nailed it. Thanks. thanks to all for the replies. For anyone who is interested in its provenance, I can safely say that this vice has been in my family since at least 1879. I’ve done quite a bit of research in my paternal families heritage via ancestry dot com and believe that my 4th Great Grandfather left Kentucky with this vise to St. Louis and in 1880 purchased a pocket watch along with a British Bulldog .44 pistol. (Both of which I have). These three items made it across the plains, thru Colorado and to California then in 1899 to Detroit. The vise was attached to a bench in the city of Detroit where my great grandfather, grandfather father and I would beat the ever loving shit out of it on that bench until I removed it about 20 years ago. It sat on the bottom of my bench until I moved to Florida where it sits on the bottom of a bench. I feel that this vise is considerably older than 1879. so I thank you all from the nose bleed elevation of 79’ above sea level just north of Tampa, Florida. -

I’d like some help with vise identification.

Irondragon Forge ClayWorks replied to NimrodPhinney's topic in Vises

I think it may be here. https://www.vintagevises.com/vise_library.html What's one more rabbit hole to fall down. I can't control the wind, all I can do is adjust my sail’s. Semper Paratus -

When was that published? I was struck by the $14 price. Seems like an expensive type!

-

I’d like some help with vise identification.

Irondragon Forge ClayWorks replied to NimrodPhinney's topic in Vises

Looks like you nailed it Scott, I think I have seen a story about them in another forum, but can't for the life of me can't remember which one. I'll check in my bookmarks to see if I can find it. I can't control the wind, all I can do is adjust my sail’s. Semper Paratus -

Welcome from the Ozark Mountains. It looks like a pretty nice anvil and having the history on it is a plus as far as I'm concerned. I hope you have read about not doing any grinding, milling or welding on the hardened steel face, which will do more harm than good. Hammering hot steel on it will help to shine up the face and help with the roughness. Have you done a ring & rebound test to see if the face is still hard? There is a trick to doing a good search on the forum, put in your search term and add site:iforgeiron.com to the end of the search string. Sadly the search feature on the forum leaves a lot to be desired. I tried that and here is but one hit. https://www.iforgeiron.com/topic/50283-bay-state-anvil/ I can't control the wind, all I can do is adjust my sail’s. Semper Paratus

.thumb.jpg.dffdc87c1637487228f5e63224bed4f3.jpg)