All Activity

- Past hour

-

Welcome aboard from 7500' in SE Wyoming. Glad to have you. As you can tell, there seem to be a higher percentage of veterans on IFI than in the general population. We've got all the wars from Viet Nam on and all branches of the military covered. Yes, blacksmithing is great therapy for whatever ails you. I've been at it since 1977 and it has helped me through the rough times and made the good times better. I recommend it for most everyone. George LTC, US Army (Ret) late of 1/C/1/12 Cav, 1 Cav Div (Air mobile), Republic of Viet Nam, 1970-71

-

I'm just starting in blacksmithing, taking basic classes at Chicago Ave Fire Arts Center in Minneapolis, a tool making class at North House Folk School in Grand Marais, MN, and I've done a number of art welding and metal fabrication classes through the community ed program at the local tech college. I enlisted in the WI Army National Guard on Friday, April 13, 2001. I was a 92Y (unit supply/armorer) in a Combat Engineer Battalion (wheeled). My last name is Riederer (Reed-er-er). I went through Basic Training as "Private Reindeer" - hence the user name. I'm thinking about using it as the business name if I can start to sell products. I was halfway through spring semester of my Junior year in college when I got a phone call during mid-terms week, telling me to report for active duty in 10 days. I lined up outside the registrars office at 7:45 the next morning along with dozens of other reservists, and dropped 18 credits of classes I was acing. My unit mobilized through Ft. McCoy, WI in March 2003. We hit Camp Virginia, Kuwait in May. On my 21st birthday in early June I rode into Iraq behind a machinegun. At the end of the road, right before we turned onto Tallil AB, these Arab guys were yelling "Mister, Mister... Whiskey... Ice... Beer!!!" But we couldn't stop!!!! That isthe kind of stuff that gives a guy from Wisconsin PTSD... screw the mortars and the IEDs. I got out of the Guard in 2007, I did two years with an Army Reserve unit rather than get yanked back from the IRR for another deployment. Got out in 2009 as a newlywed, rather than go to Afghanistan. Now I'm divorced and working for the Army Corps of Engineers as a civilian. I'm learning to pound metal to stay sane and release some creative energy.

-

Reindeer Forge joined the community

- Today

-

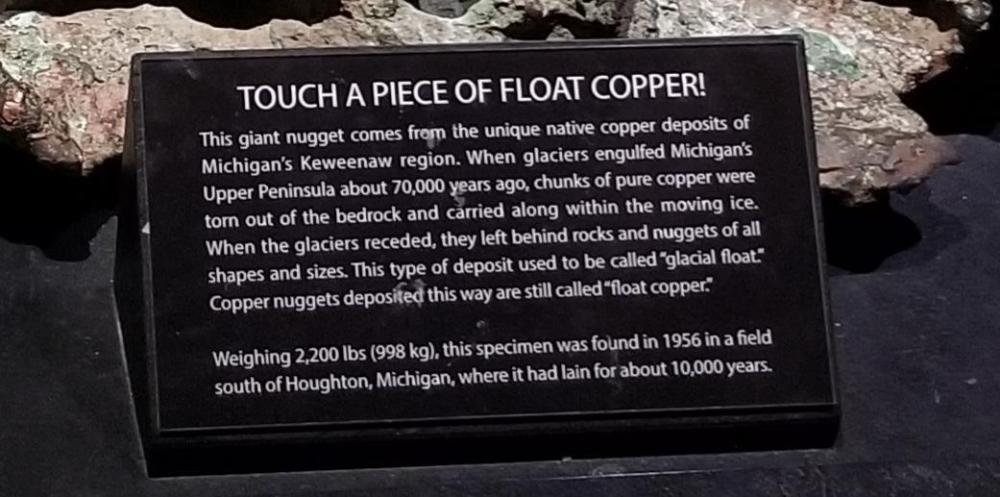

I took my girls the the Carnegie museum of natural history saturday and they had this chunk on display there. Didn't get to see as much as I would have liked but the girls had fun for as long as their attention spans could handle.

-

I mostly use the horn of my anvils as fullers and to true up bottle openers. It allows me to hit the ring at an angle and leave a pretty chunky amount of hammer marks on both the inside and outside of the ring. The only other thing I can think of I've done with a horn in the last few years is weld 12-14" rings on it. Work well for that, before taking that ring to the floor cone. Scrolls, finials, hooks, curves I all do at the edge of the anvil.

-

bestsmmmarket joined the community

-

What did you do in the shop today?

George N. M. replied to Mark Ling's topic in Blacksmithing, General Discussion

Billy, you may have found an ammonite that was buried quickly enough that the ctitter's soft parts were preserved. In life an ammonite looked like a modern nautalus, a squid with its tail stuffed into a shell. Some have straight, cone shaped shell but many have coiled shell, like a snail. Hence the name. The shells are supposed to look like the coiled ram's horns of the Egyptian god Amun/Ammon. I've seen some that are completely replaced by pyrite and have a spectacular gold/brass color. G PS To bad about your geologist ex. MY experience has been that geologists make good partners. -

Definitely a recovering geologist. It's one day at a time and you're never completely cured. Whenever I get an urge to make a map or hit a rock with a hammer I call someone up and they talk me out of it. "Hi, my name is George and I'm a geologist." (applause) "I've gone 27 days without hitting a rock with a hammer." (more applause) Unfortunately, Martha, my late wife, and I were codependent since she was also a geologist (and an attorney). On the other hand it has been an interesting and useful field of expertise. I was hired for a couple of legal jobs which involved regulation of the oil and gas industry because of my geology background. In hearings I was the oil and gas industry's and the invronmenalists' worse nightmare, someone who was advising the legislators who knew about the industry and could see past the smoke and mirrors. "What a long, strange journey it has been." G

-

Tom Burton joined the community

-

What did you do in the shop today?

Florida Man Metals replied to Mark Ling's topic in Blacksmithing, General Discussion

I read a while back that pyrite actually contains nanoparticles of gold in it. More recently I read about lithium being in pyrite. They are looking at it for industrial lithium extraction. -

Excavations at Sheffield Castle

Florida Man Metals replied to Scott NC's topic in Historical Ironwork

I was confused as well and realized I might have committed this fauxpar. The only difference that I could come up with was that he was the one that originally started the initial thread. Correct me if I'm wrong. -

The most useful blacksmithing ideas

Florida Man Metals replied to Glenn's topic in Shop Tips n' Tricks

I appreciate the time you took to research the coal question George. I mainly came to the same conclusion but figured I would ask the right person their opinion. I know you're a recovering geologist so who better than you. Like you said it is murky water when it came to trying to research online. Not to mention throw in the confusion about true coal or charcoal aspect and all the warning to get rid of any bags that have gotten wet only muddied the waters more. -

I am not getting this bump thing, isnt that the same as when some one says they are reviving an old post maybe from years ago? Anyway, am i the only one who read that story in a Monty Python documentary kind of voice?

-

I have used leaf for a few chisels, mostly for wood working though. I made a couple big Bowie knives with leaf a couple years back, of course a few axes, i think i still have a couple unfinished, and the dies for the guillotine as well. I am kind of thinking of using one leaf, the one with the bushings on the ends, and build some sort of ballista. Use the spring for the limbs of a giant crossbow more or less.

-

What did you do in the shop today?

BillyBones replied to Mark Ling's topic in Blacksmithing, General Discussion

Interesting fact i found out, the most mined substance in the world today is sand. My knowledge of what minerals that are around me is rocks and dirt. As a matter of fact that is about what i know about geology at all. Really though around here to find anything of value like that it would be either Indian artifacts like arrow heads, spear points, etc. or fossils. Oaks Quarry park, Frosty knows of it, is about a mile from my house. Someone there a couple years back found a fossil of some kind of tube worm. Now the shells of them are pretty common but this one had the worm's "head" sticking out of it. Looked kind of like palm leaves. It was valued at many thousands of dollars. I have found a lot of what i used to call natalists but i think someone told me they were ammonites iirc. The Indian artifacts that have been found here are really old as well. 500BC old. If you find something you are allowed to keep it but if you sell it you break a few laws. There are ways to sell the stuff but it is not easy. I have found a few semi precious stones, carbuncle, garnet, amethyst, etc. And one piece someone told me was jade but i have my doubts. Being this area i live was were the glaciers stopped, we have a town just south of me called Moraine, it can be a toss up on what you will find. So, thar maybe gold in them thar hills yet. Ohio also has a lot of flint and if pyrite were valued like gold, we would all be rich. I used to live with a girl that was a geologist and here father was a geology professor at an Ivy League school. When she moved in she was the one who told me my water stunk like sulfur becuase there was a vein of pyrite under the house, the bacteria eating the pyrite waste product was what gave it the sulfur smell. She took care of that and as long as we lived there had good water. -

What did you do in the shop today?

George N. M. replied to Mark Ling's topic in Blacksmithing, General Discussion

I had a friend in law school who had previously worked for the Union Pacific Railroad. It was a union shop and you had to belong to a union but it wasn't specified which union. For some reason my friend had a grudge about the regular railroad unions. So, he joined the Industrial Workers of the World (IWW, aka Wooblies) which are still an active organization. That satisfied his union membership requirement. The IWW did have good songs. They say you aren't a real radical unless you know ALL the verses to "The Red Flag." GNM PS Here is a link to the IWW's website: https://www.iww.org/ -

FL Man, I hadn't given spontaneous combustion much thought and I have never heard of it happening on a blacksmith level. I have done some research and it is a murky and complex subject without a lot of clear indications of what to do or not to do. Here are some facts that I have been able to gather, in no particular order: -Some coals are more prone to SC than others. Some coal seams have experienced SC in situ when exposed to atmospheric oxygen. Generally, it seems that lower grade coals such as peat, brown coal, lignite, and sub-bituminous coals which have a higher volitile content are more subject to SC. -The finer the pieces of coal the more chance there is for interaction with atmospheric oxygen and more likelihood of SC. -Larger piles of coal (hundreds or thousands of tons) seem to be more subject to SC because the centers of the piles are more well insulated. It seems to me that in blacksmithing contexts and back when many homes had coal furnaces (amounts of a few tons at maximum) that spontaneous combustion is a pretty low risk but not zero. I have only heard of it happening in the context of large coal storage piles and steam ship coal bunkers (it is probable that the USS Maine blew up in 1898 due to a coal bunker fire overheating an adjacent magazine). I'd like to hear if anyone has any stories of SC occuring in blacksmith or home coal piles. GNM

-

What did you do in the shop today?

Nobody Special replied to Mark Ling's topic in Blacksmithing, General Discussion

I've seen the gold fever. They get crazy. You can pan for it lots of places. I've found a few flecks embedded in rocks here (Whidbey Island) dropped by glaciers when I was hunting for jasper and agates. An Army buddy (the guy that taught me to make moonshine, before he got kicked out for...go figure, DUIs) had a brother that used to pan streams on their land up near Dahlonega, GA. It wasn't worth professionally mining, and he didn't make much, but he could work four hours a day and make a lot more than flipping burgers. Seems like a lot of the really good mines started by people fixated on gold, or sometimes silver. Come for the gold, stay for the tin, mercury, copper, antimony, bismuth, lead...Bisbee got started that way in the 1800s, and they were taking copper out of the ground until the 70s. They also had that whole thing where they rounded up a few thousand men supposedly for being Wobblies and tried to get the Army to put them in a detention camp, but that's this whole other story. -

The most useful blacksmithing ideas

Florida Man Metals replied to Glenn's topic in Shop Tips n' Tricks

Goods you figured out my plan. Hey an asset is an asset. This coal question might be another misnomer like the back flash suppressor that Frosty schooled me on so I thought I would ask. -

Part of what I do in my business is cast iron welding, In my experiance the best way to repair a casting is metal spraying for the most reliable repair but it is expensive as most of the nickle rich processes are like stick welding and metal spray. I would set up the broken pieces as best I can with the smaller part being slightly proud into the bearing surface and set it up so it can be held in position probably by bolting, Then I would take it apart and do a weld prep that allows plenty of acess to the weld area. Then i would use a nickel bronze rod and using a cast iron tinning flux tin or coat the smaller part first to see if it will take a coat of the bronze and do the entire face of the repair. Then reassemble the pices and heat the whole casting up using LPG or a diesel burner after wrapping the whole thing with Koawool or simmilar and heat it up to 4-500 deg cent and tin the second area. Once this has been done then its just fill up the weld prep. When doing the tinning coat if the bronze does not freely flow then the area is not clean enough, not hot enough or not enough flux and any repair where this does not happen you are wasting your time and money proceding. with one of my repairs in the past the cast iron just would not take a tinning coat so I tried a coat using the metal spraying torch then continued with the bronze on that and it was succesful. Their is always more than one way to do a repair and I enjoy the challange of doing repairs no one else will try. after the reair has cooled overnight then the protruding smaller part of the repair could be machined or filed or some by other means back to where it needs to be.

-

No you have a point, I've mostly just used it as a fuller too, though I've only got about 5 years at the anvil. It is quite nice for bottle openers though if you don't have a huge drift.

-

Find mentors, and glean everything you can. (Applies to most skills…) Keep it fun, David

-

The most useful blacksmithing ideas

Florida Man Metals replied to Glenn's topic in Shop Tips n' Tricks

George Do you have to worry about spontaneous combustion due to oxygen absorption from the air? The oxidation causes a hot spot deep in the pile possibly causing it to ignite. I don't deal with coal I use propane in my foundry? Just curious thought this would be the best place to ask others opinion. -

The most useful blacksmithing ideas

Ridgeway Forge Studio replied to Glenn's topic in Shop Tips n' Tricks

George, I paid the price of not being able to get something I loved- Trader Joe’s used to have a seasoning blend called Ajika- it was the best for eggs. But they stopped making it and I haven’t had it in half a year. -

Not the "sole" purpose sometimes. But thanks for reading my mind.

-

The coal advice is true for most everything. If you find something you really like/need, buy two or more because they will stop making it. Buy as much coal as you can afford, haul, and have room to store inside. It will last forever inside. Do not store it out in the weather, water and freeze/thaw cycles will cause it to "slake." That is, break down into smaller and smaller pieces until you just have a pile of black, coarse sand. It will still burn but not as well and the coking ability will probably be reduced. GNM

-

Excavations at Sheffield Castle

Irondragon Forge ClayWorks replied to Scott NC's topic in Historical Ironwork

A "bump" is a post or comment made by someone with the sole purpose of increasing the visibility of the primary message. Moving it to the top of the list. I can't control the wind, all I can do is adjust my sail’s. Semper Paratus -

You are better off that way. I will respond properly when I'm not stuck in the doghouse.