All Activity

- Today

-

Is this slag?

JHCC replied to Ridgeway Forge Studio's topic in Smelting, Melting, Foundry, and Casting

While you're at it, check out the Hopewell Furnace National Historical Site: https://www.nps.gov/hofu/index.htm. They've also got a pretty well kitted out blacksmith shop. -

johna1 joined the community

-

Whoops. I need glasses, I'm blind as a bat sometimes.... I was looking at mine. Sorry about that.

-

madisonclarkblog changed their profile photo

-

madisonclarkblog joined the community

-

That is a pretty cool doo dad.

-

I'm a high school teacher and I was blessed to be able to go on a school tour to Japan during our Easter holidays this year. We visited Nijo Jo castle while in Kyoto and I among all the other hundreds of photos I took on the trip, I snapped a few of these rivets on the outer doors: I love the decorative elements, even on such practical, heavy-duty rivets (about 3/4" diameter). I'm not sure what the larger round pieces are but I believe the floral pattern on them is the Imperial Crest which is a Chrysanthemum. There were no photos allowed inside, unfortunately, but they had examples of (I presume cast) metal crests of the Shogun who originally had the castle built in 1603, and the Imperial Crest from when political rule, and the castle, were handed back to the Emperor in 1867. Thanks for looking! Jono.

-

What did you do in the shop today?

JHCC replied to Mark Ling's topic in Blacksmithing, General Discussion

Found a nice chunk of 1” diameter shaft lurking at the bottom of the pile, so it looks like I’ll be going this route. -

Is this slag?

George N. M. replied to Ridgeway Forge Studio's topic in Smelting, Melting, Foundry, and Casting

Most of the slave states that did not secede (Missouri, Kentucky, Maryland, and Delaware) abolished slavery on their own before the adoption of the 14th Amendment. They saw which way the wind was blowing and although initially the Civil War was mainly about reuniting the Union it gradually became a federal war aim to abolish slavery. Techically, the Emancipation Proclamation only freed those slaves which were in areas controlled by the Confederacy as of January 1, 1863. Legally, it did not affect the states that did not secede or those areas of the Confederate States which were under Union control as of that date. In actual practice, slavery pretty much became a dead letter any where Union Armies had control at that time, e.g. much of Tennessee, southern Louisiana, coastal enclaves along the Atlantic coast, and parts of northern Virginia. As the Union GNM -

Which video? The one I watched made perfect sense but there are a number out there. Frosty The Lucky.

-

Is this slag?

Frosty replied to Ridgeway Forge Studio's topic in Smelting, Melting, Foundry, and Casting

When we start snow birding in the RV I'm sure we'll both keep our online friends up on where we're going. I'll be checking IFI when we're near wifi and I'll be my usual talky self so suppose everybody on the planet will know about where we are headed. All we'd need is room to park a small RV and we're golden. Frosty The Lucky. - Yesterday

-

Is this slag?

Ridgeway Forge Studio replied to Ridgeway Forge Studio's topic in Smelting, Melting, Foundry, and Casting

When you make it down this way, stop by! The Mrs and I have plenty of space! George, thanks for that information. I wasn’t aware of the reasons behind the legality of slavery in union states. The Slag may have been used as road fill- there is an old path that leads over the mountain from a failed ski resort construction project…. -

I really think the video is wrong.

-

Hobbieism, hobbielity, dishobbility? . . . Uh . . . Hobbangley, Hobbangler? One of the how to videos shows it being used on H beam and that just works the one 90 angle so I imagine using it on angle iron would be the same. Better exercise a LITTLE control, I'm probably playing HOB with the mods. Frosty The Lucky.

-

Perhaps somebody on the world wide web will... Can you figure out how to adapt it to angle iron... Looking at that video, I think the narraration got it backwards.

-

Hobby, hobbier, hobbiest…. (Not to mention hobbits.)

-

That would be handy alright, bummer I don't work with pipe more I'd have to get one. Frosty The Lucky.

-

I will say these are pretty handy too. I know this is fabrication stuff but I think it's all tools to use. The dial is adjustable. Same company.

-

Oh MAN, I'm a hobbiest, should I be sorry too? Thanks for the video, I remember the things now but that was in high school. All we did in the welding school was run bead and study the book and that was to earn my pipe and structural cert! Frosty The Lucky.

-

I guess I think small sometimes. I am a hobbiest. Sorry.

-

Is this slag?

Frosty replied to Ridgeway Forge Studio's topic in Smelting, Melting, Foundry, and Casting

ANOTHER place for the bucket list! I want to see Sturbridge too, guess we'll be close enough to see both and whatever's in between. Frosty The Lucky. -

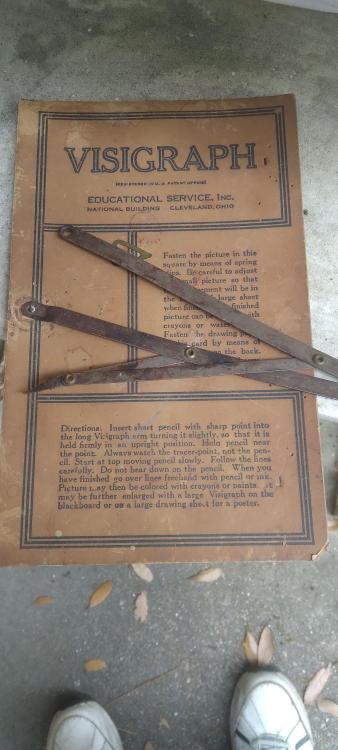

Dad had one clamped to his drafting board, like a modern drafting arm. He kept it locked so I wouldn't mess with it WHILE I was practicing my drafting. He insisted I knew how to draw and read prints. Another home run Dad! Frosty The Lucky.

-

Okay, I'm unfamiliar with the contour marker in the top right of the gold pans but I found pics online. Don't have one of those, how's it work? I would've had to jack the mobile home at least 5' off the ground to slip the small lathe under it and lay the mill on it's side. Uh, I got Dad's plan turned around, he didn't want me to become a metal spinner? Or it WAS his plan and I swum upstream? Frosty The Lucky.

-

No, that pin thing is not the curve-o-mark countour marker. I mainly asked that as the pin one was new to me. I would buy those machine tools and slip them under the trailer. If I had the sheckles at the time. There's an old fellow that has a second hand shop near me that reminds me of him. He is nearly deaf and we have to yell at each other. He's touchey too.

-

That was the original plan, but you got turned around.

-

Somebody mentioned a pantograph recently and here's something I came across today while unboxing (still). I knew I had it but forgot. It is attached to the board with a copper washer and rivit. No clam shell packaging.

-

Yes, that's the one I was referring to, mine is about 2x as wide and cost a bunch new, I got mine at a shop liquidation sale along with a wraparound and more. I got to shooting the breeze with the old fellow who was holding a retirement sale. Neither of his kids wanted to get into the business so he was selling it off and going to Europe with the missus. We got to talking and he threw in a bunch of other things gratis I could've bought a lathe or mill for scrap if I hadn't lived in a mobile home in S. Mountain View. He was royally ticked at his sons. I understand their point of view, I certainly didn't want to become a metal spinner after spending the 1st. 17 years of my life working in a spinning shop. Frosty The Lucky.

-

Is this slag?

George N. M. replied to Ridgeway Forge Studio's topic in Smelting, Melting, Foundry, and Casting

Almost certainly slag. The vesicles (bubbles), the shiney black surface, and the sharp edges on the face nearest the camera indicate a high silica (glassy) slag. Slag was used for a lot of things including fill for canal and railroad embankments but often only when transportation costs made it cheap because it was inferior to natural rock or gravel. It was lower quality because it was more brittle in use and would break up more easily than natural rock and was also lighter in weight which meant the fill could shift more easily. Like Frosty says, it could have just fallen off a wagon. "By hammer and hand all arts do stand." Because Maryland was not in rebellion slavery in that state was unaffected by the Emancipation Proclamation. Slavery in Maryland was abolished by a new state Constitution effective November 1, 1864. Surprisingly enough Delaware was also a slave state in the 1860s. Maryland had 87,189 slaves in the 1860 census, about 12.6% of the total population. Here is a link that gives the breakdown by county: http://slavery.msa.maryland.gov/html/research/census1860.html Interestingly enough, the Black population of Maryland in 2020 was about the same percentage as slaves in 1860. GNM