100_2170.jpg

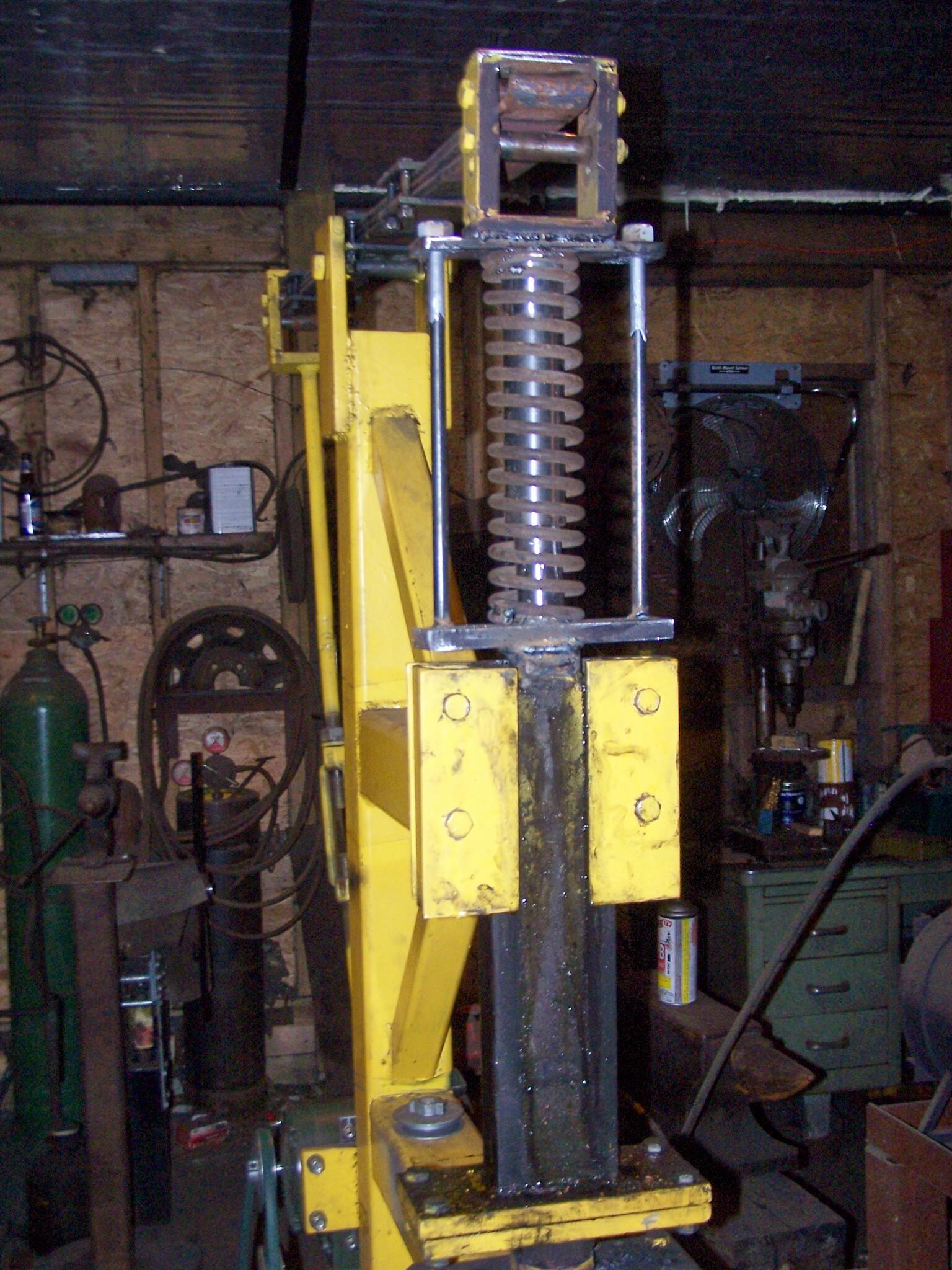

I removed the solid tubing as the connecting rod and made this with a coil spring over a round tube which is over a solid round . This way the spring can compress and allow the hammer to make a full revolution more easily and stressing the motor less.

Recommended Comments

Please sign in to comment

You will be able to leave a comment after signing in

Sign In Now