-

Posts

99 -

Joined

-

Last visited

Contact Methods

-

Website URL

http://jackkewitz@gmail.com

Profile Information

-

Gender

Male

-

Location

South Chicago suburbs

-

Interests

Art, Mysticism, The Occult, Psychedelic Phenomena, Cultural Anthropology, Mythology.

Recent Profile Visitors

4,353 profile views

-

They said it's a "venturi" type. You guys are right, it moves. It has only 2 holds. Not 3 like the burner holds. The holds grab the parallel sides of a hex bolt nozzle. It's easy the straighten but also easy to fall off center. It swings kinda. Should I tap in 2 more holds? Also, should I be wary of possible zinc on those bolts holding the flange? Vapors and such. Thanks guys Luckily they're soft brick!

-

Mikey98118, Frosty Better? I made the top removable for when the interior needs fixing. I'll be happy if it lasts till autumn. I don't forge as often as I'd like. Weekend warrior... Anyway, It's got a half inch of refractory on the brick. First gas forge. Hopefully when it crumbles I'll have kaowool for it. I'll post it in action when I get a chance.

-

Good idea Thomas. I think I'll make a screen shovel.

-

My Charcoal maker

Jack-O-Lantern replied to ronwend523's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Thanks for the info. I might try it. -

Noooo!!! I've been frost bit! It's not done yet Frosty! Being mean is fine. I just wanna know what to do. The tape is rated for gas. I haven't committed to the shape yet, that why the bricks not sealed with refractory yet. Thanks for tip about burner placement. I've read through 17 gas forge threads and none mentioned burner placement. I DID however find you mention the "peanut butter" consistency of certain types of refractory. The tops not cubed yet because of my burner query. All I got is steel, firebrick, and refractory. I've seen others use the same materials successfully. I'm trying to work with what I got. If I could I'd have a steel shell, insulation, refractory, a hard pizza oven type tile for the work piece, and even ITC 100. I've read all about that stuff here, but alas, I don't have access. Floor flange it is. Thanks. I ordered the burner because making one is way over my head.

-

They make a v shape that collects burning coal from the wood fire. The coal collects in the valley as the wood burns. If the fire is more spread out in the larger firepot shape; then the hottest coals in the bottom spread out. The v helps collect and concentrate the hot coals via gravity. I'd make charcoal if I could. I'm totally copying a design. I've tried it with flag stone in a bon fire with a horizontal pipe with holes drilled in it. It works. I made this The same v shape with charcoal heated a 1 1/4" inch piece faster than just burning charcoal in a fire pot. It used alot less fuel as well. If I could I'd bring my bonfire closer to my anvil but, it's about a 70 foot walk. Maybe I could use a cheapo fire pit on wheels. Hmmm....... Cool. I thought they would be too small. The v goes down the the clinker breaker. So I think it'll work...I hope it will work. If it does I'll post results. The v design helped manage charcoal really well. It also used way less.

-

Has anybody tried this? Thin menards Firebrick cut to shape. They're in a centaur forge coal firepot. I wanna use the v shape as a wood forge. I chopped up some 1" thick branches into 3" or so long pieces. I'm out of coal so I thought I'd give this a shot. I've used a trench in a firepit with big branches, but never small wood chunks in a coal forge. I'll let you guys know how it turns out.

-

My Charcoal maker

Jack-O-Lantern replied to ronwend523's topic in Solid Fuels: Coal, Coke, Charcoal, Wood, etc

Cool man. I wish I had one. You could probably sell those. Especially if it's as user friendly as it looks. Nice work. -

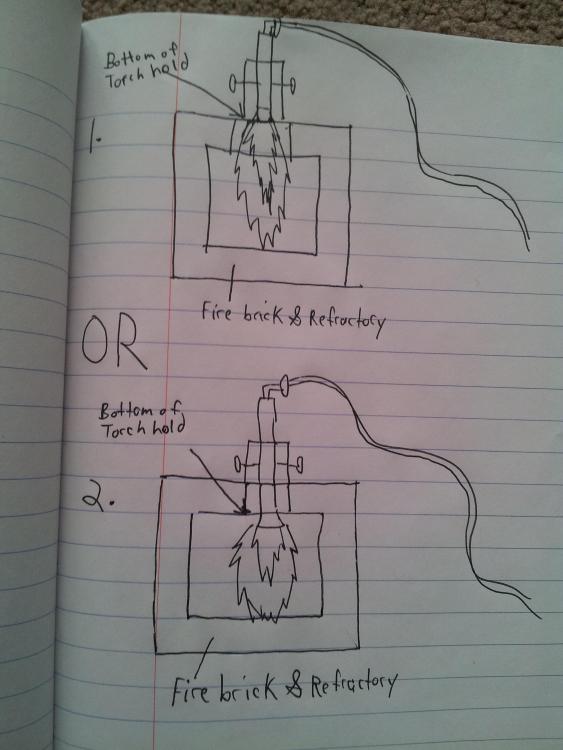

Hey guys. So I ordered a venturi burner from Mathewson Metals via Ebay. I used blue monster thread tape for the threads that fit the hose. I read yellow tape is for gas but this stuff says it's for gas, and is gummier and thicker than the white plumbers tape. So it's good right? I'm attempting to build a forge body for it now. Its gonna be fire brick and refractory in an angle iron cube. The brick is thin, and rated 2400 fh. The refractory is the premade type. Not castable. It is for the interior, as I've read here is proper. It's rated 3000 fh. This is the body so far. It's taller than it is wide by about 1/4". I wanted it high for the flame to have space. Should I correct this before I put on refractory? The opening as of now (pre-refractory) is 6 3/4" high by 6 1/2 wide. I plan on adding a half inch or more of refractory. I decided to put the burner up top for 2 reasons. 1. Angling the burner hold is a bit out of my league as far as fabrication goes. 2. Though the even heat of a swirl sounds good, I think a hot spot will be more useful personally since I'm not a knife maker. So should the burner hold bottom be flush with inside, or outside of the forge "shell"? Is it 1 or 2? And should the torch head come out a bit? All replies are appreciated. Also, propanes kinda scary to me. Any tips welcome. I've never tried it but from what you guys say, it's a huge time saver. And $ saver for me in the burbs outside Chicago. We'll see. I'm just sick of clinkers, soot, and smoke. The startup time of coal, and missing out on rainy days. I'll post updates after you wizards show me what to do, and I do it. Thanks for looking.

-

This is awesome. Do a mural on sheet metal. Try cutting strips of the stem for a higher concentration. Or just for laying out patterns or anything else you can think of. How long was the flower pressed on for? Or was it just laid on the metal?

-

Alright homies. Apologies for the generalizations. Lemme rephrase my question. Which kind of forge will heat raw wood fuel more efficiently based solely on it's material components? A washtub forge, or a Whitlox forge? Or is the heating economical efficiency the same by virtue of the v shape of both types? As well as the same air input method via a verticle pipe with holes. I'm choosing one or the other, and if a washtub forge handles raw wood fuel as well as a whitlox does; Then I'm making a washtub forge. Why pay 150$ (to whitlox) for something that works just as well as something (a washtub forge) that will cost considerably less?

-

Cool Glenn. I was basically wondering if the refractory would have a sponge effect. As opposed to thin kaowool under fire brick giving the heat no where to soak in. I know open forges don't keep heat in, but I want as little absorbtion via the sides as possible. Raw wood is my best option for fuel so I want it done right. Plus the $ factor makes me wanna do it once. I can't afford to go back to the drawing board.

-

I'm talking about radiant heat on the sides of the forge. The kaowool route will be like the whitlox: 11 gauge v, kaowool, firebrick. The washtub route is: refractory, firebrick. Maybe a bucket sized lump of refractory cast as a v, lined with the brick. Won't the refractory absorb more heat than the thin kaowool?I've never worked with raw wood and my milk moneys on the line! I gotta ask Frosty!

-

@JMR There's a place called "Ephram Forge" in Frankfort, and "The cutting edge", in Oswego." And...... Lawndale Forge-Lawndale Kropp Forge-Cicero J.Gilbert & Co-Humboldt Park Custom Iron Works- Northlake Schulte Studios-Sugar Grove Anvil Arts and Design-Newark Charles Larson and Sons-Belmont Gardens Mitchel and Mitchel-Way up by Irving Park I think Me-??? Good luck der guy!

-

What up guys!? Long time no post. How are you tuff cookies? I've missed ya. Aside from playing in the strange corners of the inet; I've learned alot about smithing since my last visit. But not enough! So here goes: Does refractory (or mud, clay, plaster of paris with sand, etc. etc.) insulate heat as well as kaowool? I ask because I want to make a wood burning forge similar to the whitlox model. They use kaowool and it keeps the heat in well enough for people to report good forging temps. As we all know clay is free, and kaowool is not. So will something like the wash tub forge hold heat in enough for raw wood fuel to get hot enough? Or should I spring for kaowool? I am going to order the whitlox mini forge hood. So it will help either way, but I wanna know what's better. Thanks guys and gals