-

Posts

11 -

Joined

-

Last visited

-

Majestic Forge vs. Chili Forge - Decisions for a Newbie

mtodriscoll replied to Kexel Werkstatt's topic in Gas Forges

The forge I use now is a coal forge built from an old gas grill body/cart. It works, but I'm ready for a cleaner fuel source and something that doesn't burn your steel up if you look away for a second. -

Majestic Forge vs. Chili Forge - Decisions for a Newbie

mtodriscoll replied to Kexel Werkstatt's topic in Gas Forges

Thanks for the post Kexel! Interestingly enough, those were the two brands/models of forge I was narrowing down to after doing some research. The Majestic Forge has the "As Seen On TV" (Forged In Fire) advertising going for it! But, if you've ever watched that show, you will see tons of dragon's breath billowing out of those forges and contestants go down fairly often with heat-related health issues. The more I researched, I had to remind myself that "Forged In Fire" has deeeep pockets for buying as much Propane as they need to run the show; whereas I do not. So...I struck that one from my list. The Chili Habanero forge had risen to the top of my list and I was close to pulling the trigger. Then I came here... As I learned more on this site, especially regarding ribbon burners, I decided to try my hand at building my own forge and burner. Materials to build my own will only be about 10-20% of the cost of a Chili forge (not including my time), so if the experiment doesn't pan out, I'm not out a ton of money. Plus I'm not in a huge hurry as I have some coal I need to use up in the meantime. Keep us updated on how the Chili forge experience works for you! - Matt -

Frosty, Ahhh that explains why I'm not finding any. Thomas, Yes, I've been to his site and looked at his plans. Currently they are worded for use of a Venturi style burner blowing down from TDC. I'm planning to build/to use a ribbon burner that is offset more tangentially. Maybe once I've made mine I'll post some plans with materials list, dimensions, drawings, etc.

-

I've read several references on this site to 'Peer Reviewed Forge Plans' or 'Forge Plans' that can be found somewhere on this site. I've read the majority of this Forge 101 and have learned a lot, but typically it seems someone will post a picture of their forge (or forge idea), then there will be several replies/comments on what is right/wrong about the pictured forge. I have yet to see any "plans" (i.e. material list, dimensions, diagrams, etc.). Maybe I'm looking in the wrong place? Is there a Downloads section where those plans/files are stored, or are the "plans" interspersed among 64 pages of comments in this Forge 101 forum? I see there is a 'Downloads' menu up top, but there appears to only have a few entries in the three categories of Books, Newsletters and Trade Journals. Would be nice to have a 'Plans' category with peer-reviewed Forge and Burner plans available for download... Just an idea. Matt

-

Propane Ribbon Burner forge plans - Comments?

mtodriscoll replied to mtodriscoll's topic in Gas Forges

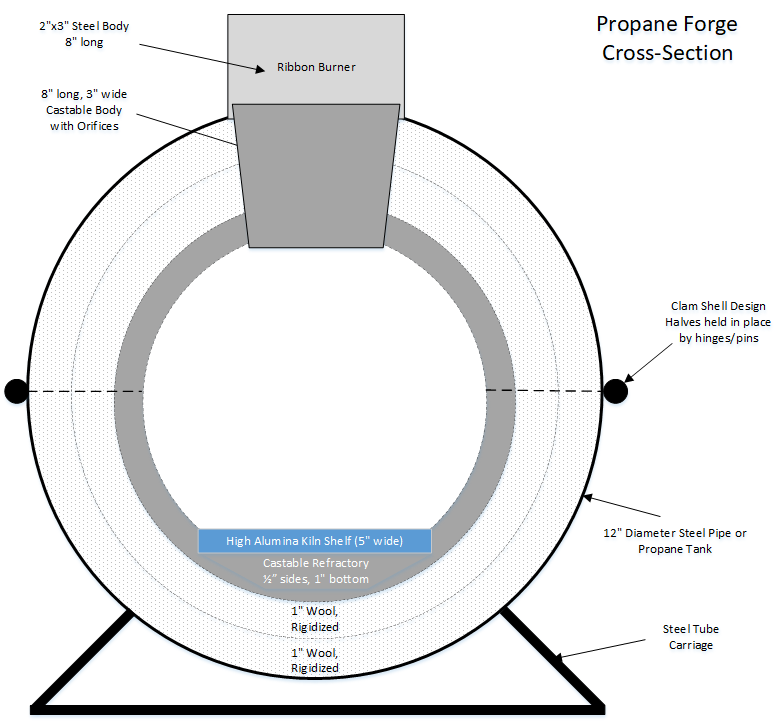

Frosty, Thanks for the tips. Good to know the castable liner can be thinner. I like the idea of angling the end-holes in the burner away from the openings. The clam shell idea was strictly for initial assembly and future maintenance! Although, with all the extra cutting and hinges/pins, it might be just as quick and easy to leave it whole - especially when using an easily replaceable kiln shelf. I'll take another look through the Forges 101 section for doors/plans to compare notes. Tons of posts on this site, and some very old, so hard to know if you're seeing the "latest and greatest" when it comes to advice and plans. Lots of trial and error in these types of builds. Thanks, Matt -

I've been thinking of buying a pre-made forge online, but then after reading through the forge building stickies here, I decided to build my own. Hobby-level use consisting of some blacksmith tool manufacturing (tongs, punches, etc.), some hunting/kitchen knives, and some metal artwork. Some day I'd like to try my hand at damascus billet, but that will likely be down the road. I drew up some plans based on what I read here, and some preferences I had. Fuel source will be propane, and I plan to build a forced-air ribbon burner. See attached picture which shows a cross-section view. I'm still in the early design stages, and am giving the doors some thought... I'm thinking of splitting the body in half (clam-shell design) to make it easier to apply castable refractory, and to make future maintenance easier. 2 layers of 1" insulating thermal wool, each layer rigidized. Inside covered in a 1/2" layer of castable refractory. Floor will have 1" of castable refractory with a high alumina kiln shelf sitting on the floor. Tapered ribbon burner at TDC of body (I'm open to suggestions on placement - just at the drawing stage at this point.) Inside clearance at widest point will be 7". Clearance from ribbon burner to floor seems to be coming in at 6" (assuming a 1/2" shelf thickness). The plans are calling for an 8" long burner, but to be honest, I just made that number up. If I use a propane tank as the body, the floor of the forge may only be about 9" long, so that burner length would be overkill. If I get some steel pipe from the local scrap metal business, I can make the forge floor longer (12"?) and an 8" burner may make more sense. But then I might be making a forge that is much larger/longer than I need it to be for my uses... Some questions: For forges made from 20lb. propane bottles, how deep is the usable floor space in the forge? (9"?) How long should the ribbon burner be compared to the forge's depth? Where can I find high alumina kiln shelf that is only 5"-6" wide? Most places online seem to sell them in 10.5" and wider. Can they be cut? I plan to support members on this site by purchasing my insulating materials here. If someone offers kiln shelf, let me me know! The pages here seem to only sell refractory, wool, rigidizer, coatings, etc. Any feedback/suggestions on my design are much appreciated! Thanks, Matt

-

ACME Anvil Markings to ID

mtodriscoll replied to mtodriscoll's topic in Anvils, Swage Blocks, and Mandrels

I am now the proud owner of the pictured anvil! I was able to talk the seller down from $600 to $350! I live in Virginia and the anvil was in northern NY near some relatives of mine, so I had my Uncle stop in and do a ball bearing test. It had good rebound (about 80%) so he picked it up for me. I should see it in a couple weeks. Maybe by then I'll have my coal forge ready to go and I hammer out my first project. Thanks for your help and advice! -

Close to the same day!

mtodriscoll replied to Black Frog's topic in Anvils, Swage Blocks, and Mandrels

I'm curious what your process is for cleaning up an Anvil? I'm considering purchasing one soon and can guess what I would do to clean it up, but want to make sure I don't do something that might cause harm. Did you just use a wire brush and water? Do you rub it down with mineral oil afterwards to prevent rust? Just curious... Thanks, Matt -

ACME Anvil Markings to ID

mtodriscoll replied to mtodriscoll's topic in Anvils, Swage Blocks, and Mandrels

Thanks for the quick reply and helpful information! I'll see if I can talk them down to something more reasonable in price. If they won't budge, then I'll keep looking. Matt -

Recently joned the forum, and figured I would start posting. Attached are pictures of an ACME Anvil I saw for sale on Craigslist recently. There are quite a few numbers stamped at the foot of the base, see picture. It appears to be stamped '120' on the left. Perhaps the right side is a serial number? (A38215 ??). For ACME anvils, is the 120 indicating pounds, or is that marking the stone weight? (which would make it 168 lbs). In the picture of the side, is the top plate delaminating, or is the top plate seam just visible? They are asking $600 - which seems a little steep given the condition. I was considering offering $350 for it (about $2/lb.), but that is well below the asking price. Is this anvil worth buying for my first anvil? If so, any thoughts on a fair price? Thanks, Matt O'Driscoll Virginia