K A Willey

Members-

Posts

99 -

Joined

-

Last visited

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Beaudry power hammer

K A Willey replied to Simm367's topic in Power Hammers, Treadle Hammers, Olivers

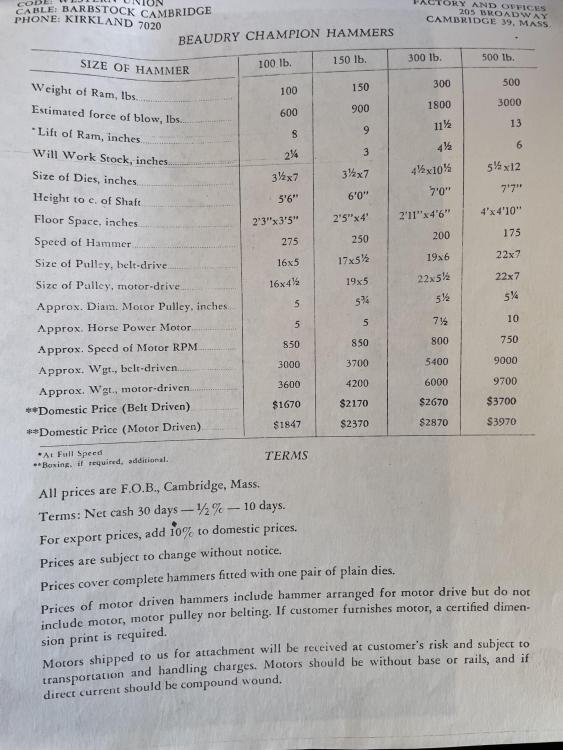

I usually put 5 hp 3ph 900 rpm motors on motor driven clutch model 100# Beaudry champions. Are you going to use 3ph power ? Here is a factory Sheet for your hammer 5 hp 850 rpm usually 3ph was recommended the hammers never came with a motor unless customer shipped them a motor. paper is from 1943 hope it helps -

beaudry hammer roller track repair

K A Willey replied to OneAcre's topic in Power Hammers, Treadle Hammers, Olivers

One Acre your ram could have possibly cracked at one time and the plates were the fix and counter weight to balance as you described (possibly) I have seen that a number of times and have made similar repairs when needed, the hammer was a 200# model when built. -

beaudry hammer roller track repair

K A Willey replied to OneAcre's topic in Power Hammers, Treadle Hammers, Olivers

I’ve resurfaced a few padded them up with dualshied on a couple and 7018 on a couple bigger ones and super missle on one I wasn’t sure bout that looked like it had been welded on before, ( that one was kinda spendy) I found though it is kind of a waste of time unless your ram is cracked the ram is not hard yet should be pre and post heated to minimize distortion to the ram and if a lot of welding is required should be clamped to a fixture plate and post heated for a few days with the fixture plate depending on the size of the ram ( your hammer looks like a 200, what is the casting #s on the spring box ?they are right under the wedge boss in the center of the spring box on bigger hammers like yours ) unless you have enough meat which most of them do and can mill the surfaces back true and re groove the lube channels. Unless the tracks are excessively deep like a 1/2 or more I would not waste my time there is a lot of meat in most of the rams and you will be fine feathering the ridges out if that is the case with your hammer , these are just my experiences don’t mean there right. -

Waiting on warmer weather

K A Willey replied to marcusb's topic in Power Hammers, Treadle Hammers, Olivers

Sweetness -

Krush, not and odd duck, your hammer is likely a 75 I have a #2 the ram weighs 86 pounds and have weighed quite a few # 2 the same, it was probably built that way as a 75 the later Beaudry & Co 50s and 75s used the same one piece frames marked # 2, Beaudry as with many other hammer makers of the time made alot of hammers tailored to their customers needs. Look at the end of the crank it may be stamped 75 if the serial # is in the right range, what is the serial #? Salem that Chart was of early hammers the later hammers were not the same there were alot of differences over the year those hammers were made by the end of manufacture there were only 4 models of the champion made , most 9's are close to 300 lb most the specs on that chart are rough casting not machined yet.

-

Marcus,That will be a beast when you get power to it did you get the info and names I sent you?

-

-

Doyle, Looks like it is working correctly to me.

-

Mechanical hammer brake adjustment

K A Willey replied to beaudry's topic in Power Hammers, Treadle Hammers, Olivers

Sanderson Iron, Beaudrys are like your Hackney, hollow frame and solid anvil, except for the utility hammers they made. -

Mechanical hammer brake adjustment

K A Willey replied to beaudry's topic in Power Hammers, Treadle Hammers, Olivers

I am in northern Wyo, Little giant made a cast to cast clutch for a few years also, not to many of them left' IMO they were their best clutch. -

Mechanical hammer brake adjustment

K A Willey replied to beaudry's topic in Power Hammers, Treadle Hammers, Olivers

Mr. Sanderson Beautiful hammer and thank you greatly for the pictures and your comments on my hammers, very few of the Hackneys around, would love to come to your shop some day, like your bolster die I have a similar on my Little Giant for making rivits. My #7 Beaudry is a cast to cast clutch as well has excellent control when tuned right can deliver a very light blow or really fast single blow. one really nice thing I like with my Beaudrys is the ability to have a very fast penetrative blow on thin stock and move quickly by shorting the stroke it allows me to run 225rpm on a 200 lb hammer, very effective for some types of forging. my 75 will run 350 it is amazing the difference you can achieve on forging times on thinner stock over a airhammer or press, they all have there place don't get me wrong just my hammers are the most versitale for the work I do, thanks again for taking the time to post the pics. -

Mechanical hammer brake adjustment

K A Willey replied to beaudry's topic in Power Hammers, Treadle Hammers, Olivers

Most hammers do stop when you let off the treadle, it all depends on the work you are doing IMO -

Mechanical hammer brake adjustment

K A Willey replied to beaudry's topic in Power Hammers, Treadle Hammers, Olivers

Beaudry, My slackbelts have drain tubes on the back of the crank bearing not all of them have it most the later slack belts do never have seen it on a clutch model the clear tubing put on the brass drain pipe to divert the oil into a container. -

Mechanical hammer brake adjustment

K A Willey replied to beaudry's topic in Power Hammers, Treadle Hammers, Olivers

Here are a few pics of my Beaudrys brakes 2 are slack belt models and one is a clutch, the brake arm depresses the brake as you step on the treadle as the clutch or the idler arm engages the belt, as you let off the treadle the brake arm pushes the brake up to make contact with the pulley on the slack belts and the spider on the clutch model, it is adjusted by means of the big set screw and lock nut on the bottom of the brake box. they work extremely well when adjusted properly and will stop the 200lb ram anywhere on its stroke works very well to push punches into a bolster block and the 75 will stop very rapidly to do singles, doubles or what ever you want, very nice for spring swage work. My 25 has a small shoe on the treadle linkage that just drags on the edge of the flywheel alittle when feathering in the clutch and lets me stop the hammer on the upstroke other than that I have no real use for a brake on that hammer as I want the very rapid blows it delivers on light and thin work hope the pics show them clear enough.