hawk18

Members-

Posts

46 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Southern Orygun

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

The small face shows signs of being used as an anvil. Based on visual inspection, hardness and rebound, I think it is unhardened cast steel. The opposing holes in the rim pass through. The other two rim holes and the one in the small face are blind. There are no identification marks to be found. Given that this is the PNW, there used to be a mill on most street corners and odd looking anvils I’ve seen are often used for tensioning saw blades. This may be another one. Any info or guesses are welcome. CPH

-

What did you do in the shop today?

hawk18 replied to Mark Ling's topic in Blacksmithing, General Discussion

It’s not what I did IN the shop. It’s what I did TO the shop. I moved my tools from the front driveway to a spot in the back yard. Now I don’t have to move my truck and trailer to be able to drag my tools out for use. Then, put everything back. Hawk -

I made the rounds of a few garage sales today and considered my day a success. I found a gold mine of scrap. Actually, a steel mine of scrap. The tool on top is an A 5 Cutdevil rail cutter. Doesn't appear to have been used. The chunk beneath is my new striking anvil. 4.2" X 12.75" X 18.44" calculates out to 280lbs. Gonna take some doin' to get it off the trailer and into the back yard. Hawk

-

Also, a not so fruitful garage sale haul, I ended up with a couple of pieces of bar/round stock. One 5/8” x 7’ and one 1” x 66”. Wouldn’t be so bad but they are SS and also mystery steel. Give me some ideas on what they might be used for. Hawk

-

This was a pleasing mornings haul at a garage sale. The bench anvil is a little rough, but, usable. The bick was rough also and won't fit either of my hardy holes but I'll use it in the vise. Hopefully it won't be too tall. The top fuller and tin smiths hammer were in a box labeled "old hammers, 25cents". The hewing axe was abused but salvageable, stamped J.James & Son, Detroit, No. 6. Can't find any info on it. Got the whole bunch for $20 and he threw in an old oil pump can that is brass tagged from the S.S. Caledonia. Interesting read on Google. Hawk

-

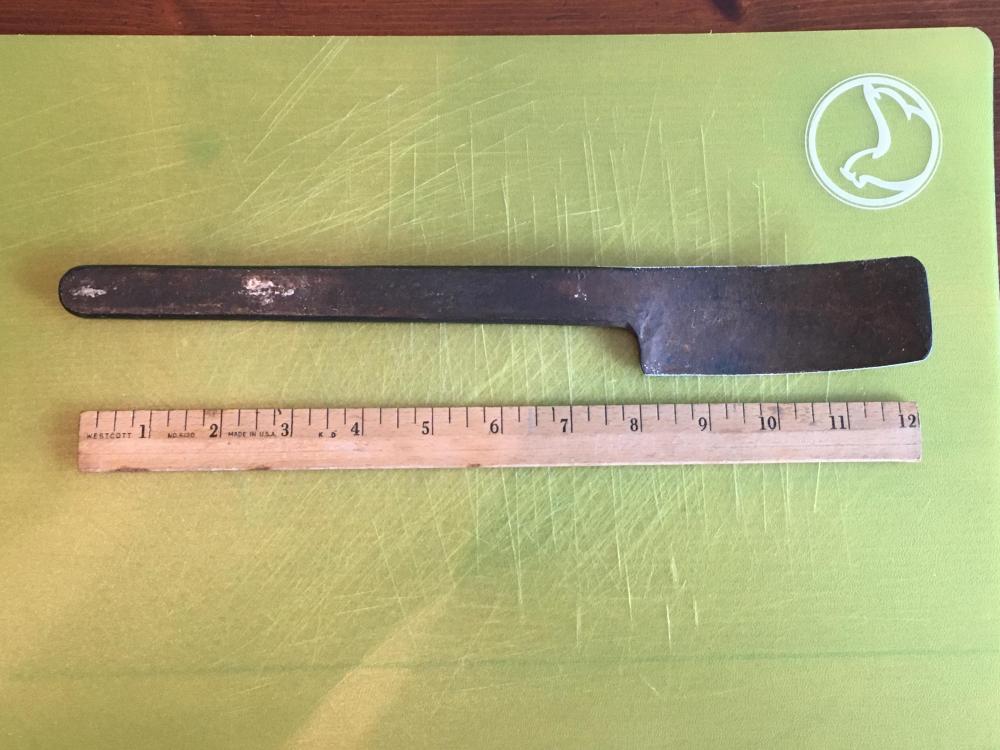

Here's another find. This was covered in rust so I soaked it in vinegar for two days hence the grayish finish. No evidence of names or makers mark but shows some indication it might have been hand forged. Both the edge and poll are hardened. The body is not. I figure it must be an adze but I've never seen one with no flare to the blade. Not much curvature either, to facilitate close work in tight radii. If I can't come up with some other use, I'm going to polish it up and sharpen it. Then, I'll haft it and use it as an adze. Hawk

-

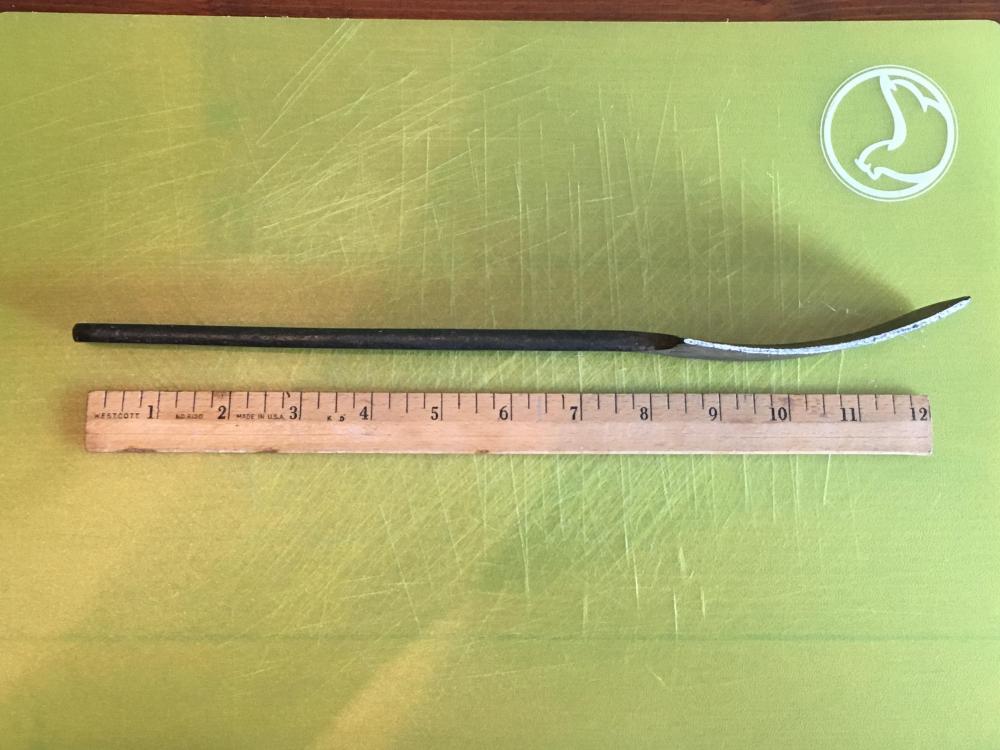

Got this in a box of goodies. Entire tool is hardened. Edges are chalked to show Demensions/taper. Curvature is approximately based on a six inch radius. Thin edge is not sharpened. Neither edge has been beat on by a hard hammer. Shows signs of being hand forged. Thought it might be a cooperage tool but can find no pictorial evidence of that. Thought it might also be for knocking the tire bead off a 12" rim. What say you experts? Hawk

-

Thanks. I have an old stainless rifle barrel that needs something.

-

Nice knife. All around nice look. About the Insta-blak, how does that finish hold up to general, non-abusive use? I want to experiment on some stainless steel. Hawk

-

Is that Thibeau handle wedge intentionally "s" shaped?

-

Just got this from the local "Restore" . Came out of their shop but the kid said they never used it. Lots cheaper than buying the materials and subjecting them to my welding. Top is 5/16 " plate and it's good and solid. Nice welding/assembly cart. Hawk

-

If we're talking about the wood pictured, and if you use it with the larger end down for stability, your anvil base will hang over at the corners. If you can go back and get a piece with a larger diameter, it might work even better. Hawk

-

Show me your anvil stands

hawk18 replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

Yup. Fat fingers for sure. Also meant the cable is too long. And, if you're bothered by my typing skills, don't look too close at my welding. Hawk -

Show me your anvil stands

hawk18 replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc

There's a 1/4" rubber casket under the anvil. I wish I had square tubing but the 2" X 1/4" angle iron was all I had. It probably would have been quieter if I could have packed the legs with sand. It's not too bad with the rubber and the magnet. Those darn bicycle lock people made that cable about 6 or 8" too short. I may have to use a piece of chain. Hawk -

Show me your anvil stands

hawk18 replied to pkrankow's topic in Stands for Anvils, Swage Blocks, etc