jtyson

Members-

Posts

11 -

Joined

-

Last visited

-

I am a safety professional by trade primarily in construction but do also work with manufacturing and fabrication shops, so the safety aspect involved with most machinery, guarding, hot work, chemicals, respiratory exposures, heat stress, fatigue, ergonomics, repetitive motion, etc are all things I’m very familiar with an understand how to combat. My job is not difficult physically, just time taxing, so I usually work on some project every single day after work for an hour or so, and every Sunday. When the big jobs I’m on stop, I will go back to 40 hours a week until the next big project fires up again. Unfortunately I am an underpaid, salaried worker, so none of the overtime I work is worth it, but unless I go traveling and take a job on the road, or switch from safety to superintendent, I don’t have a lot of options in our very limited market here. As to when I’ll build equipment/tools, when I have time. I have literally been accruing things for years for multiple pursuits, not exclusively blacksmithing. I’ve had my anvil now for about 16 months and haven’t put more than a couple pieces of hot metal on it. If I get it rolling in the next few months, cool. If it takes until some time next year, cool. If I magically end up with 2 weeks to spare and nothing else calling my name and a pile of extra cash next month, maybe then. I’m really not stressed about it. I’m not entirely brand new to this. I’m not experienced at all, but I have put hot metal down and hit it with a hammer multiple times. I have played around with propane forges. I have zero personal experience with coal other than watching other people use them. I have been taught and been around hours and hours of shop work done by my buddy who went through Robb’s courses. I’ve learned tricks and such that he learned. I’ve played around with treadle hammers. I have years of experience welding, cutting, grinding, shaping, etc. I’ve been fabricating custom parts for various projects for years. I have experience on hydraulic presses used for automotive and fabrication purposes. Many of these skills translate at least partially. I won’t claim to be ready to jump in and make masterpieces, but I am not the least bit concerned with being able to successfully pound some metal into shapes that roughly represent the ideas in my head, because they are mostly roundish, flattish or squarish. I’m not looking to forge the first iron copy of Michaelangelo here. Duly noted on everyone’s feelings about presses and power hammers. I’ll probably ignore everyone’s advice here though if we are being totally honest. To me, tools that make my life easier are invaluable, even with a learning curve. Plus, I like building things like that, so its not like I’m taking on a miserable expensive grueling task I’m going to hate just to save some time forging with power instead of by hand. I get to step back and look at a functional item I built that I can either use or sell if I don’t use. If I get to use it and it makes something easier, awesome. If it screws it up faster, so be it. I would have likely screwed it up by hand too. I work on cars a lot. For years I used a ratchet by hand. A couple years back I invested in cordless impacts and cordless power ratchets. I cannot even begin to say how much more time I could have spent driving instead of working on my mustangs, trucks or my bikes had I adopted the power tools years before while doing it all the manual way. Now granted, not a direct comparison because there’s more of a learning curve with a power hammer and I didn’t build an impact from scrap parts, but let me tell you how I know that a half inch impact isn’t the right tool to snug up intake manifold bolts on a Honda H22A. Sometimes hard lessons learned are the ones that stick. Cracked the head on that one. I do need to finish my belt sanders I’ve got parts for. For what I intend to forge, not just blades, I figure I’ll use those far more than any other tool. I don’t have any leather tools beyond a basic hole punch. I have thought about building multiple forges, just didn’t know that I’d benefit from it and space was always a concern. I guess there wouldn’t really be any reason I couldn’t build a forging “rack” per se and have a couple different larger/smaller forges stacked. Maybe I’ll draw up some concepts there and see how that looks in theory. I had tried to toy around with the idea of a segmented forge with removable blocks to shorten a long area, but ultimately scrapped that drawing because of the argument about how much hot steel you can move at once as you mentioned. I don’t really have any plans to make swords, so a 3’ forge is not likely in my near future. I have made scrolling before both cold and just with a torch, so I could continue to do that if I find that need arises and I didn’t have a big enough forge. So that filter I have, its a little smaller than initially thought. 15” diameter and only 16” tall. So it may be more suitable as a can for my “big” forge if I do multiple. My old argon tank might do well chopped into some short pieces as my “coffee can” forge as you say.

-

Dimensions on the air filter were a guess off the top of my head. I’ll try to measure it this afternoon to get a better idea. I did know that it would be on the larger side, but I wasn’t sure how much was too much. I’ve followed a few builds on other sites and was sort of mimicking one of them that I really liked the looks of. As for casting the refractory, I have zero experience with it. I had assumed that it could be mixed wet and poured relatively easily. Sounds like on the form I had the same idea that you did. Flat floor piece would be removable allowing me to peel the tube or cut the pipe sections for removal. There’s no reason I couldn’t use some flashing tin or something like that as well that would be easier to bend/fold in. I assumed standard form oil like used in concrete forming would work as a release agent. I work 6/12s and last took a vacation in 2014 so I don’t think a week class is in the cards for me. I have to squeeze in time to read and respond on here late at night or while I’m at work at my desk when there is a little down time. I know for a fact my father wants to make knives and as you said, stock removal is a lot of that, so thats why I intend to finish the 2x72 grinders I’ve got parts for. I also want to make knives and similar but I also have ideas for other things that will require large stock. My thinking is that if it is painful and slow, its less likely either he or I will enjoy it as much as if there were power tools involved that made the process easier on the body. So while it may be the norm to wait a few years before delving into presses or power hammers to see if the hobby sticks, I’d rather give it a run from early on. Especially the press as I could easily use that for metal forming and automotive things that I already do anyway. The tire hammer or any power hammer is a niche item that I think I should be able to recoup my costs on, bubble burst or not. On that note, I’ve seen posts for years on multiple forums about the “damage” FIF has done to the hobby and market and everyone always says its going to get cancelled or go away and several of those posts are over 5 years old and its still on. So while I’m not making my decision based on resale, I’m not avoiding it for fear or things crashing. Worst case scenario I’ve got a bunch of tools should I choose not to keep up with it. The only thing I’ve spent real money on was the anvil at about $4.50/lb. When I was first introduced to blacksmithing I think my friend paid $2/lb for the anvil he got and Robb had to repair it so I don’t feel like I spent astronomical money on that one either. Other than that I am only out the money for forge supplies. So collectively less than $1300 in it right now. I’ve got almost that much money into my welding table alone. More into each of my welders. So really, not a huge expense thus far and even if I build a press and a power hammer, I don’t figure I’ll be any more than a few thousand in, and likely much less. I’m pretty thrifty. The anvil, from what I was told on another site, is a Firminy Forge French anvil. It doesn’t have any markings that identify it, but judging by what I’ve searched online after getting that info that seems correct. It has a little chipping on one edge but otherwise is in very good shape. Rebound is nearly perfect. It came from a lady in Arkansas who had several anvils for sale, a few like this and some London patterns, some much larger and significantly more expensive. I wanted the 375lb but didn’t want to fork out $1700 for my first anvil.

-

I haven’t had the time to do much of anything this week for myself as I’ve been on the road and in the field for work. First time I have looked at this thread since last weekend. Admittedly I haven’t ventured out beyond this thread either. I’m not sure where everyone congregates on here but maybe if I have some down time at the desk today I’ll spend it cruising around and seeing what day to day posting looks like. I’ve seen all sorts of different cylindrical items used for forges. I’ve got a handful of things at the house I can use but haven’t decided on what yet. I’ve got a few propane tanks. Have an old argon cylinder. Have a couple kegs. The one that I’ve been eyeing the most is this air filter purifier thing I snagged at an auction to resell that I haven’t been able to. I don’t know dimensions off the top of my head, but I’d guess its about 16-18” in diameter and about 2’ tall. My thought was 2-3 layers of the 1” ceramic blanket, then use either sonotube or some leftover scrap utility pipe I can snag from work in the 8-12” range and shape that into a round area with one side flat that would be the floor and then basically cast the smoothset around the tube. Fab up doors and pour them solid. BUT….I need to do more research about volume/area of the inside of the forge. I don’t want to limit myself with something too small, but I don’t want to build something so oversized that it won’t heat proper or will waste a ton of fuel getting up to temp.

-

I don’t use a computer very often, most of my access will be from my iPad or iPhone. Playing with the photos, there is no way to double click it but it pops up and gives a resize option, but not by DPI or pixel dimensions just small, medium, large and original with associated size. This is a medium photo of my anvil. If you guys see it on your end and it’s too small, the next photo I upload I’ll try the large size. The SDS sheets I uploaded earlier were original size because I couldn’t figure out the double click bit then and didn’t notice the resize option. In 1990 I was 3, so safe to say you’ve got me there. I’m a big fan of all the tech advances that make communication online simpler, but I do realize they take away from the human part of communicating. The @ function isn’t really “right” as you say anyway. On here where things are likely pretty low traffic when more personal connection, it would probably be a waste anyway. But on Instagram or Twitter, when you’re posting amongst a feed of thousands or more, without that tagging function for people or hash tagging for topics, it would be total chaos. So I guess everything has its place. I don’t typically use google chrome but I’ll try to remember to give that a go for searching. Because when I just googled tpaaat without the site direction code, I got absolutely nothing that made any sense. I do get the drift of the method. I may have to start trying that. I guess I sort of do that now, but not necessarily quite as forward in asking everyone I come across. I leverage my work connections more than anything. I did notice the lack of monetization on the site other than the giant floating banner at the bottom of my screen and donator buttons. I can appreciate that. Bringing value without the commercial aspect that typically accompanies forums. I typically end up a contributor or donator on any forum I join that I spend any amount of time on as that is usually how you get rid of the ads. I have no issue avoiding controversial topics. When I come to a forum, I’m generally there for discussion about the topics relating to that forum, not just as a chat room. I’ll have to actively try to watch my language. Generally speaking online I don’t speak poorly, but in person, well that is a different story. Here is a smaller photo size for reference 500x375 same kB Mod 30

-

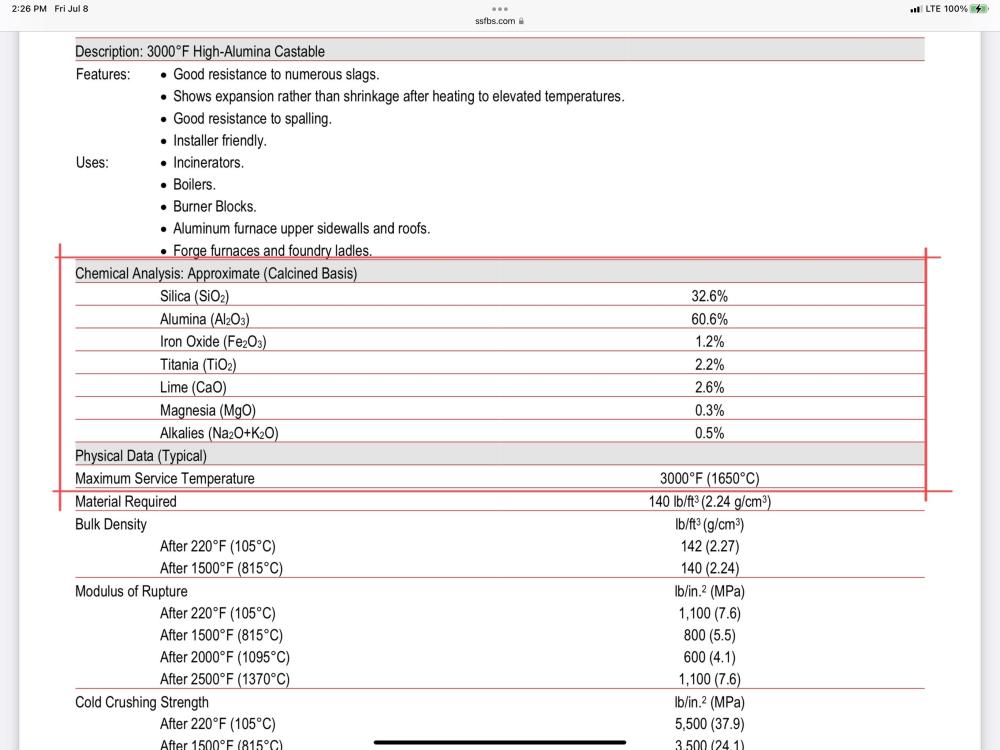

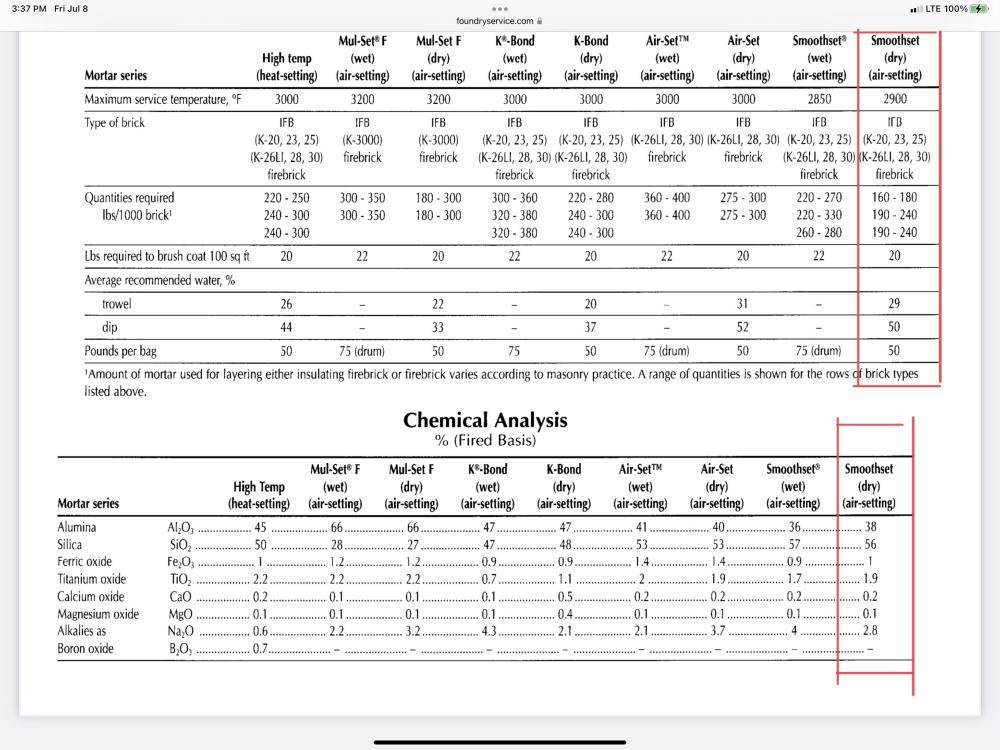

In my years on various forums I’ve always found that the most direct and clear approach nets the best results. I never assume the “audience” is interested in deciphering which part of my rambling is intended to be a response to them or directed at them without directly @ them or quoting. If this group here is able to carry on a discussion without that, this place will definitely be the exception to the rule in my experience. Sorry for the lack of clarity on the SDS sheets. The top one is for Mizzou Castable Plus and the bottom is a generic sheet for all the thermal ceramics mortar family and I put red boxes around the smoothset dry which is what I have. Basically the same numbers between both with the exception of the silica and alumina being opposites. The Smoothset at 56% silica and 38% Alumina while the Mizzou is only 32.6% silica and much higher at 60.6% alumina. I am not a chemist and I don’t really know what all that means. If I’m being totally honest, when comparing notes and deciding to buy the Smoothset, I had flipped the numbers and thought that they were nearly the same and just a few points off each, rather than being flipped. I know that alumina is aluminum oxide and silica is basically sand but their functions in the end product I don’t know. I’ve got a very minor grasp on the what, and basically zero concept of the how. If you understand more and are inclined to give a layman’s description I’d be interested in learning, but don’t expect it by any means. You seem far more knowledgeable than I am so if you think it is suitable and not something I should toss aside and just bite the bullet and order Mizzou or something else, then I’ll run with it. As for adding the “bubbles” as you say, is that really beneficial when just using the mortar as a rigid layer on top of the ceramic blankets anyway? Or is that more appropriate when casting a mortar-only forge? I had seen Plistix and Metrikote mentioned elsewhere as well. I was never able to find a clear answer as to what was better between those and the ITC100 and I believe I chose the ITC because it was the most expensive - and not by a small margin, and thus I figured must be the best. So regarding the bandwidth thing, do you guys not share a lot of photos? I’m very much a picture person myself. Or are hosted photos from another platform better?

-

Yeah I’ll stick around, just see that a lack of quotes leaves a potential for confusion and the people I’m attempting to talk to not being notified, but hey their house their rules I guess. So what is TPAAAT? All the bolts I have are black iron. It’s leftovers from a brand new build. They are from the Amazon that they are putting up in Los Lunas. I got to haul off a bunch of leftover structural steel that was headed to the dumpster. Included in that was a ton of hardware. I kept all the bent plate, angle, box tube, plate, dowels, etc. I was gonna trash the hardware and a couple hundred pieces of 4x4x.5x12” long angle with pre drilled holes for scrap price. The rods I have are about 14” long and 3/4” not 1” as I thought previously. Please let me know if you can think of anything that I’m potentially going to throw out that may be more useful or valuable elsewhere. I’m all about being thrifty.

-

Well first thread and already got a warning. Guess I probably won’t last long here. Sorry to have inconvenienced you guys. I’ll stick to reading and avoid posting unless really necessary. Thanks for the welcome and answers to a few questions already.

-

It never occurred to me to check the scrap yard for tools to fix up. That could potentially be a new distraction waiting to happen. I don’t have the room to store the stock or anything. But I keep it all anyway. I need a 100x100 shop. My 25x30 garage is overflowing, have piles of stuff out under my carport, and a bunch of steel and other materials in my back yard. It is a little bit Sanford and Son over here. But yeah, if you think that those rounds would be valuable stock to hang onto I will. How about a grip of 3/4” bolts and hardware? All leftovers from a large box store build I’m on. I’ll probably only get a couple hundred bucks for it at the scrap yard but if it were valuable forging stuff, I’ll make a pile. Well I can’t totally blame the internet here. The “comparable to mizzou” was something I discerned by reading the SDS. Maybe I wasn’t looking at all the right info though. I don’t know if I have permissions to do so, but I’ll try to attach the two SDS’s to show you what I was looking at for comparison and why I figured it may not be just as good, but close enough to be a negligible difference for the application. As for the ITC 100 I paid way too much for it, so I’ll use it but I did expect to be recoating pretty regularly. Everywhere I read said that it does require that. I am curious though, could you point me in the direction of whatever product on the market now is better? That way I can look that way for the next one. Maybe its because I’m young and part of the do less get more generation, but I just feel like at this point, propane is probably the better way for me to go. That way I can spend less time worrying about the fire and more time worrying about what’s in it. Maybe thats misguided thinking though. Also, as a safety professional, I’m leery about breathing the coal dust constantly because I know myself well enough to know that I won’t wear a respirator all the time and won‘ t shave my beard to wear one properly. I can move air and dissipate carbon monoxide easily from a propane set up. I agree about availability being important in general, but obviously haven’t experienced that in relation to blacksmithing. Something about the old time nature of the craft just doesn’t bring about any sense of urgency for tool acquisition in my mind. But I guess if I were mid swing on a commission piece and needed something special to get it done, that would be a different story. Either way, I should get back to checking those places for good deals.

-

Eh nothing to be jealous of. If you’re a machinist you’ve got the skills that I should have. Anyone can buy tools. Can’t just buy skills. Lol good catch - not hydraulic. Pneumatic. Can’t edit that out now though, gotta leave that stupid to shame myself to any readers to come lol. I was loosely diagnosed and treated for ADD as a kid but always thought it was BS. However as an adult that struggles to focus on or finish anything, I realize it was probably correct. I too have dozens, if not 100+ projects half finished. Currently have 3 project motorcycles that have been sitting untouched for 2-3 years. I always blame time and money, but I realize that if I didn’t pick up 800 new projects in the last year then I would have more time and money to finish those projects that have been sitting. To make it even worse, my side hustle outside of my regular 60 hour work week is buying/fixing/selling broken things. Everything from tools to electronics to furniture to cars. And I always give those projects precedence because I have money tied up in them that I need to get back. Hobbies always go to the back burner. Sorry to hear about your PTSD from the service. I can’t begin to imagine what that is like. Hope you’ve got a decent handle on it, even if being an introvert isn’t your first choice its better than some alternatives. I’ve got an absurd amount of short round stock that I was going to take to the scrap yard that I didn’t even consider keeping for something like tongs because its all mild structural steel. I can’t remember if it is 1” or 1.25” but they’re about 12” long. Would that be worthwhile hanging onto? I’ve probably got 2-300 pieces like that. I’ll have to consider Ken’s for sure though. Time and worth are interesting. I have very little free time, but what that is worth I guess depends on who you ask. I will say that in general, if I can buy something that is already built for close to the price that I can make one, I will. That means that I have to be patient. I often buy my tools at estate sales, in bulk lots, online, etc so that I can get them at a steep discount. I will look into the local groups. I know that I should open up a bit and use the resources available to me beyond the internet community. I’m curious why you suggest a coke forge being in the city? Just the noise? Admittedly, I don’t like the idea of the maintenance required in operating a charcoal forge. I know my friend that introduced me to things switched from propane to charcoal but he lives out of the city and has the space to store a truck load of material. He was wanting to be able to get more heat than he could with his little 3 Venturi burner propane unit. But I don’t know if he ever considered forced air and different burners to get better heat. I personally figured the cleanliness of propane and availability just down the road from me was worth the trade off in cost/noise. I have used a treadle hammer briefly a couple times and the action felt clunky to me. But so did all of it, so that probably wasn’t a good measure. I do know that a power hammer would be louder and less neighbor friendly, but the way I justify it in my head is that if I use a power hammer, only during the proper hours, then the time it would save me over hand hammering everything taking many times longer. I have also considered that my father has shown interest in this as well, and physically, he is in kind of rough shape so power tools make things possible for him that otherwise would be completely off the table. With that said, I think that a hydraulic press will be my focus before a power hammer as far as the big tools go. For ease of operation (tool speed) and noise. I live in the NW part of the city. I used to check the antique shops for smithing stuff, but have found that once it became a more popular craft that was televised prices on everything even in there skyrocketed. So I haven’t looked in a couple years. I ought to still though. I’d say I fall into the category of beginner very firmly. I’ve made a couple ugly pieces of hot metal over the years, but nothing that would make me say I have any experience. I have been passively researching the topic for several years, and in the last year or two started compiling articles and reading forums and such to try and point myself in the right direction. Unfortunately, as it goes with the internet, there is no filter that stops people from posting bad advice. So it is possible that what I’ve read and watched wasn’t the best idea, but was posted and copied by a lot of people that didn’t know any better. Lots of people seem interested in regurgitating information they’ve seen, but never actually put into use, so I try to do my best to filter out what seems to come from knowledgeable people with experience versus knowledge from people that know how to copy and paste. That still requires my judgement on an unknown subject though so plenty of room for error on all sides. Considering I already purchased all the things that I did for the forge, I’ll probably roll on with making it since I can’t return any of it anyway and I’m already out a few hundred bucks. Assuming there isn’t any safety concerns with the materials, I’ll try and run it until it fails and then do it again. I hate to do it that way, but being I can’t get money back on what I have, its going to be a loss either way. I do feel like I’ve got more than enough to get started, other than obviously need the forge. I don’t have a rosebud for my torch, which I often kick myself for. I really need to buy some new stuff. I haven’t had any contact with Robb or his sons in years. I was only around them a few times through my friend who took a class there with them and then ended up being friendly with Robb. He drug me along when he was going to their places. I couldn’t say what they are doing to be honest. Last I saw them they had the big school out East of the city about half an hour. I drive by there sometimes, but never stop in. I don’t know them well enough to do that. My direction specifically is kind of all over the place. Knives for sure. Small artsy stuff - decor type things. Accent pieces for larger items - so like maybe some ornate twists to go on a security door instead of the same old generic basket twist. Or maybe some fancy brackets for shelves. Or some feet for a custom table. Who knows. In fabrication, I mostly build gates, but I don’t do that much anymore. I also work on cars and bikes, so being able to forge small custom pieces for mounts or accents. Also why I’d like to be able to melt. I’d like to be able to play with making some small thin custom panels with a planishing hammer for gauge covers, trim pieces, etc out of bronze/copper/brass. Body jewelry - I’ve got some ideas in my head about mixing wood/metal for some neat pieces. I have a family member that is sort of highly modified and always thought that the price she paid for tunnels/gauges for some really ugly stuff was absurd. That’s some of the things. I could probably sit and come up with a number of other odds and ends I’d like to make custom instead of buying what’s commercially available. I’ll definitely look into the NMABA stuff and if I can clear some time try and check out some in person stuff too. I don’t know how many tongs I’ll need considering my ideas are all over the place. I haven’t been to Amador but I appreciate that heads up. I happen to have a connection to the Acme recycling group through my work and they’ve told me that I could buy scrap off of them if I ever felt like walking any of the yards. I intended to do that when it came time to find big iron for hammer/press frames, but I think I may have covered myself with what I was able to bring home from the current project I’m on. It didn’t occur to me though to go and look for tool steel or tools themselves.

-

Profile edited and some information added. As for the forge stuff, the stuff I bought was picked after doing quite a lot of reading on building and such so I’m surprised to hear you say that. I did buy some cheaper/generic versions of a couple things due to availability and price, but thought I’d be headed in the right direction. I bought amazon ceramic fiber fire blanket insulation which is comparable to kaowool. Smoothset refractory mortar which is comparable to Mizzou but what they carry at my local clay store, and the ITC100HT I see touted everywhere as an excellent refractory ceramic finish to keep heat in the forge. I’ll spend some time reading, but man, that is disappointing if I’m wrong about all I’ve already purchased. Yeah the reading/videos I’ve watched have pretty much sold me on casting a ribbon burner for the forge. Not positive for the melter as I haven’t done as much research there. I’ve seen Ken’s mentioned. Is it worth spending the money on blanks versus just making my own? I mean if I still have to shape them anyway, is it worth the time saved? I see so many shops with 40 different sets of tongs and I just can’t imagine it would be worth buying blanks for all those when you could make them, seemingly relatively easily compared to many other things. I’m in Albuquerque just up the road from you. Actually I know nothing about the meetings. If I’m being honest, I don’t tend to be a get together type of person. I know conventional wisdom says to learn from those near you and join a club, but its not really my style. I’m more of the struggle and learn it on my own time type. I like written info and short videos because I can squeeze them in around work hours. But who knows, maybe I’ll look into it. August though, not likely.

-

I’m Jeremiah. New on here to posting, but actually joined several years ago. I’ve been exposed to blacksmithing and metal working for a long time. I’m in New Mexico and have a friend who introduced me to it a long time ago after taking classes with Robb Gunter and his sons. I met them, got to spend a little time in their school and at Robb’s forge and see what its like when a true master puts hammer to iron. I didn’t really appreciate it then to be honest as I had other interests taking up my time, but in the last couple years, I’ve been trying to set myself up to be able to do some more hot metal moving. As my title states though, I tend to get distracted, sometimes for a few minutes, sometimes for a few months with other things and life and such. Might be a bit wordy, but I’m going to lay out all the irons I’ve got in the fire and if anyone should choose to give me some ideas or criticism, I’m sure I could use it. I’m not brand new to metal. I have been welding and fabricating for over a decade, a portion of that professionally. I still have a good chunk of equipment from my business, so I’m way further along on getting set up and getting ready to get going than a lot of people who are already producing awesome stuff with minimalist forge set ups. I know I don’t need the biggest, shiniest and nicest, but I do tend to spend time and money hunting down good tools, building things that make the process more enjoyable, etc. I try to spend once as often as possible rather than start small and upgrade if it is something I think that I will be limited with. I intend to make decorative things, knives and other tools, ornamental stuff for things like gates and doors and such, body jewelry and who knows what else. Tools I’ve got - Not an exhaustive list, just ones I can think of that are related to this trade. MIG Welder - Miller 211 TIG welder - Lincoln Square Wave 200 Oxy/Acetylene rig with Victor torch. This admittedly probably needs upgraded. I only use this as a gas axe, rarely ever weld or preheat with it and its vintage so probably needs upgraded. Southbend 9” lathe Jet Benchtop Drill Press - I need to find a floor model as this often limits me in my projects. Kalamazoo horizontal bandsaw Racine power hacksaw - I’m rebuilding this one and not sure if I’ll keep or sell. I’ve been told they cut cold stock very cleanly, much better than horizontal gravity feed bandsaws like mine. Multiple portable bandsaws. Working on turning one of my corded ones into an upright table top unit. Several corded and cordless angle grinders Multiple die grinders cordless and hydraulic. Tormek 2000 grinder - I use this to sharpen tooling, chisels, etc but also use it on knives as well. Dewalt Metal Chop Saw - I hate this thing and rarely use it. But it seems like a staple in a number of forge shops I see. 4x8 rolling adjustable height welding table - Poorly described. This is my flat surface that is constantly full of so much stuff I can’t use it. Wood shop tools - because wood and metal have to play together sometimes. I’ve got a low grade hobbyist shop worth of these too - cabinet saw, upright bandsaw, lathe, jointer, chop saws, radial arm, scroll saw, 10 million clamps, routers, etc. This is relevant because I’d like to make metal things that have wood parts and wood things that have metal parts. Firminy Pig 218lb anvil - I’d like to build a stand instead of the cottonwood stump I have it on. Unknown brand leg vice - Kind of an ugly piece that someone chopped up and welded some stuff on, but it works. I need to mount it somewhere there. Currently bolted to a stump which is basically worthless. 6” bench grinder Tools I need/want Forge - I am going to make one. Trying to decide on design to do it right the first time and hopefully not need to switch it up too soon. I have 3000 degree mortar, 1” roll of knock off insulation. ITC100HT coating. My intent is to build a forced air ribbon burner. I’ll need to getting all pipes, fittings and maybe a blower for that. I’ve got a blower, but it may be too much to use. 2x72 grinder(s) - I’ve got motors and some of the steel to build two of these. Need to buy VFD controllers and wheels. Was thinking about turning my own wheels, but don’t know that will be worthwhile on cost. These will be 2hp and I’m not sure if I’m going to build both and sell one to recoup some money, or if I’m going to keep both and put together a Frankenstein machine for grinding double hollow bevels for knives. Melting Furnace - I figure on this basically being an upright version of my forge maybe with a forced air Venturi burner though. Not sure on ribbon for a melter. May also consider oil burning. I intend to do some work with copper, bronze, aluminum, etc and want to be able to cast things and have ingots to work. Hydraulic Press - I know this isn’t a must have, but it is for me. My father wants to use this stuff too and he has had two shoulder replacements, so too much hammer time isn’t likely in his future. Also, I’m in the city and probably need to limit noise as much as feasible. All I have toward this is some of the structural steel. I’ve got 6x6x3/8 box tube, bent plate, some small I beams, 4x4x.5 angle, 5x3x.5 C channel, etc. I’ve got a good amount of scrap structural leftovers from my regular job that I’ve been able to take home. Power hammer - Again, I know not a must have, but I’d like to put one together sooner rather than later. All I’ve got toward this is the steel too. Well I may have a motor. My intent is to build a tire hammer or an air over hydraulic. I haven’t spent too much time deciding there. Hammers - All I have are some old hand sledges and harbor freight stuff. I’ll probably stay cheap for a bit until I find what I need, or make what I need. Tongs - I have zero tongs. I’ll need to either buy a couple sets or make a couple sets to get rolling. Just figure buying will be more likely considering I probably wont be good enough to make anything for a while. Heat Treat Oven - Considering I’d like to do some blades, I figure I’ll probably keep an eye out for one of these. My life is chaos, I’ve got 100 projects always going at once, but I’m trying to get this set up relatively soon so that I can make cool stuff and my dad can give it a try.