-

Posts

5,754 -

Joined

-

Last visited

About jlpservicesinc

Contact Methods

-

Website URL

https://goo.gl/photos/jNR8MRdz5TSU3Nm47

Profile Information

-

Gender

Not Telling

-

Location

Rutland, MA

-

Interests

anvil making, utilitarian tools, hardware, tooling, knife and sword making. Martial arts tools especially Ninjutsu.. Industrial forged items..

Nin video link.. : https://youtu.be/yfQaqeF9MaA

Recent Profile Visitors

-

JLP Blacksmith Teaching Center.

jlpservicesinc replied to jlpservicesinc's topic in Building, Designing a Shop

Well it's been some time since an update.. Been busying with other things in an attempt to get caught up some with other things on the list. Hikerjohnson came down last weekend for some course instruction on an upcoming class he is assisting with. While here he mentioned that I might really want to look into pallet racks and to do it sooner than later.. I asked him how he was stack the shelves I have and he laughed and said he would not recommend it.. I've picked up several new to me pieces of equipment of note was a "Cincinnati Monoset Tool Grinder". This is a very good tool grinder. It started when I wanted to use the pantograph thinking I had bits and I did not have the right sized ones.. So I went online to look for a tool sharpener for the pantographs.. Deckel SO were in the 2-4K range.. I then searched FB market place and this grinder I had seen at 3k and dismissed it. When I looked again it was half that. I spent about 40hrs cleaning it and the work holder drive motor. Ordered some of the missing parts.. Today was the first time running the machine and I have a lot to learn. Worked on sharpening this drill bit that had nearly 3/8" off of one side. I then tried to split point it. Lots to learn. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Frosty, that is the air shear. They forge 4 bits at a time.. they cut them into 2, 2bit sections before the bar goes back in the electric oven. I'm teaching a "forge welding" class up at Haystack Mountain Craft Center in a month and member Hikerjohnson here, is going to be my assistant.. So Saturday he came down to go over course outline and to show him how I work these projects out.. I made the item, then HikerJ's turn.. These of the sample pieces I forged. We made really good time.. Hiker (AKA Eric) is a smith on his own right and runs a shop up in Maine -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

You bet.. Not really sure which photo you are referring too.. There is a pneumatic shear that is in one photo. On the right side of the hammers, The shrouded foot pedal is the electric/pneumatic activator on the hammers.. No foot treadle.. (Foot treadles are not osha approved) Was very interesting.. I was told that most of the hammers are worn out.. This was before I saw the operation.. Closed die hammers need a very tight running tolerance.. Open die hammers not so much.. I mentioned this to the engineer.. I'd be happy to have one of the hammers show up at the school.. These are drop hammers power up only.. The really big hammer is a hydraulic/pneumatic hammer and has power up and power down. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Few days back I went to what is left of the Simond's forge shop. Simonds was a huge company.. Not so much now. Like many American born and raised company's who found a footing and lost their way. -

Hey, in todays market it might be a good move to pass it along. Your journey has been pretty amazing and have done such a great job at setting up your shop.. I still have my first real anvil HB 175lb and have had it nearly 40 yrs..

-

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Rojo pedro that looks great.. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks for the nice compliments on the Compass.. I needed a hand crank for my Wisconsin engine. At the filming session the owner was kind enough to turn a wooden handle to go over the steel sleeve.. The sleeve was then glued into the wood. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Great idea there Mr Frosty with the pig tail.. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

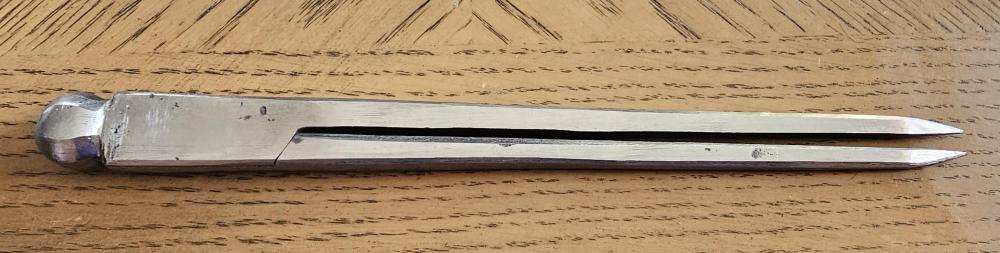

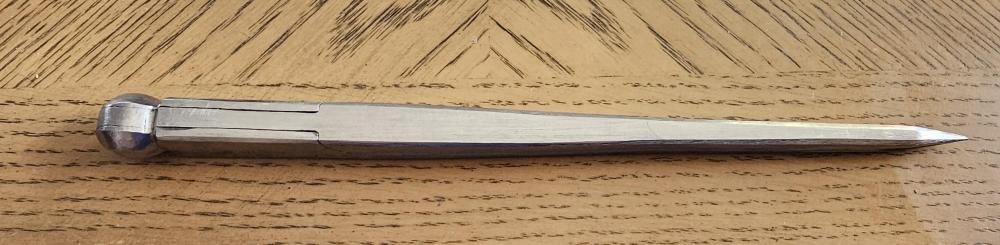

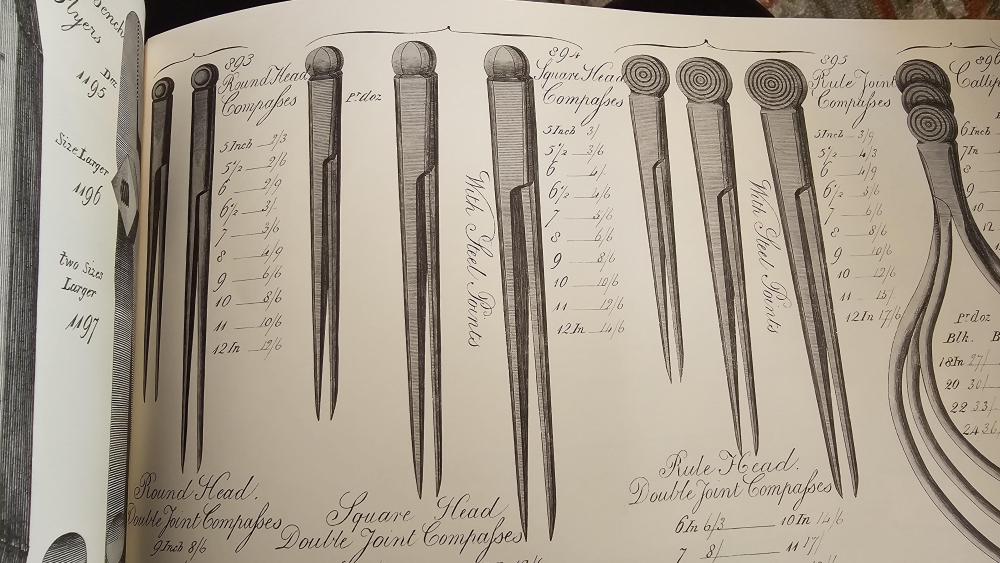

John, Looking good.. I wasn't sure where you were going with those pads with the hooks on them but it all came to light. Looks great.. Your getting good at the woopytydoos. I spent some time again at the "Moses Wilder Blacksmithing shop" in Bolton MA filming for the EAIA on compasses out of the Patterns book. My first one is complete.. I made a few pieces trying to figure out how they were commercially made but once that was done it went pretty well.. Wrought iron with rasp steel tips. I should throw it in the acid while it's still so clean.. Never thought about that till now. Not my cleanest work. Decent for number1. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Gewoon Ik, Hey, your making some progress.. Very nice.. 6mmX 20mm starting stock? I forged out most the parts for an Air cooled Wisconsin hand crank start lever. Was only going to forge the socket (1" ID) but then was having too much fun.. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

David is this unit going to be use to Baton thru bone also? Years ago when I was "into" knives I had looked into cleavers thinking there was only 1 type.. 14/15yrs old. I soon learned there were many types.. I had gone to an old meat processing place and seeing their cleavers and the edges was educational. They would saw thru larger bones.. The cleavers were used for joint separation and any soft to hard tissue junction. (knees, hocks, shoulders, ribs). I'll be super interested to hear how the 8670 holds up against the cutting of the bones.. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

gewoon ik, very nice pineapple handle. -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

David, love the shape and handle. Is this a thick cleaver for processing large pieces or a thin blade? -

What did you do in the shop today?

jlpservicesinc replied to Mark Ling's topic in Blacksmithing, General Discussion

Any course is a good course.. The ABANA course is based on the CBA course layout but reworked slightly. It's a great course and covers nearly all the bases for an Artist blacksmith. The course outline is on the ABANA website which has been upgraded fantastically over the last few years. https://abana.org/education/ There are a lot of talented and skilled smith involved with ABANA... The reason why I said it that way is because of how approachable these longer term/skilled smiths are. The next ABANA meet is in JUne. -

jlpservicesinc started following Söding und Halbach S&H Anvils

-

Sound or reverb depends a lot on how the anvil is resting.. If the reverb when struck is dampened it won't ring much. It's the reason people put magnets and such on anvils.