-

Posts

243 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Litchfield County, Connecticut and NYC, New York

Recent Profile Visitors

3,368 profile views

-

Hello everyone. I've been trying to get some ferric chloride set up for etching some damascus I've been working one. I bought some muriatic acid from home depot and started the process of turning it to ferric chloride but it seems to be leaking through the PVC pipe I have to hold it. I've looked around and I didn't see anyone else come up with a similar issue. I'm storing it in a 4" pvc cutoff with an end cap on the bottom. I thought maybe the acid was eating through the glue but the cap is still stuck on there well and I don't see any holes in the pvc. What do you all use to store hold your acid when etching?

-

Looking for a book - Damascus/Pattern

MrDarkNebulah replied to Shamus Blargostadt's topic in Knife Making

I second TP. The Pattern Welded Blade is available through ILL in the NY Library systems, so its a good bet your library will be able to get it. It definitely is worth the read and helped me alot on m first (and still ongoing) attempt at damascus. Somewhat related, I know we have multiple authors in the iforgeiron population and I was wondering if there's any custom in recommending/not recommending more questionable sources of obtaining the books? -

That was the exact meet he told me yea. It also inspired me to try damascus, but I've made alot less progress on it than that.

-

I went to a blacksmith meet a month ago and they told me an easy way to get ferric chloride is to buy some muriatic acid from home depot or lowes and then to let some iron to dissolve in there for a few days and then add some hydrogen peroxide and viola, ferric chloride. That is what Matt Parkinson at Dragons breath forge told me he does at least.

-

It seems that the whole issue boils down to "Is it a risk you're willing to take?" or more importantly, "Is it a risk you're willing to let someone else take due to your work?" It's a beautiful knife, and definitely above my skill level, but with Slag's very noticeable points, it might not be the best in a kitchen.

-

Thanks Steve, that seems much more accurate. It also seems like a much more complex steel and heat treat than I am ready for, unfortunately.

-

So the steel supplier accidentally sent me ABL Stainless instead of 15n20. I looked online for a bit and in the heat treat app and I couldn't find anything in regards to it. I might have misheard him, but replaying the message it sounds an awful lot like ABL Stainless. Can anyone help shed some light on this?

-

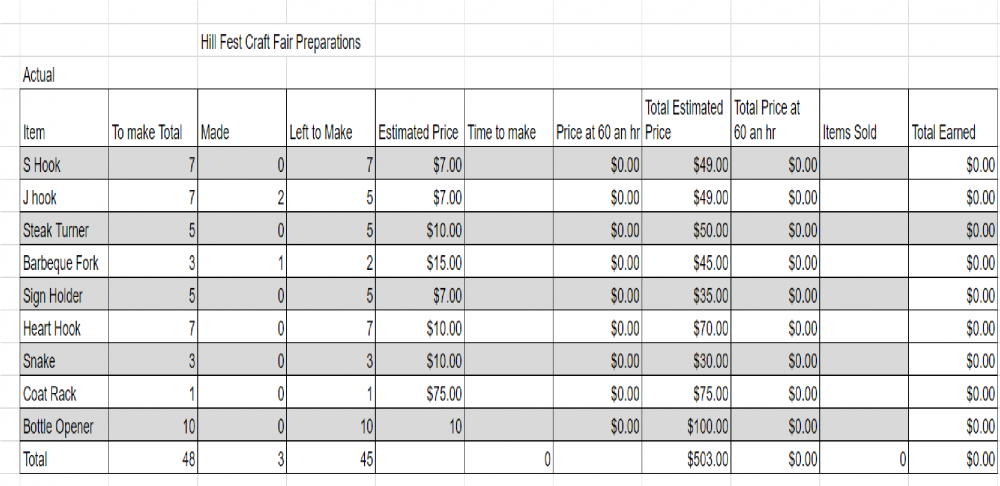

Craft Fair Preparations

MrDarkNebulah replied to MrDarkNebulah's topic in The Business Side of Blacksmithing

Yes, I agree with a lot of what you guys are saying. The estimated price was what I was thinking of initially, but while typing I thought it was too low so I added the 60 an hr column. That column is set up so that once I record how long it takes me to make them I can then have an accurate pricing. Y'all are right I don't know much about any of this, it was more of a spur of a moment decision in which my sister had already paid the booth fee and offered me a spot. I'm looking at it as more of a learning opportunity than anything else. Latticino, that is a good point about the package items. I was planning on trying to set up some sign holders/frames to sell as packages. Thanks for all the advice guys. -

Craft Fair Preparations

MrDarkNebulah replied to MrDarkNebulah's topic in The Business Side of Blacksmithing

You'd be amazed at what you can accomplish at 3 am when you're procrastinating studying for finals. -

So my sister is has a booth at a craft fair to sell some things that she has been making (custom signs and other home decor) and asked me if I could come along and help her sell things. I thought that it would be a good opportunity to try and sell some forged trinkets and stuff, since she already has a booth and agreed to the proposition. However, I have no experience when it comes to this kind of stuff. After some reading from previous posts, I came up with a list of things I'd like to try to have prepared for the fair. What do you guys think? I don't know how realistic any of my pricing is, like I said this is the first time I've ever tried to sell anything I've made

-

Sorry for the quote thing, I should've known better. Thats a very helpful graphic JHCC. When calculating volume like that is it worth it to worry about scale or is it so minimal that it doesnt matter?

-

Thats the plan, but things often dont go according to plan. I've never tried tig welding without a filler metal, is it much different from normal tig welding? I'm leaning towards using wire mainly because I don't trust my normal welding abilities.

-

So welding one end got it. I have very little experience in arc welding. Would tig or mig work just as well? Also, is there any preheat/postheat I would need to worry about for 15n20 and 1095 in this case or does it not matter since I'll just be putting it into the forge?

-

I've been starting the long process of trying to make some Damascus. I have so 1095 and 15n20 that I have ground to 80 grit with the grind lines running widthwise. They are currently sitting in Ziploc bags covered in some wd40 to prevent rusting. I have about a week and a half before I'm out of college for a bit and can get back to the forge. So, I've been trying to make sure I have the process down (at least what I should do theoretically) and am doing the correct prep work. My set up is a coal forge, some mule team borax for flux, and some hand hammer and maybe a striker if I can convince my twin brother to strike for me. I've been reading The Pattern Welded Blade to help, and it has alot of good information. (You guys actually do know what you're talking about when you say to get started by reading the books. Who'd've though?) Like I said I have the steel cut into 1.25" x 6" x 1/8" sections and ground to 80 grit. To my understanding, the next step is to weld/wire up the billet. Now in PWB (Pattern Welded Blade) the author recommends to use wire to wrap the billet together, but nowadays I see a lot more people just welding them together. I know Frosty (i think its frosty correct me if I'm wrong) recommends welding the near side of the billet and wrapping the far side. I was wondering what you all thought of this issue. PWB also recommends soaking the billet in a mix of boric acid and borax before starting to weld. Has anyone tried that? Does it work? I've forge welded mild quite a bit before, but I haven't forge welded much high carbon to high carbon before. In general, do I have the process correct? what tips do you have for me moving forward. Also, whats the best way to take the oil off of the steel before welding? I've seen people use acetone or a special degreaser, but I've never used any of that before.

-

Could you explain(not necessarily explain but show what it is) the math behind calculating the length needed for the taper?