-

Posts

269 -

Joined

-

Last visited

-

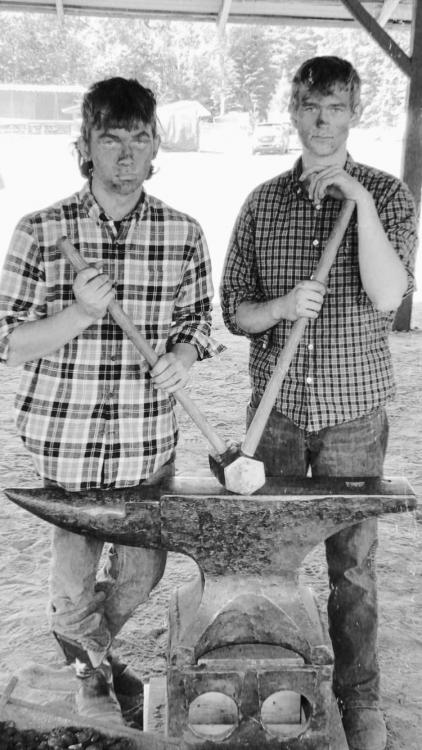

howdy from WA, very cool to find you on here. i watched your video titled making 100 round hamers as soon as it aired give or take, (this was before i had discovered you channel) THAT POWERE HAMMER THO! and i loved the segment where you gave us a little insight into your journy as a young black smith, the trip to the UK, and so on.

ill admit im not like a alec steel super fan, i only recently discovered who he was. i good do with 25 segment videos. BUT i like his and sam and was happy to see them expanding and laying a foundation for an actual what should be succussfull business, i think he's put the work in and id rather see people spending their money on something made from someone whos done the work. but when i saw the vid of the unboxing i was like what....domestic outsourcing? whats keeping then from maybe not spending 5 months on a fuckings sword breaker with a diomand encrusted edge and just fire up the power hammer. then i thought more about it speculated that maybe alot of him being where he is now was likely alot to do with the work he put into youtube and his fan support. so if thats true that would make each upload a valuable part of business.. but 16 parts g'dang... joking. then i watched your video and it all makes sense and now i want a hammer! not to mentionn the hammer eye tongs! one day

.thumb.jpg.9192bd4c7ad116cf8f6005af51f7654b.jpg)