-

Posts

274 -

Joined

-

Last visited

-

Lazy Susan?? thanks for the encouragement I have to go to a mechanic or a scrap dealer to recover a rim or an old pulley or an old gear to make the base the tubes for the upright truss I fix them in the holes of the hub at the moment it's all in my head I have to conceive the right proportions between the floor column upright and the cross arm on which to fix the spotlight, thanks for your precious suggestions, happy Easter ''

-

advice on construction of a DIY floor lamp in the shape of a stylized crane Hi, I had the unhealthy idea of building a DIY floor lamp in the style of a stylized construction crane to which to apply a spotlight or a lamp to use when necessary, but I don't know what measures to adopt and how to size it so that it is also functional, the arm it should be articulated to direct and direct the light beam where it needs to be illuminated, I had thought for the base of an old brake disc or a flywheel or a recovery gear of adequate dimensions for the upright in a style like a lattice structure for the arm crosspiece I don't know how to articulate and size it so that it is pleasant and functional. What do you recommend? Thank you and best wishes for Easter. Global Truss

-

I recommend repairing a roof with a DIY metal roof

angiolino replied to angiolino's topic in Problem Solving

-

I recommend repairing a roof with a DIY metal roof

angiolino replied to angiolino's topic in Problem Solving

I think I understood your thought I should create a frame to rest on the attic with a certain slope, screw the panels to it, if I'm wrong please correct me thanks https://www.sidernegri.it/images/pdf/tubi/tubi_rettangolari.pdf -

I recommend repairing a roof with a DIY metal roof

angiolino replied to angiolino's topic in Problem Solving

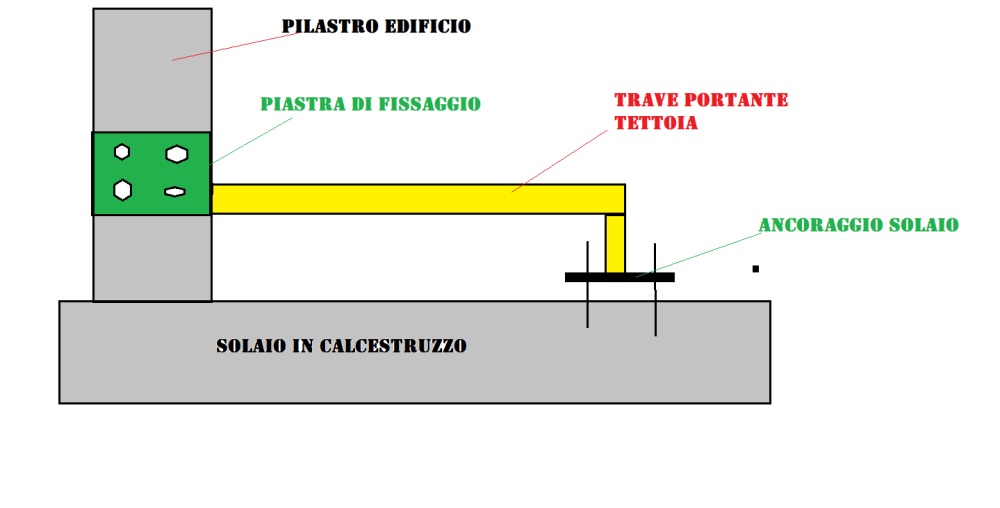

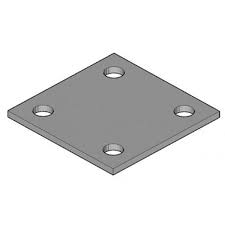

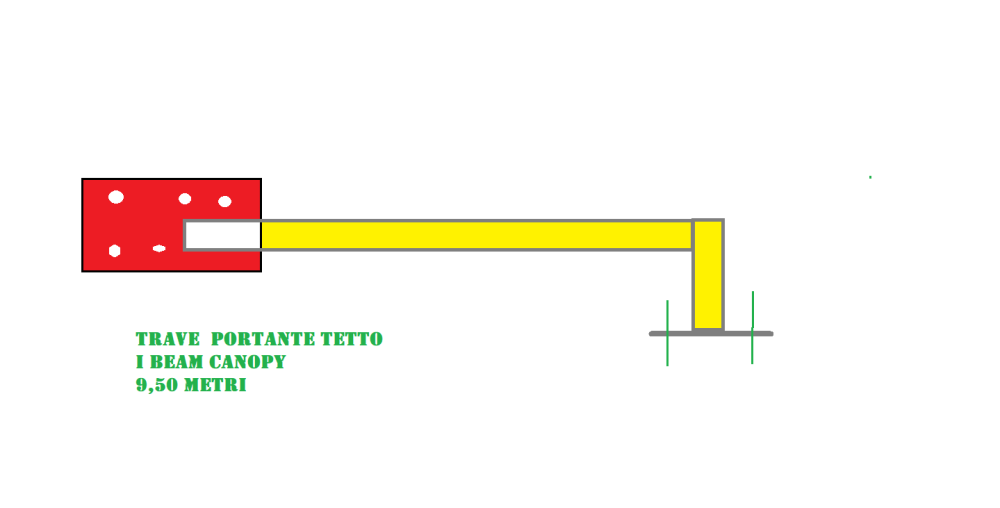

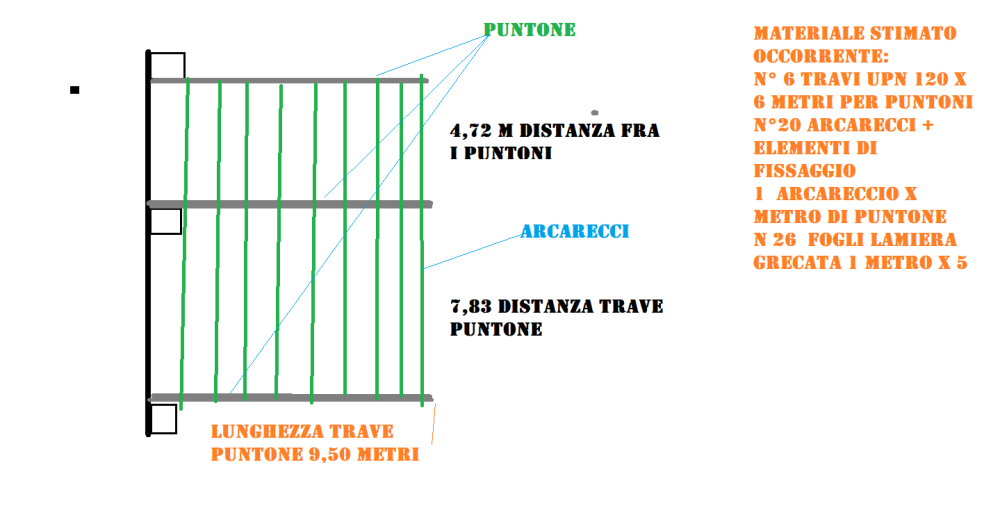

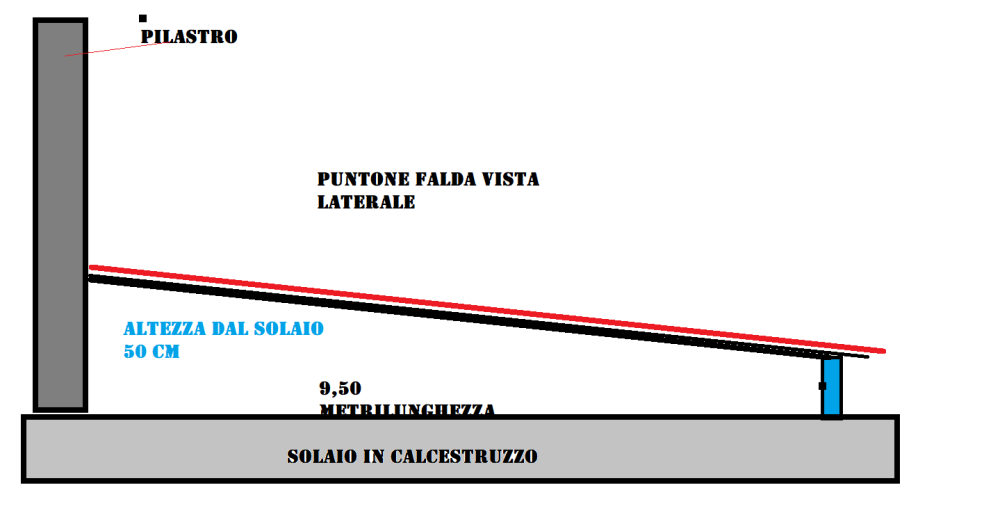

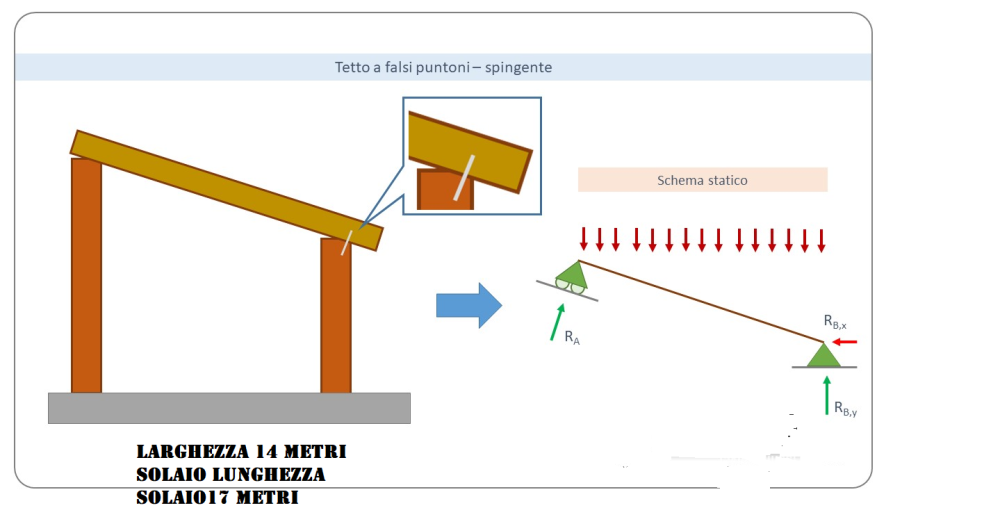

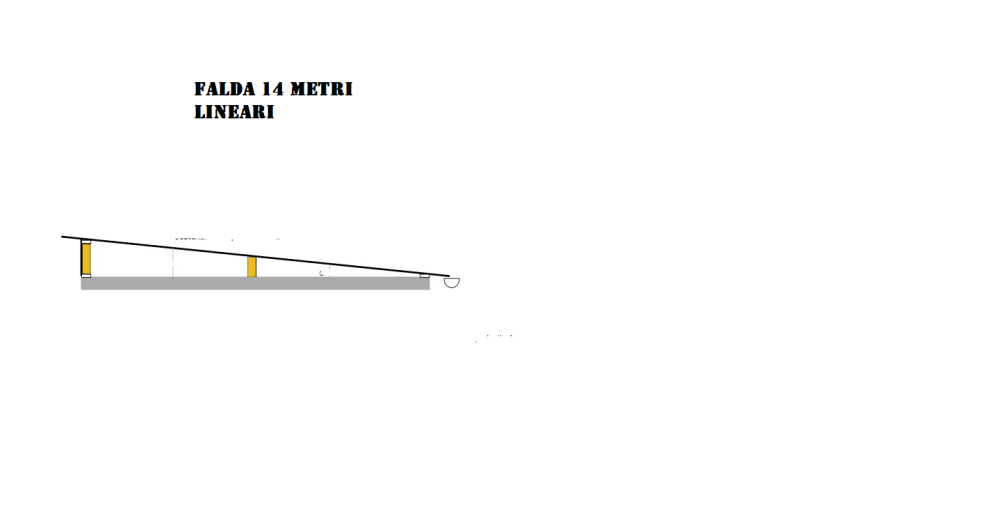

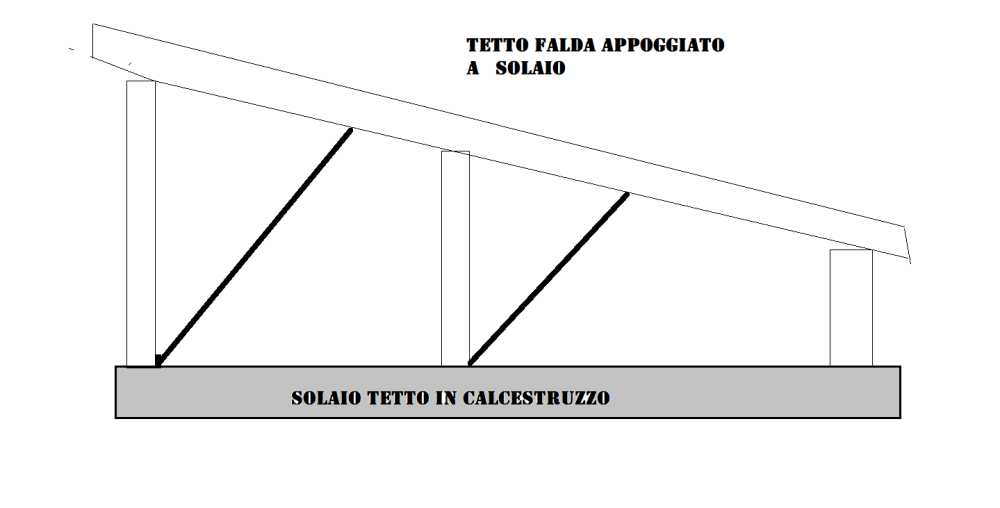

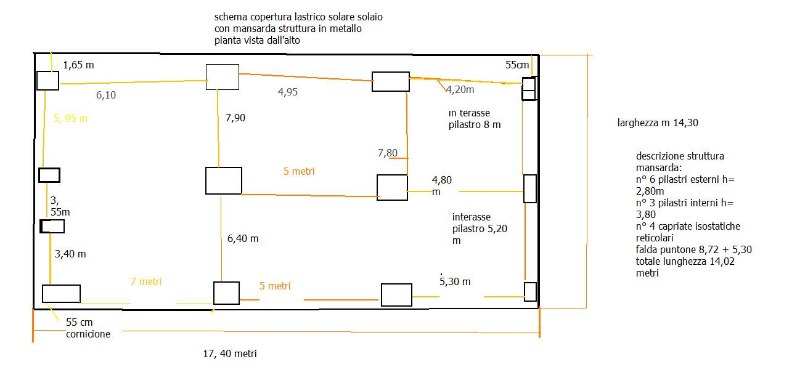

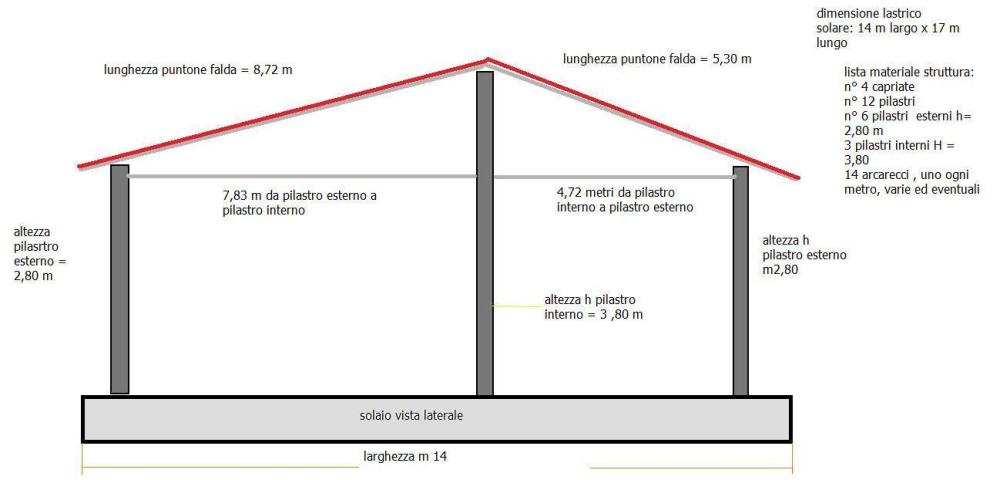

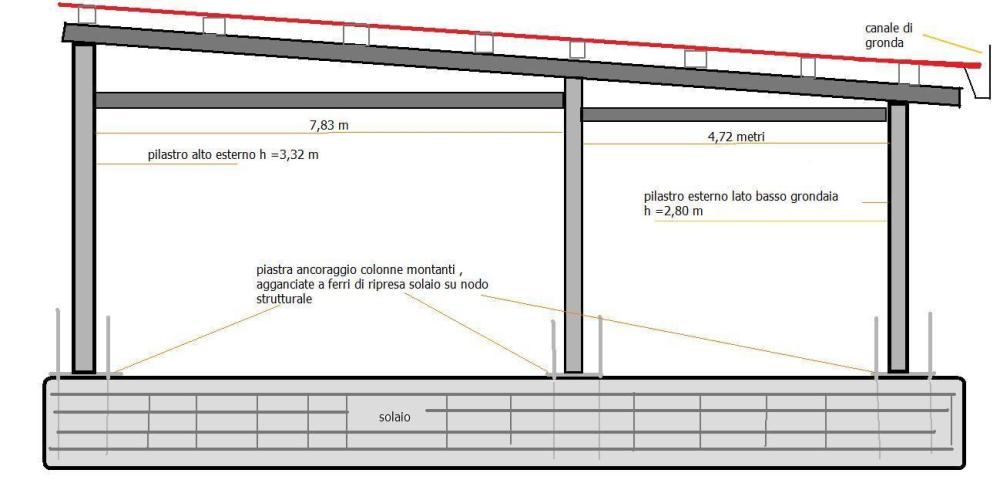

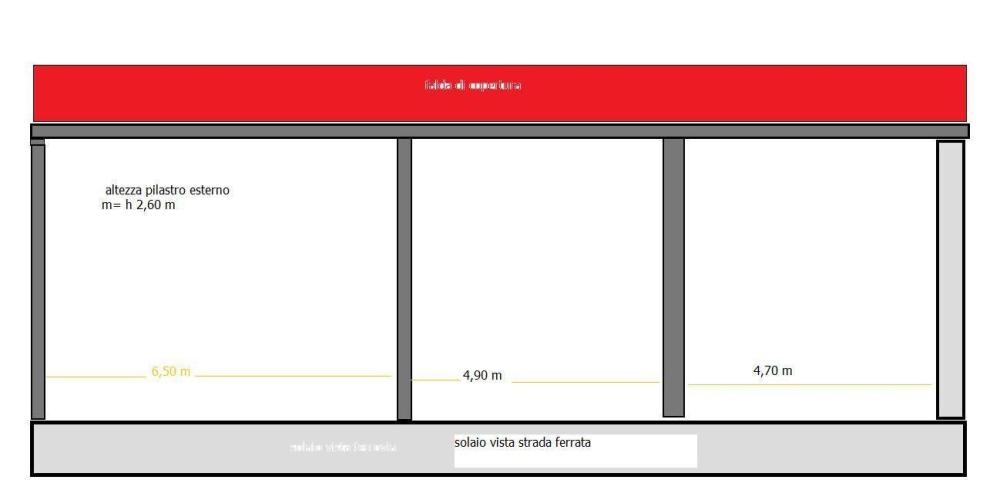

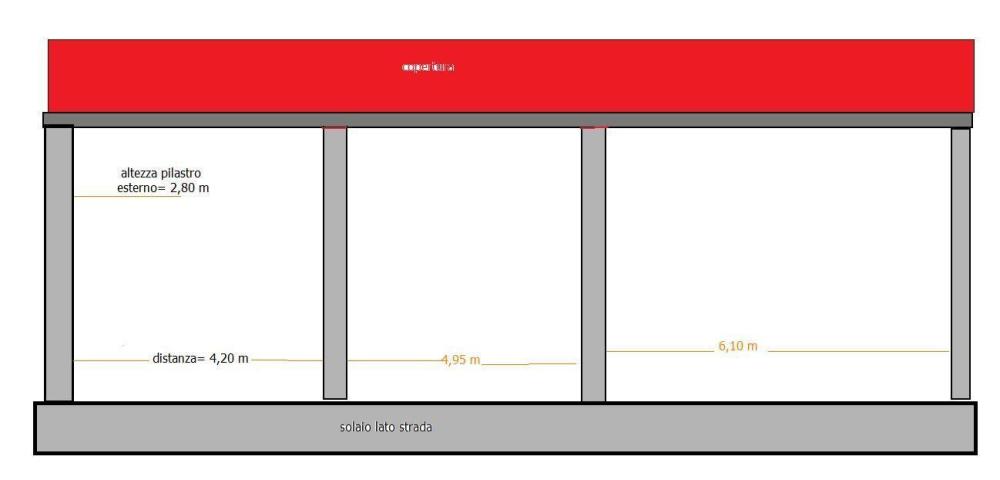

forgive me, I'm a mess, those three pillars on the opposite wall are from my building, the building was a single building and then it was gradually divided but I can anchor and hook up ok let's go back to the drawing 50 cm size of concrete pillars, linearly I have a distance of 9.50 meters in length is fine distance between the pillars on the short side 4, 72 metres, 7.83 on the long side is fine on the pillars I would like to attach with bolted plates, I was clear as someone perhaps you advised me let's start from the wall pillars with a height of 50 centimeters and half a meter to give the slope to the frame beams ok? problem the beams must be light but sturdy they are on the 2nd floor about 9 meters from the ground I only have to carry them so I have to organize myself. If you notice, I repaired the dormer window with a plastic cover like a shack last time I cut the pieces below and then assembled them above, climbing 5 meter wide panels of 1 meter at 10 meters above sea level was a struggle. they sell the beam bars in 6 linear metres, so I'll take them to 6 meter bars, I'll climb them onto the roof and weld them together to join them. I hope I've been clear on one side. I'll create something like an upright with a holding plate with holes to screw to the attic what do you think what do you think? I know I'm crazy. Either this or I'll have to weld the sheath onto a roll. the problem will be climbing 26 roofing panels. thank you sorry if I disturbed you -

I recommend repairing a roof with a DIY metal roof

angiolino replied to angiolino's topic in Problem Solving

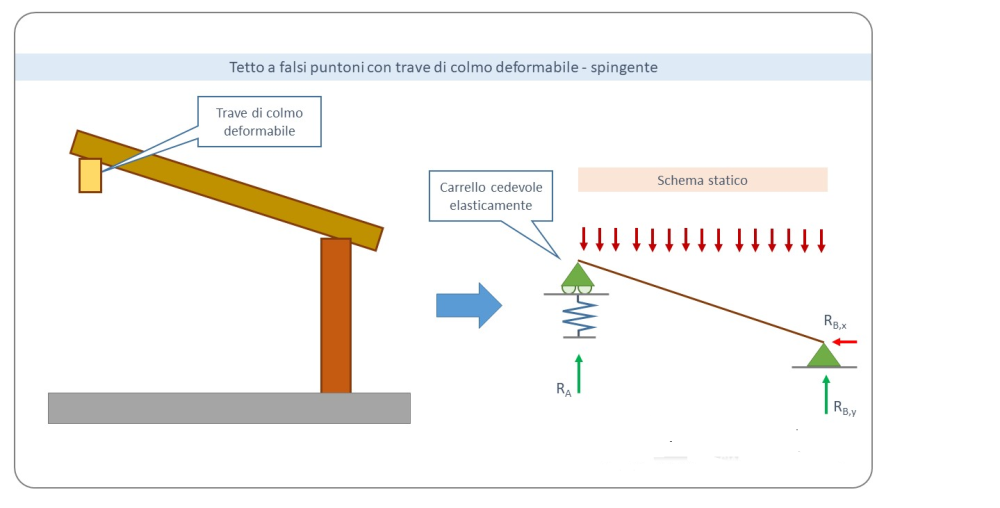

do you recommend the sheath? I had fantasized about putting struts attached to the pillars of the protruding wall and welding box sections to them. What do you think? Do you think it's feasible? Thanks -

I recommend repairing a roof with a DIY metal roof

angiolino replied to angiolino's topic in Problem Solving

in essence the house is an inheritance the other heirs don't care, (if they all don't care it falls down I'm poor so for me it's only one resource that I possess) I'm not being sarcastic obviously the translator isn't doing his duty I understand that I should consult an engineer, I just found out the crane costs €2000 per day to rent, I have to find a simple, economical and feasible solution, I welded the bituminous sheath but in summer the temperature exceeds 40 degrees therefore between extreme heat and strong wind it tears it away, when there is strong wind the action of the wind added to the rain is like the fire hose causes a lot of damage, sorry if I seemed sarcastic and rude thanks for your precious advice :EPDM waterproof membrane??? -

I recommend repairing a roof with a DIY metal roof

angiolino replied to angiolino's topic in Problem Solving

It's not that I like to build things myself, it's that necessity is the sharpest tool of ingenuity. I have to make a virtue out of necessity to create a work as illustrated by you. Between projects and permits I get about 25,000 euros, a figure that I don't have. I would simply like to put the strut beams anchored to the attic we weld the purlins across the beams and screw the panels to reduce costs, I understand well that if hurricane katrina comes and is not well secured it will fly away like a kite thanks anyway for your precious opinion https://farsuperov.life/product_details/6280897.html -

I recommend repairing a roof with a DIY metal roof

angiolino replied to angiolino's topic in Problem Solving

I don't have all this money, they won't give it to me to cut the bull's head since the house is old and no one is going to build on it. I had thought of cutting the reinforcing bars that come out and bolting plates to them in correspondence with the reinforced concrete beams. of waiting and to weld uprights onto them, not high columns, to give the slope to the pitch of the light roof is a mammoth job, they sell 6 linear meter beams, climbing on them would be a titanic undertaking, I had thought of creating a lifting scaffold to facilitate this work but it's all up in the air, otherwise I'll have to buy rolls of tar, weld the sheath next time, bad weather will tear them away, the gusts of wind and rain are violent, like a firemen's hose, I'm at the end of the line and I've wasted time and material money, you understand well, I'm desperate, thank you, sorry for the inconvenience. -

I recommend repairing a roof with a DIY metal roof

angiolino replied to angiolino's topic in Problem Solving

look I'm always there welding sheaths now the wind has torn a portion of them I have a flooded room, I had thought of cutting the reinforcing bars, making a frame adhering to the attic with a small slope and screwing the roofing panels onto it it's a life I've been fighting It costs a lot to call the company. I can't afford the expense. My financial resources are minimal. Thank you. Best regards -

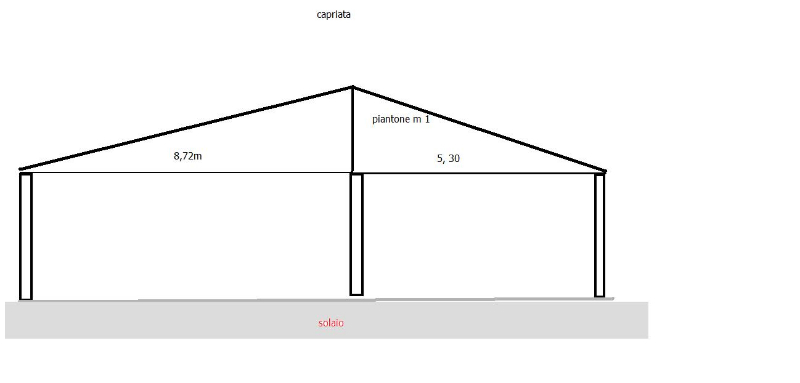

I recommend repairing a roof with a DIY metal roof: Hi, I live and work in an old 1950s building. I have problems with rain infiltration, I have tried to repair it in a thousand ways with hot asphalt and bituminous sheaths. I'm considering making a shed, a metal shelter and putting press-bent galvanized iron panels on it, I should make the frame supporting the trusses in essence, could you kindly provide me with some suggestions and solutions, thanks larga 15 metri lunga 18 metri

-

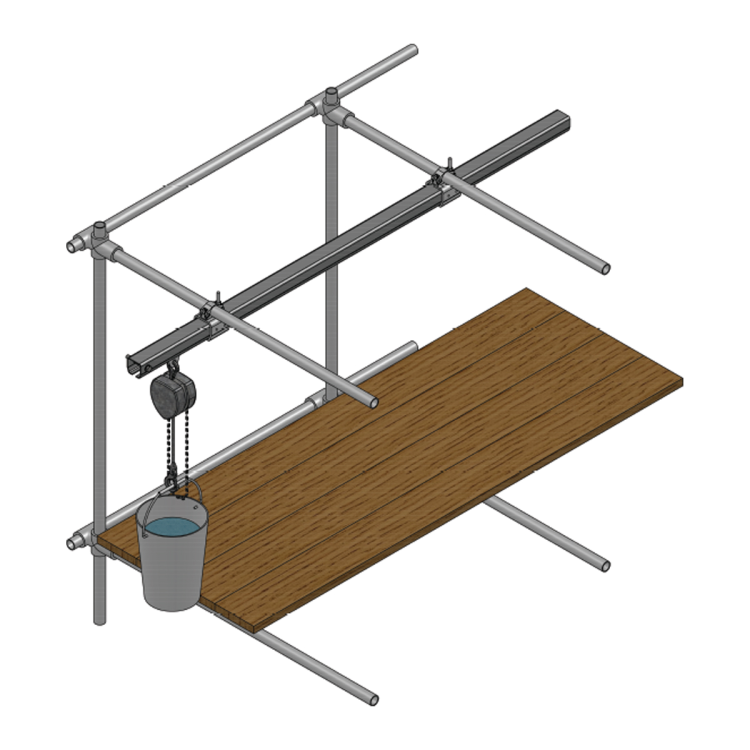

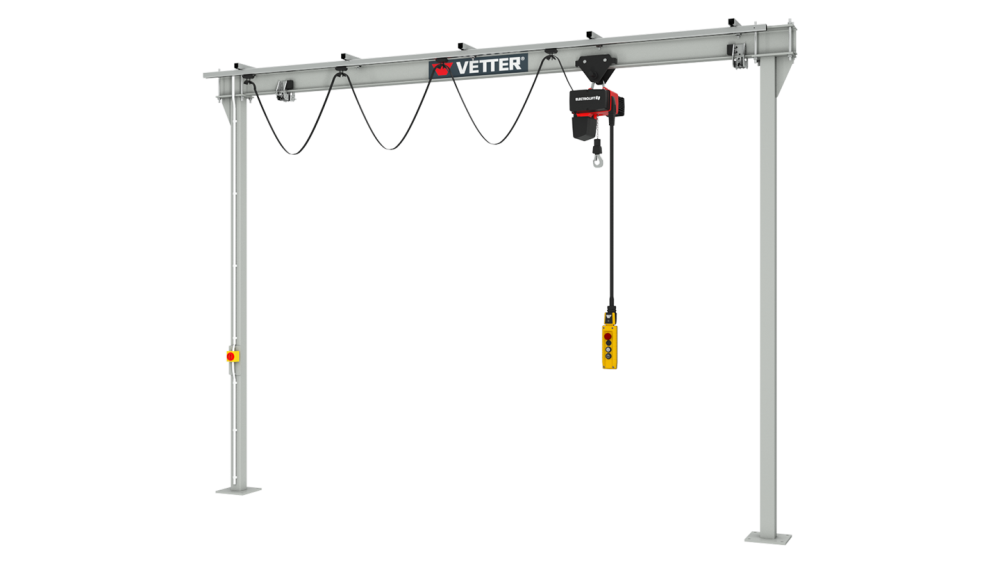

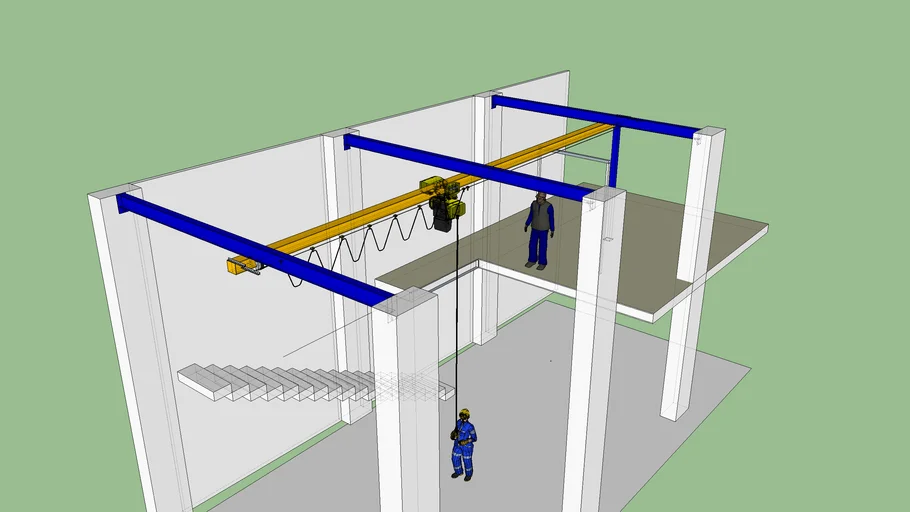

help advice fixed portal monorail trolley hoist for shed

angiolino replied to angiolino's topic in Member Projects

no everything manual push electric we need an engineer's project it's not our case we need it as a convenience in the garage thanks sorry for the inconvenience see you next time -

help advice fixed portal monorail trolley hoist for shed

angiolino replied to angiolino's topic in Member Projects

opens by unscrewing the threaded pin I got the hoist and the trolley I have to get the beam and the columns then I have to make the plates and the gussets thanks for everything sorry for the inconvenience -

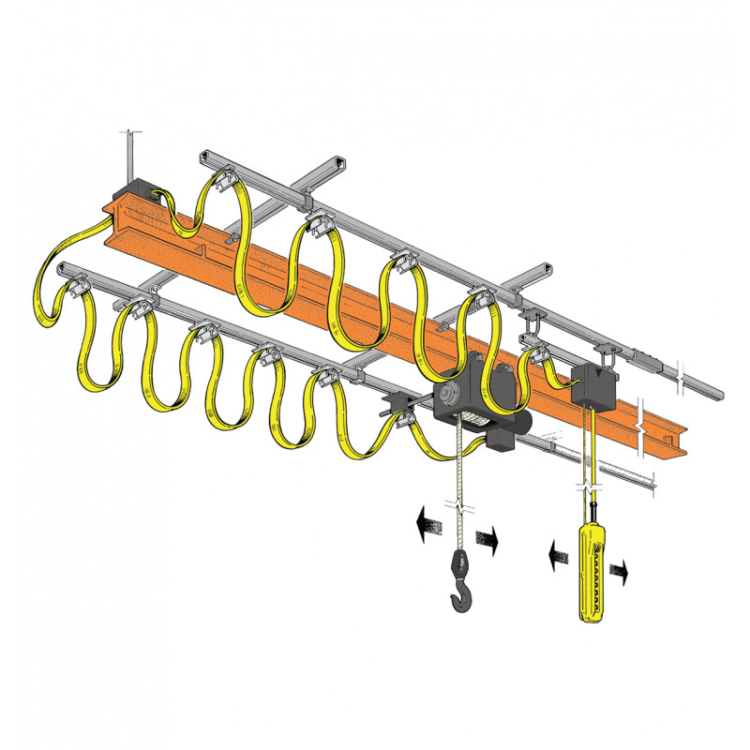

help advice fixed portal monorail trolley hoist for shed

angiolino replied to angiolino's topic in Member Projects

I already bought the hoist and the trolley, the trolley is adjusted according to the section of the rail beam -

help advice fixed portal monorail trolley hoist for shed

angiolino replied to angiolino's topic in Member Projects

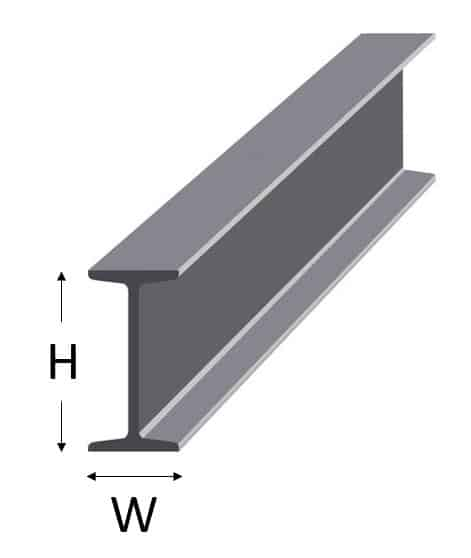

Thanks for the valuable suggestions. I'm sorry again if I don't actively participate in the forum. Greetings ps, column 120 mm, crosspiece 200 mm did I understand correctly?