-

Posts

290 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Cerritos, CA

-

Interests

Bushcraft, Archery, Fishing, Wood Carving, Leathercraft, Art.

Recent Profile Visitors

-

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

Nice work JHCC, I really like that knitting bowl. -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

Good stuff Bryson! Funny you posted that, I've been thinking about treble hooks these last few days. But for no particular reason. -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

Excellent as always alexandr -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

Made some pickup tongs for the first time, these were one heck of a challenge for me, but they work. Just not pretty. Also used some Ken's iron tong blanks to make something for small wire. Inadvertently ended up with small wolf jaws. -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

Good work BEJ431, Those are the Ken's blanks right? -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

Glenn, thanks. She's a little slow on the topic for some reason. Despite a photo and multiple detailed descriptions, she can't grasp the idea. I've gotten measurements of "3, 3.5, and maybe 4 inches" . I don't see her often, so it's tricky. At this rate I have to catch her in person. Quite the mission so far. haha Excellent work lemarechal! -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

Rojo Pedro: thank you, yes it's brass. I screwed up on it, thankfully that was just the test piece. It was originally supposed to be domed, but got flattened after a little too much oompf. Steven NY: thank you, I've seen many people before me do it. But my original inspiration was from Jackob Faram. He makes awesome little keyrings using this method, except he does it 100 times better. -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

Two more bangles today, starting to understand these a little better now. This was supposed to be something for a birthday gift at the request of my sister. Unfortunately my she cant figure out how to measure her hand circumference, so I'm stuck making multiple sizes for now. Good practice for me, but troublesome when a basic task all of the sudden becomes a big ordeal. -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

Thanks Frosty. I had a heck of a time working on that wrapped area, in fact, I spent more time on that, than I did the entire thing. -

What did you do in the shop today?

Mudman replied to Mark Ling's topic in Blacksmithing, General Discussion

-

Show me your Bottle Openers!

Mudman replied to Arbalist's topic in Blacksmithing, General Discussion

haha you guys crack me up! -

what have you gained from blacksmithing

Mudman replied to pnut's topic in Blacksmithing, General Discussion

It's been most humbling and relaxing of my many hobbies. I get more satisfaction forging a scroll, than I do making a stock removal knife. My father passed in November of last year, he raised me to use my hands and work hard. Blacksmithing really makes me feel like I am doing both. As of late it's what I've had time for (albeit not much), since knife making has been put on hold for now. While my father never forged, blacksmithing reminds me a lot of him, for which I am grateful. It's also helped me see things more dimensional, which has always been trouble for me. I used to be only able to envision the making of things in 2d before. -

Making Nails with illustrations

Mudman replied to Mudman's topic in Blacksmithing, General Discussion

ohh okay I get what your saying now. Thank you very much, the illustrations really help. The topic does lend itself well to nails. It's kind of like using a mango to describe a shape, all the while saying to myself "mango sounds good right about now". I get distracted a little too easily. So pictures/drawings really help me understand better. -

Making Nails with illustrations

Mudman replied to Mudman's topic in Blacksmithing, General Discussion

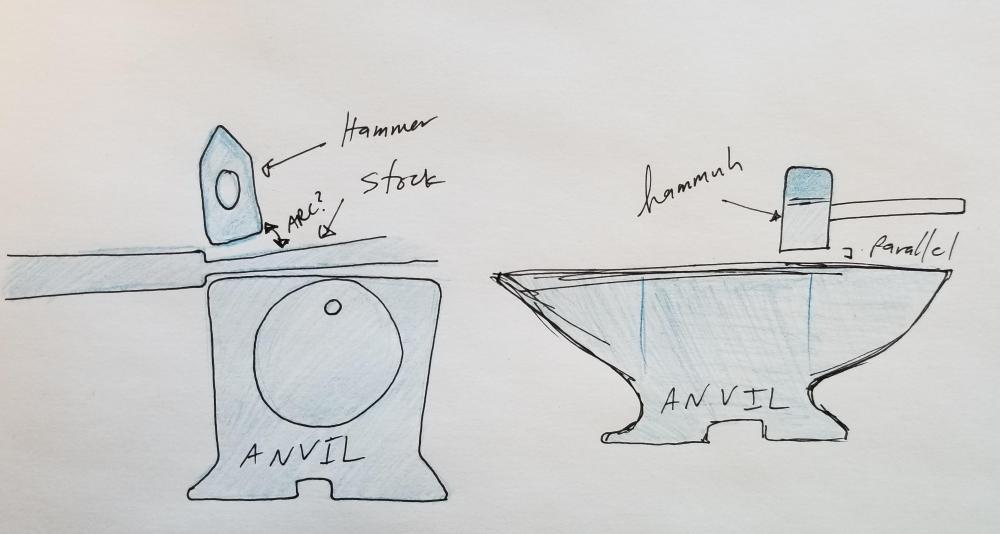

indeed, I do my best to take everyone's advice. It's the only way to improve. If I didn't- the things I work on would look VERY different, and not for the better. Yes I've watched them, but have some gaps between when I do and when I attempt to apply. So sometimes I forget. In this instance- I wasn't aiming to make nails, so it didn't occur to me to reference your video. There's lots of little nuances that often get missed, unless I'm particularly looking for it, again this doesn't always occur to me. Tapers I normally do forge over the far edge, or the horn. I haven't worked on a 4 shouldered boss yet- although I think I'll practice that tomorrow. When you say arc the hammer, are you referring to tilting it towards me? I forge parallel with the anvil, although dance around a lot also. I shall work on these methods, and update with new video. Thanks for the tips, I'm always learning something from you. =) -

Making Nails with illustrations

Mudman replied to Mudman's topic in Blacksmithing, General Discussion

Thanks jlpservicesinc, I wasn't aiming to make nails truthfully. Just sorta worked out that way. My goal for the day, was specifically practicing right on the edge of the near side. As for forging cold/black heat, it's not something I regularly do, just showing/wanted to share a video- although I realize that was a bad example. The hardy cut is made of S7. Sorry for setting a bad example.