KeithSS

Members-

Posts

41 -

Joined

-

Last visited

Profile Information

-

Gender

Male

-

Location

Ironwood,mi.

-

Interests

Going to heaven,machining,repousee,blacksmithing,motorcycles,bow hunting,lapidary,wood turning.learning more.

Recent Profile Visitors

2,134 profile views

-

Just read the replies, thanks. After getting a vibrator, and buying different media I wasn't satisfied. So built the 5 gal.bucket tumbler. I did put in two 1by2 boards to drop the media when it reaches the top. i don't think I have enough media in it. I will try some nails that I have . The ballcones sure are pricy. The noise is really loud. I only run it at night because I don't want to hear all day. These tumblers have to be set up just right from what your saying. I bought this disk for my 4 1/2" grinder and it is taking the scale off very fast and it looks like it was just lightly sanded. It is a woven material so it should be used with a mask. Until I get the tumbler stars all aligned . I'm gonna just use this disk and a slow wire wheel. Yep, it doesn't matter how good of work you do, if you don't Finnish it nicely. Type 27 Grinding Wheel, 4 1/2, 7/8 NORTON Zoro #: G4415381

-

Hi, I have been making hooks ,and it takes as long to wire wheel them and wax them as it does to forge them. So I made this 5 gal.bucket as my tumbler. My question is now, how do I use it? What type of media should I use to descale? Should the bucket be 1/2 full or 3/4 full of media? Also, should I put some thin cuts in the bucket to let the dust out? Thanks for any help you can give me. Keith

-

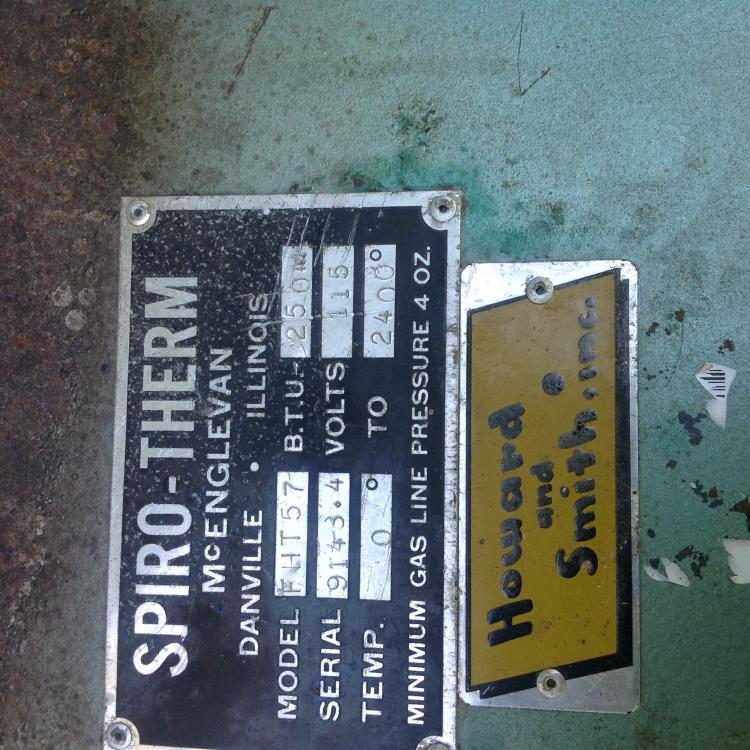

Yep, the mfg. said it was supposed, To read 250.000 btu. Not million.

-

I will ask the company if its millions or if its thousands of btu. Thats a good point . I have seen boilers rated in the millions , but they had a 4" gas line going to them with a big gas pump. It's a 3/4" fitting going into this unit. I think the strength of this forge is the shell and firebrick, it has 2 gas lines coming in the top side of the shell and on the other side 2 gas lines going in the bottom and it must make a swirling movement. Rated to 2400 deg. The brick is all curved round and in perfect shape. i ordered a $100 dollars worth of parts a spark plug ignitor and a flame sensor. im thinking if it doesn't start, its going to be the fire eye box which I'm thinking its a $500 dollar part . Then I might have another machines skeleton standing in the corner of the shop taking up room.

-

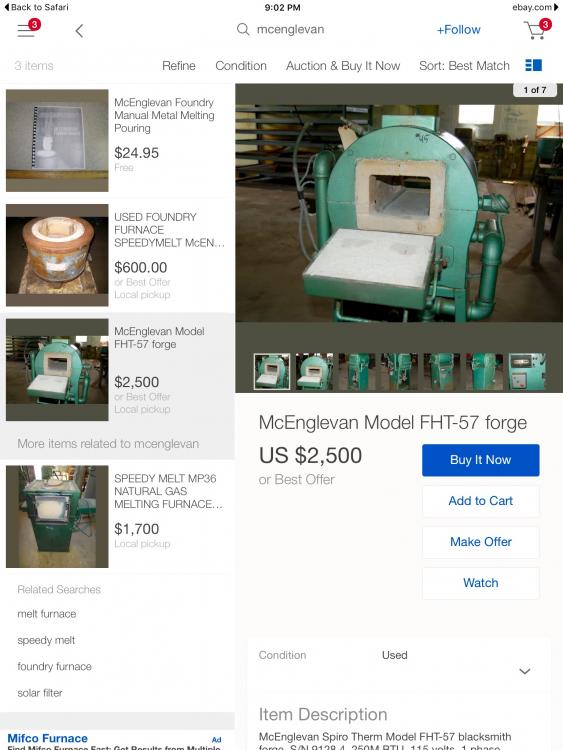

I didn't pay $2500 for it .i got it for a couple hundred . I was just Useing ebays pictures. The company that makes these said , the new ones are built the same as the old ones except for the electronics are updated. So, I couldn't figure out how to see what the cost to operate it will be. The name plate says 250 m btu. 1.000.000 btu = 10 therms = $9.00 I pay 90 cent a therm in mi. (How long does a therm last?) i know it can't cost as much as my math says.

-

I will do that formula and figure out what it will cost. Thanks

-

I do forge everyday. Mostly 1/4" 3/8" 1/2" steel and railroad spikes size is about my limit. Natural gas is cheap now, I thought that if it runs off nat.gas it would be cheaper to operate. I use around 300 gallons of propane a year. i built a ribbon forge and fired it up a few times , I only had 1" of kaowool in it and it got very hot very fast. I was just experimenting with it. And now I'm adding refractory 3000 on the walls of it. Don't take this personally, but do you know for sure that the Spiro-therm forge would be a gas hog? Thanks

-

Hi, was hoping someone had experience with one of these forges. There is one on eBay for $2500. I just got one in good shape needs some parts and some work. I really like that this forge use propane or nat.gas.its all automatic as far as adjustments ,set the temp and go. I do guess that this is how it works. I have been forging from a aspirated propane forge and it works great for me. im just wondering if this forge is worth spending time setting up and Useing as my daily forge? heres some pics.

-

Dropped 25# little giant when moving

KeithSS replied to KeithSS's topic in Power Hammers, Treadle Hammers, Olivers

Got the old pulley welded on for $45. Dollars. Couldn't quite figure out where to get a pulley to put on after turning a shoulder. The welder said it was good cast iron ,no sand in it . If this breaks then I will pursue the other option of finding a pulley with 2 grooves to have machined on. Yes, I am very fortunate to have only broken the pulley. Will let you know how it works after installing. -

Dropped 25# little giant when moving

KeithSS replied to KeithSS's topic in Power Hammers, Treadle Hammers, Olivers

Found a guy who is going to weld it for me. Let you know how it turns out. Thanks for all your help. Keith -

Dropped 25# little giant when moving

KeithSS replied to KeithSS's topic in Power Hammers, Treadle Hammers, Olivers

I think it maybe cheaper to fix it like peacock posted. Its just locating the right size pulley. I checked ebay And surplus Center , I just need to figure out exactly the best way to get it to fit the hub or clutch. -

Dropped 25# little giant when moving

KeithSS replied to KeithSS's topic in Power Hammers, Treadle Hammers, Olivers

Yes it is a jardin. Artist I read your post on welding cast iron. Much more to it then realized. I did think about taking off the rest of the pulley and just getting smaller belts. Peacock ; I like the new pulley shouldered up and bolted on. Where is a place to get a 2 groove pulley from like that? Would you happen to have a picture of the other side of the pulley? I'm wondering if I have enough metal to turn a shoulder into? Thank you , Keith -

Dropped 25# little giant when moving

KeithSS replied to KeithSS's topic in Power Hammers, Treadle Hammers, Olivers

Thanks for the info and offer. I'm going tomorrow to a machine shop where a couple of old timers work. Hoping they will like a challenge. They may have some material that may also work. -

Dropped 25# little giant when moving

KeithSS replied to KeithSS's topic in Power Hammers, Treadle Hammers, Olivers

Yes I also think it is repairable. Do you think a minumum of 1/8" wall thickness would hold if screwed together and braised ? I have brazed steel but not cast, I know it must be preheated ,should I grind a channel around the cracks to have more brass adheishion ? Here are more pictures -

Dropped 25# little giant when moving

KeithSS replied to KeithSS's topic in Power Hammers, Treadle Hammers, Olivers

Braising is what I will do to hold it in place . I will need to find a piece of 10" x 3 1/4"steel pipe to put over old pulley ,then drill and tap into cast,to fold it together . I took Sids class a few years ago , strange I brought the parts to ask his opinion of them , he said they all looked ok but, you can't get this part anymore.(the part I broke.) The saying ; Haste makes Waste is a reality to me now. I think I have done my very best work when I've taken my time. Do you know where I can buy a piece of steel pipe this size- 10" ID. X 3:1/4" wide x 1/8"-1/4" or any smaller thickness? (My other thought was to grind the rest of the broken pulley off and use the hub for a pulley? Any thoughts on that idea?) Thanks for your help and ideas.